Some computer simulations:

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

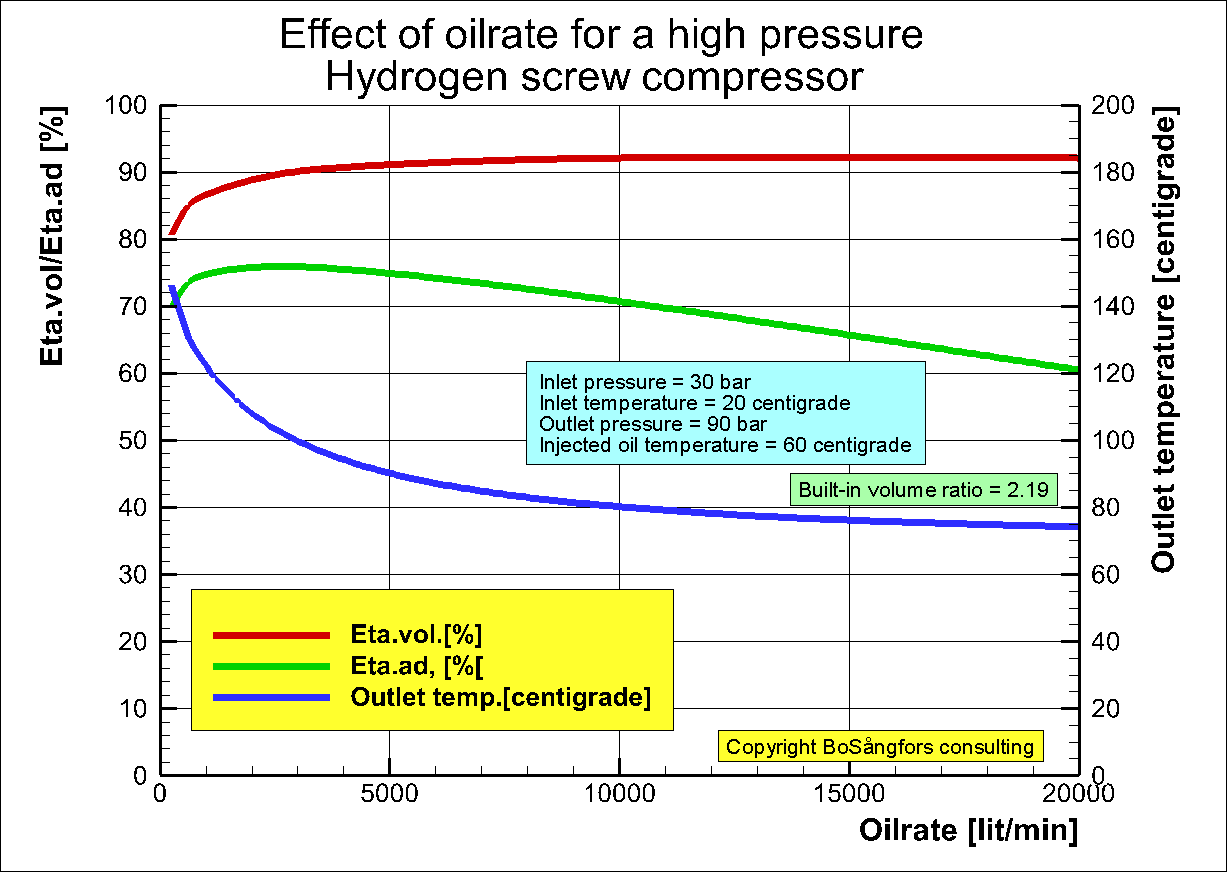

Effect of oilrate for a high pressure HYDROGEN screw compressor

working with inlet pressure 30 bar and outlet pressure 90 bar

Input data:

Gas=Hydrogen

Pressure in = 30 bar

Pressure out = 90 bar

Temperature gas in = 20.0 centigrade

Temperature injected oil in = 60 centigrade

Built-in volume ratio = 2.19

Rotor diameter = 400 mm

Male rotor tip speed = 79.6 m/s

-------------------------------------------

Calculated results

-----------------------------------------

As can be seen from fig.1 the best adiabatic efficiency is

at oil injection rate 3000 lit/min.

Outlet temperature is at that point 99.8 centigrade

Increase of oil flow increase the outlet flow losses which

increase the power consumption

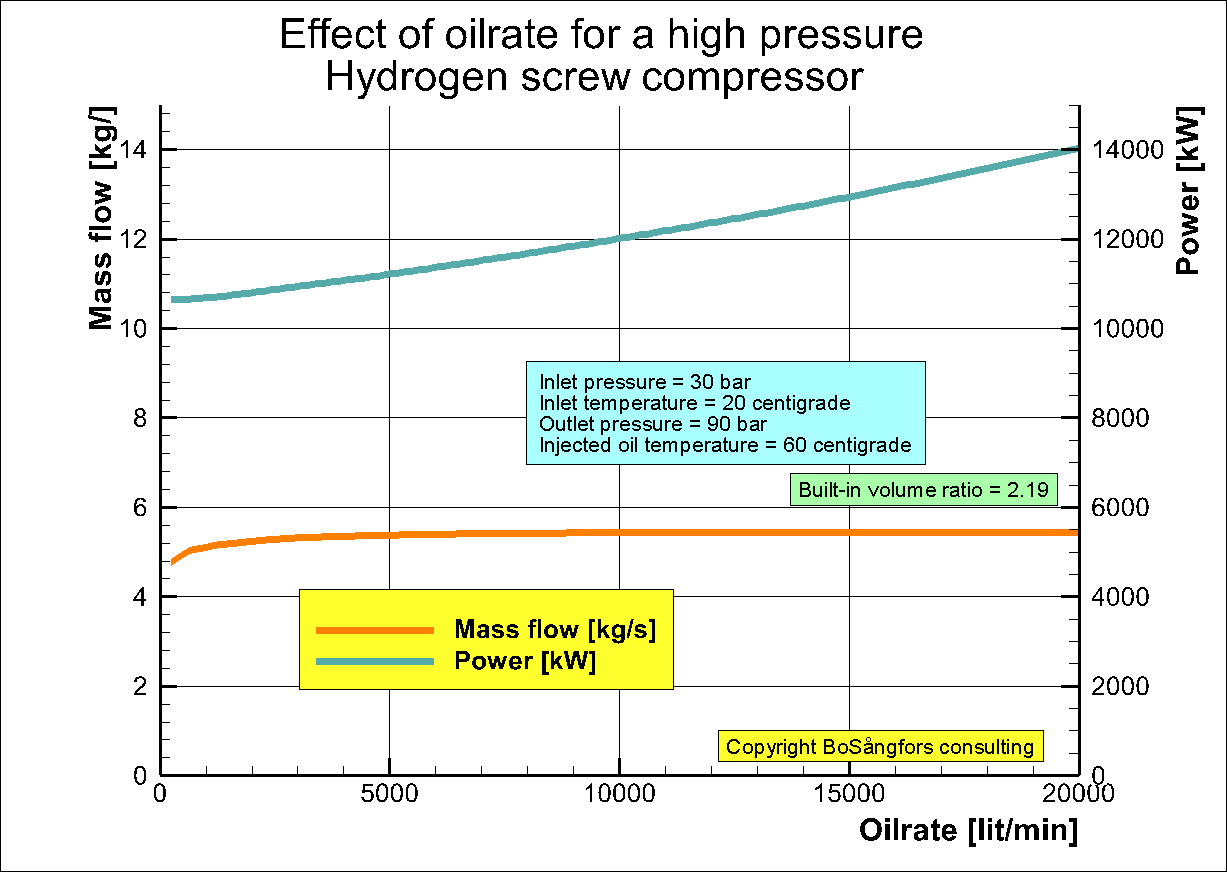

The mass flow is almost constant above the optimum adiabatic

efficiency point. See fig.2.

Fig.1

Fig.2

Performance at the optimum

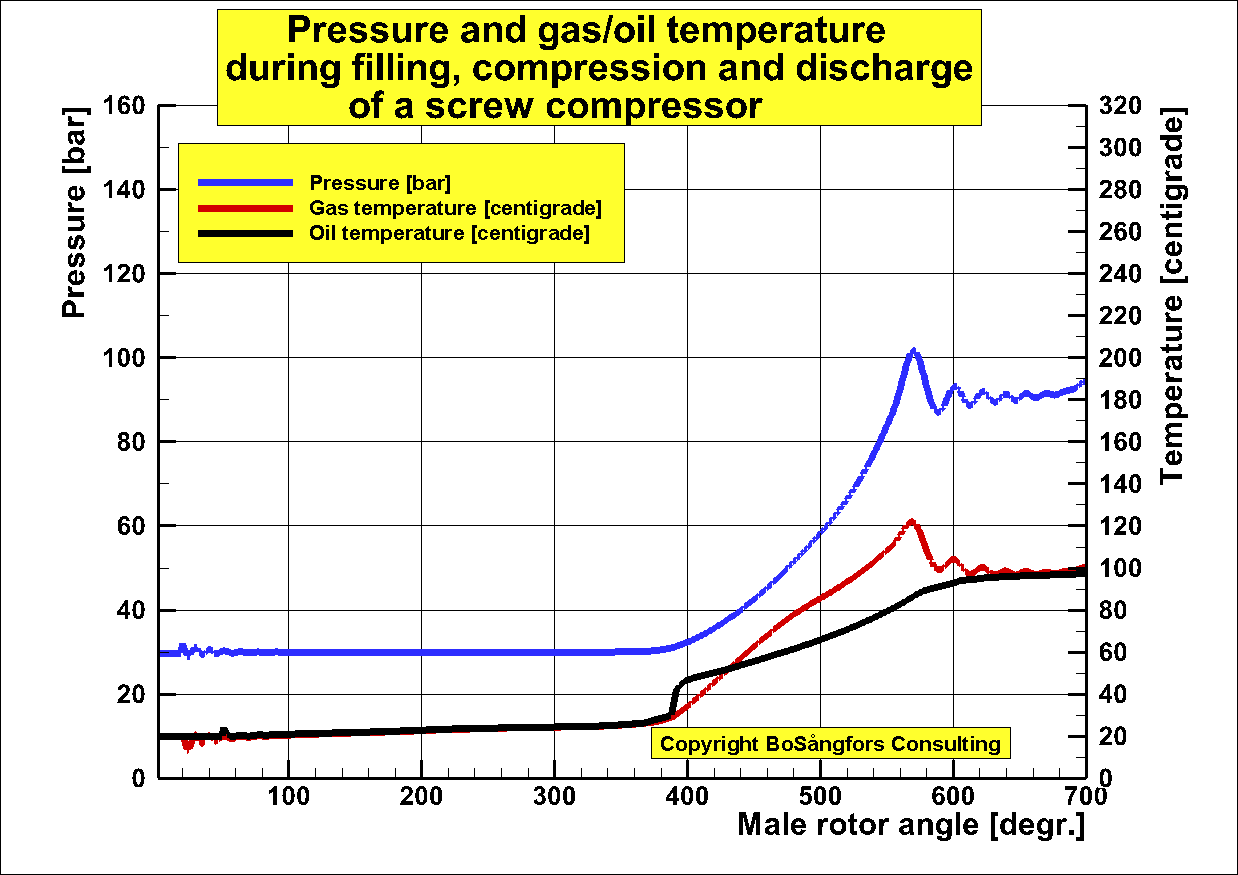

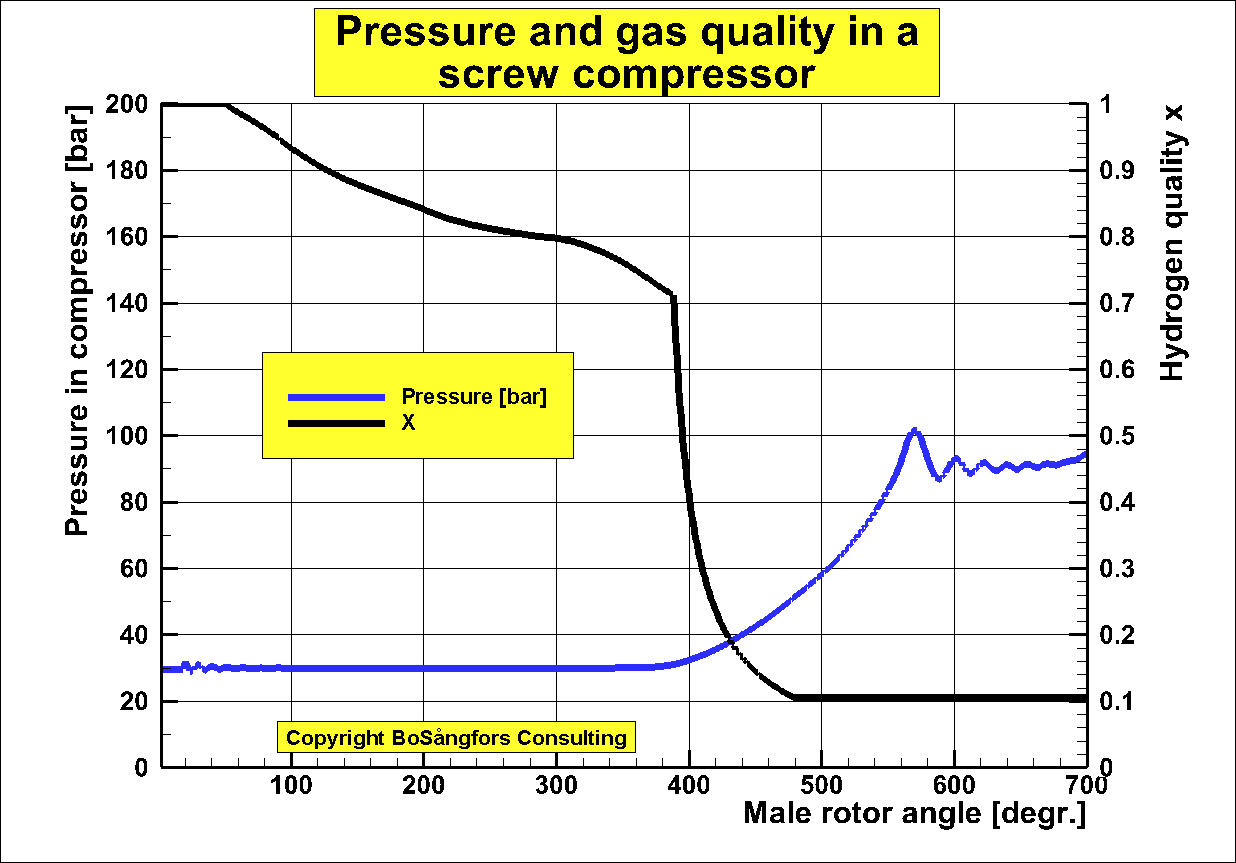

adiabatic efficiency point are presented in fig.3 and 4.

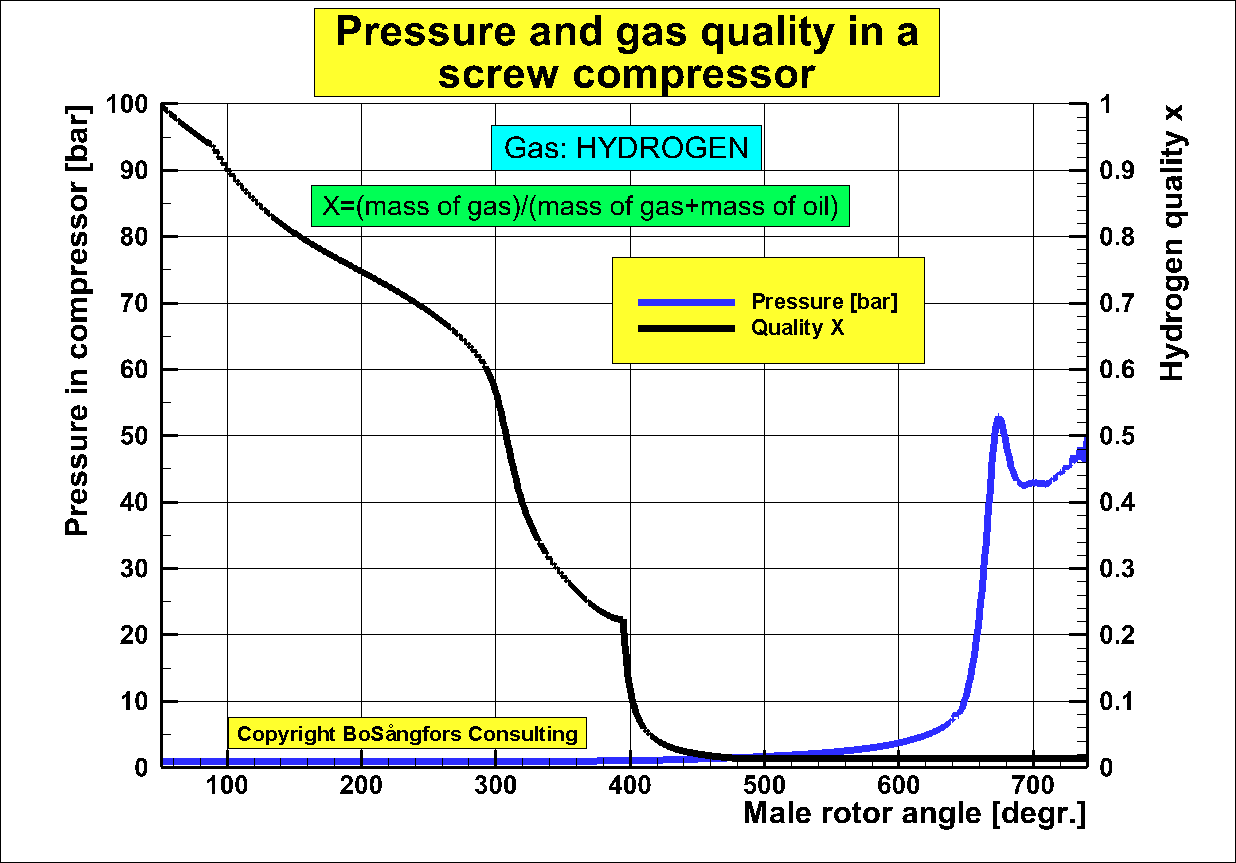

Regarding fig.4 gas quality X is defined as X=(mass of gas)/(mass of gas+mass of oil)

Fig.3

Fig.4

-------------------------------------------

Performance at best adiabatic efficiency -----------------------------------------

Volumetric efficiency = 0.901

Adiabatic efficiency = 0.759

Outlet temperature = 99.8 centigrade

Hydrogen mass flow = 5.317 kg/s

Power consumption = 10940.3 kW

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

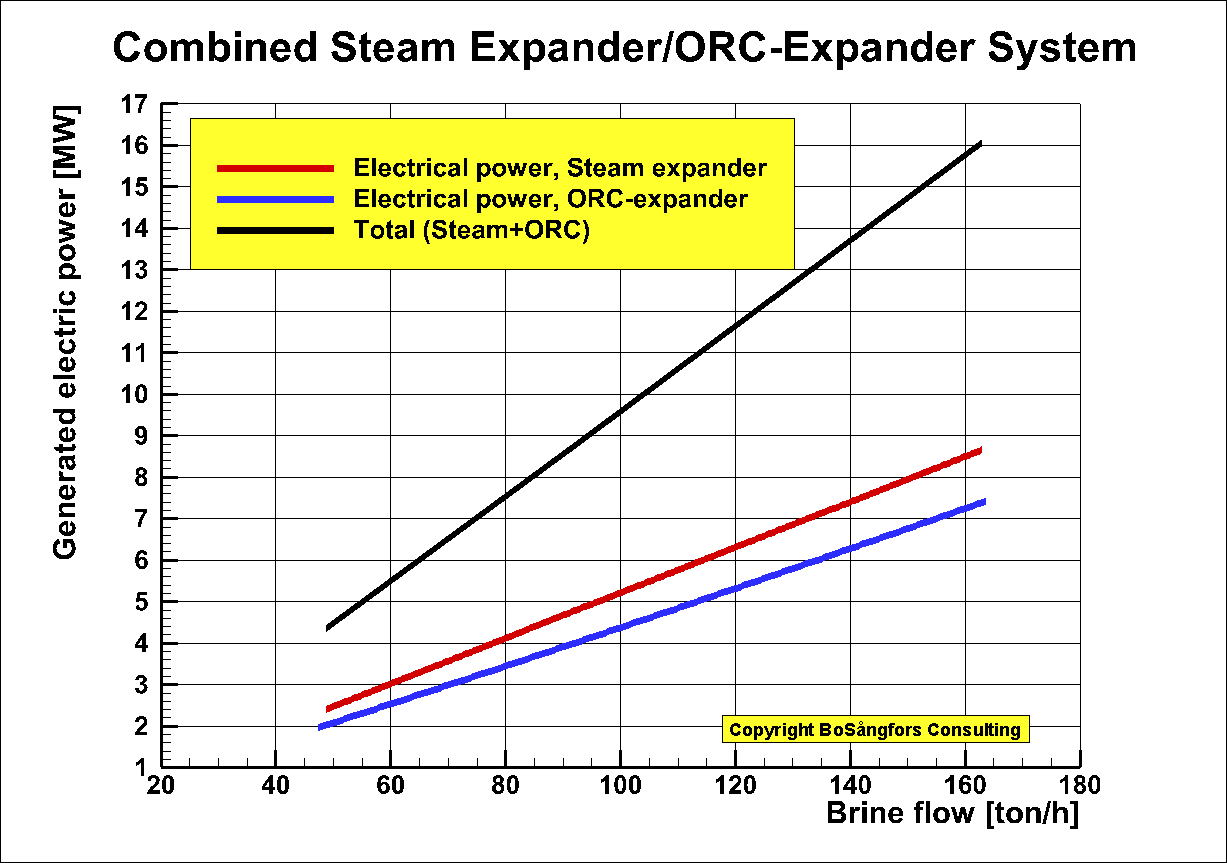

GEOTHERMAL

Heat

recovery from low quality steam using twin screw expanders

The intension of this set up of calculations is to show

that it is possible to get reasonable results from a heat

source of low quality

if you expand the steam to a lower pressure.

Hereby you increase the steam quality enough to use the steam as inlet to a

screw expander.

Stage 2: ORC using R134a Screw Expander, Diam. = 948 mm, Inlet x=1.0

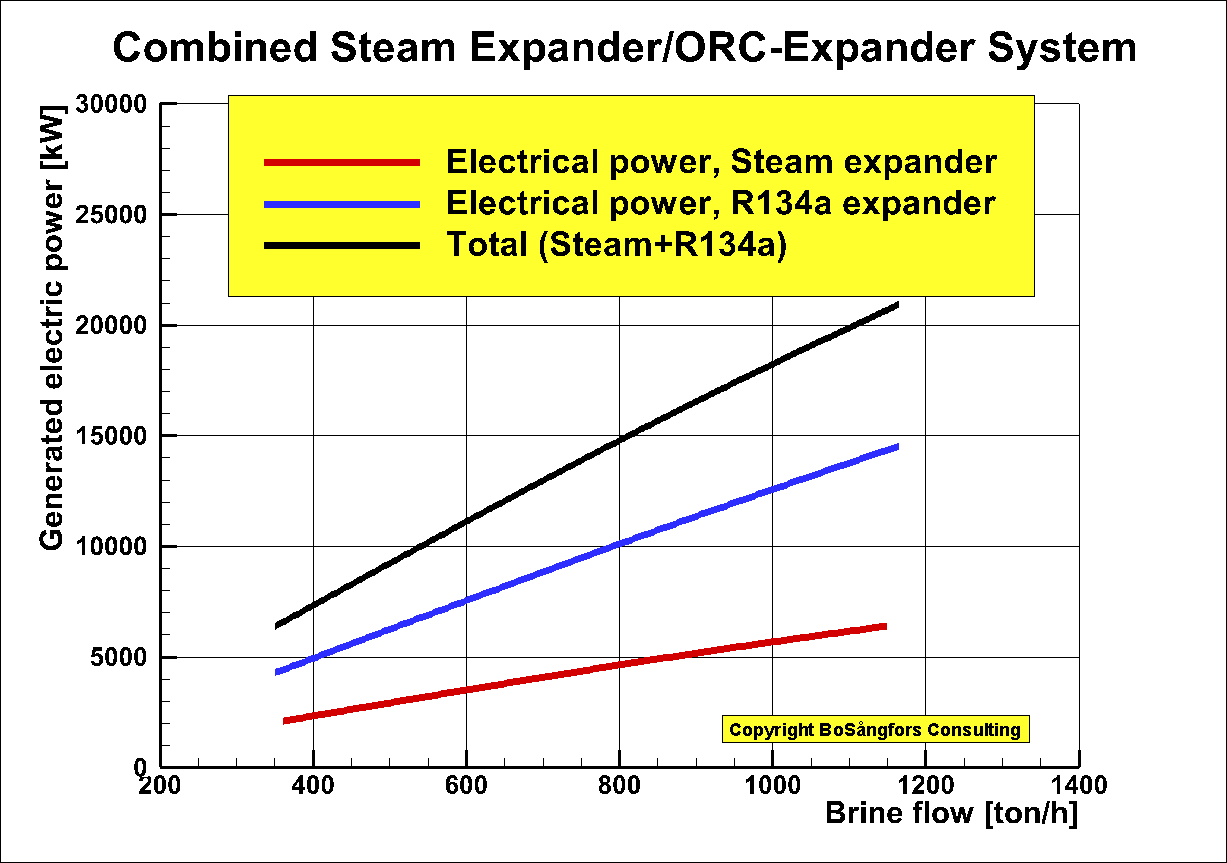

Fig.1 shows the total generated effect as a function of the brine flow in the

system.

Fig.1

Stage

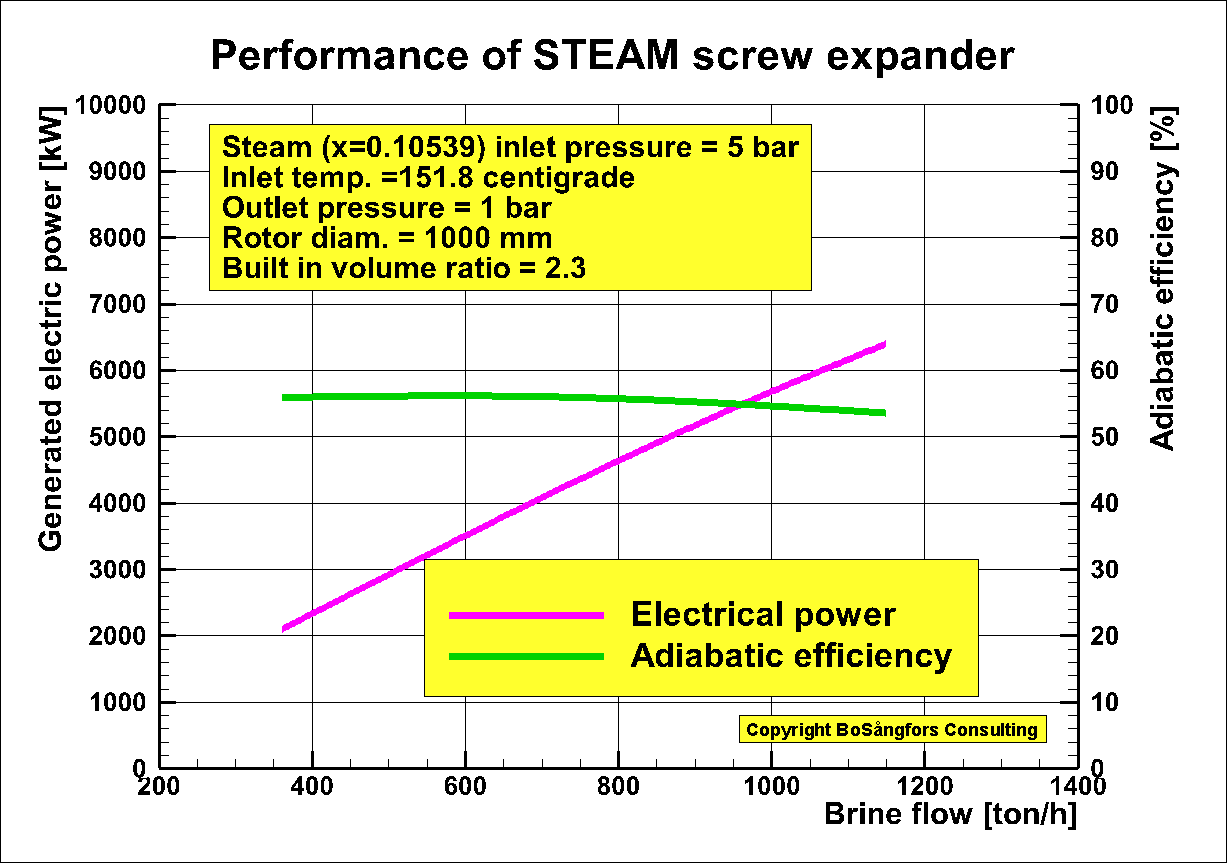

1: Steam Screw Expander in above Combined System

NOTE: Since this steam expander operates with low steam quality (x=0.10359 at inlet) water lubricated rotors might be used instead of synchronizing gears.

Fig.2 shows that the generated effect and the adiabatic efficiency as a function of the brine (steam) flow

leaving the steam expander.

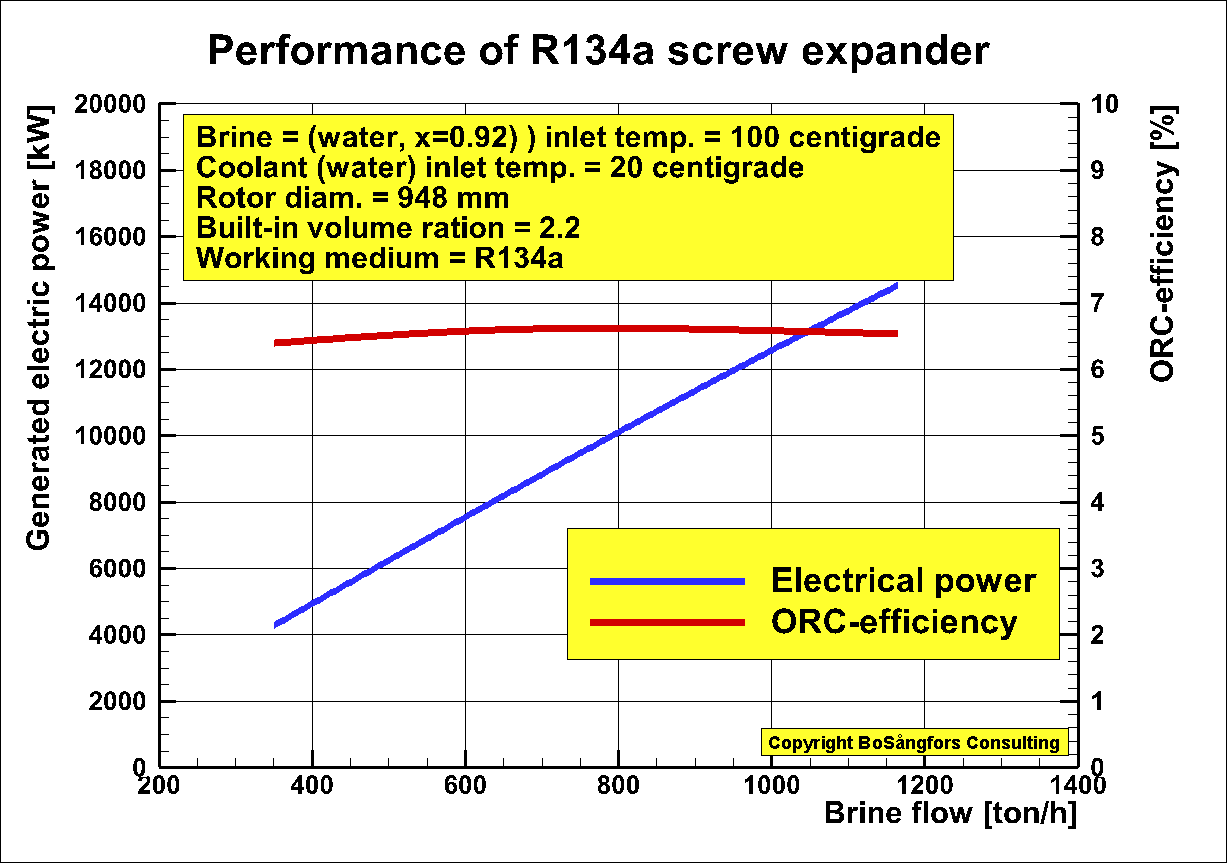

Stage 2: ORC using Screw Expander

in above Combined System

Coolant = Water

Coolant temp in = 20 centigrade

Evaporation temp = 85 centigrade

Condensing temp = 30 centigrade

Condensing pressure = 7.702 bar

Temp. efficiency (Evaporator +Preheater) = 90 %

Temp. efficiency Condenser = 90 %

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

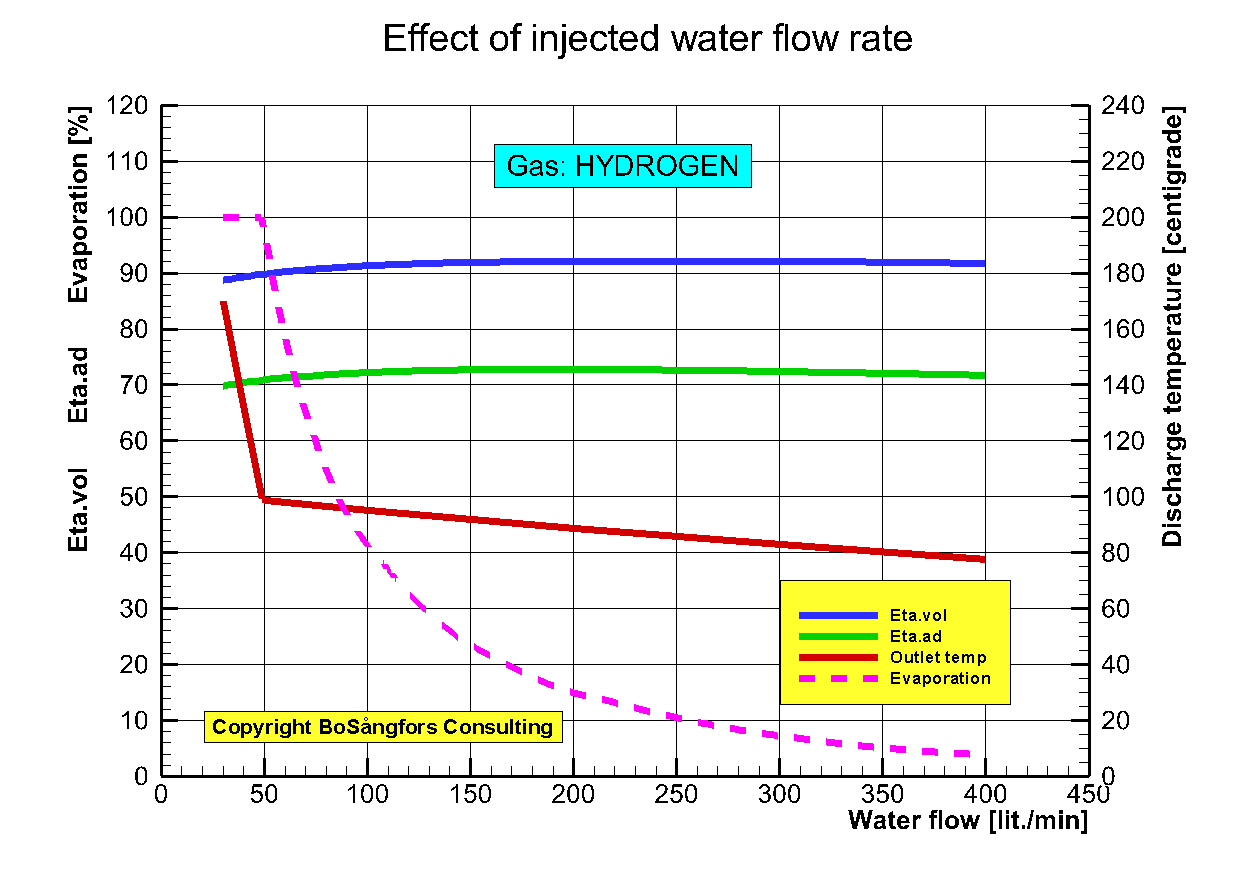

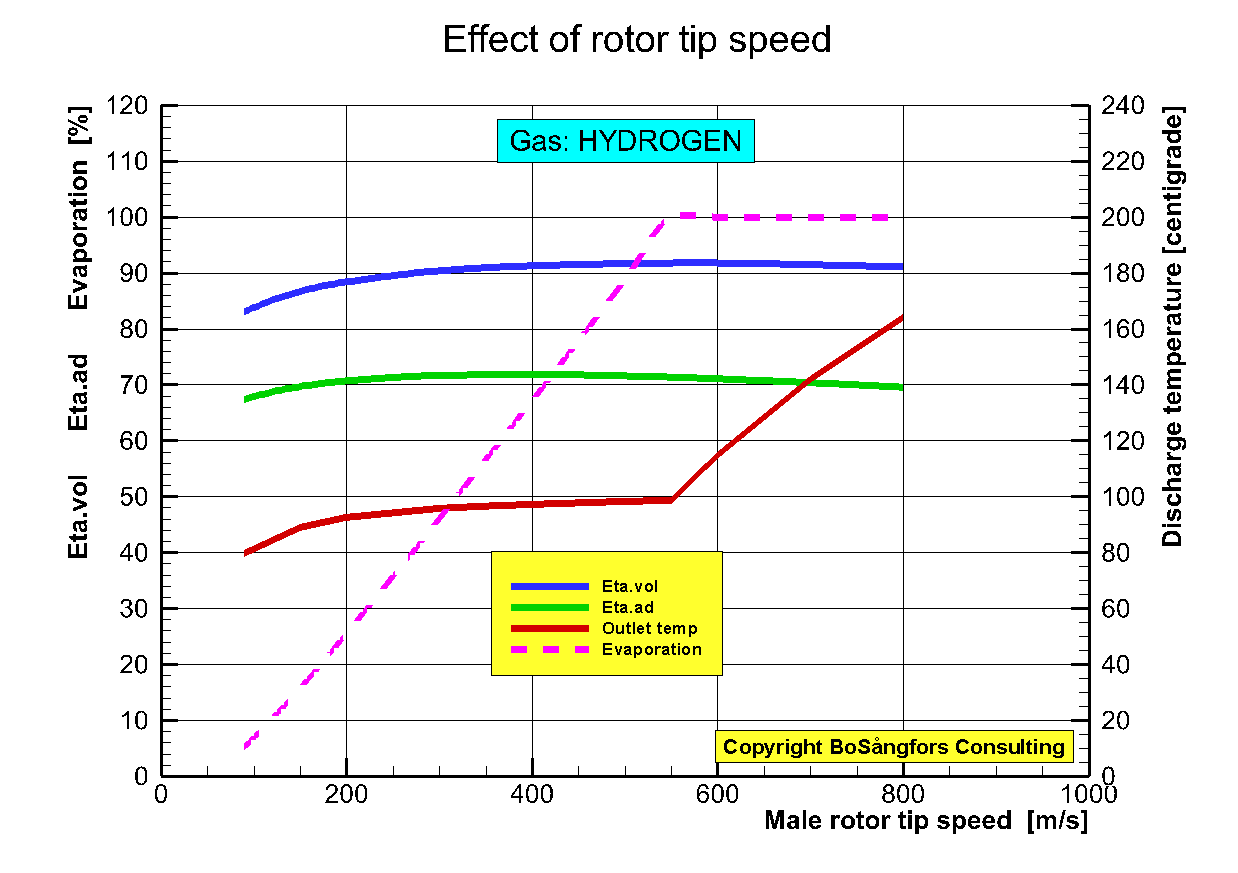

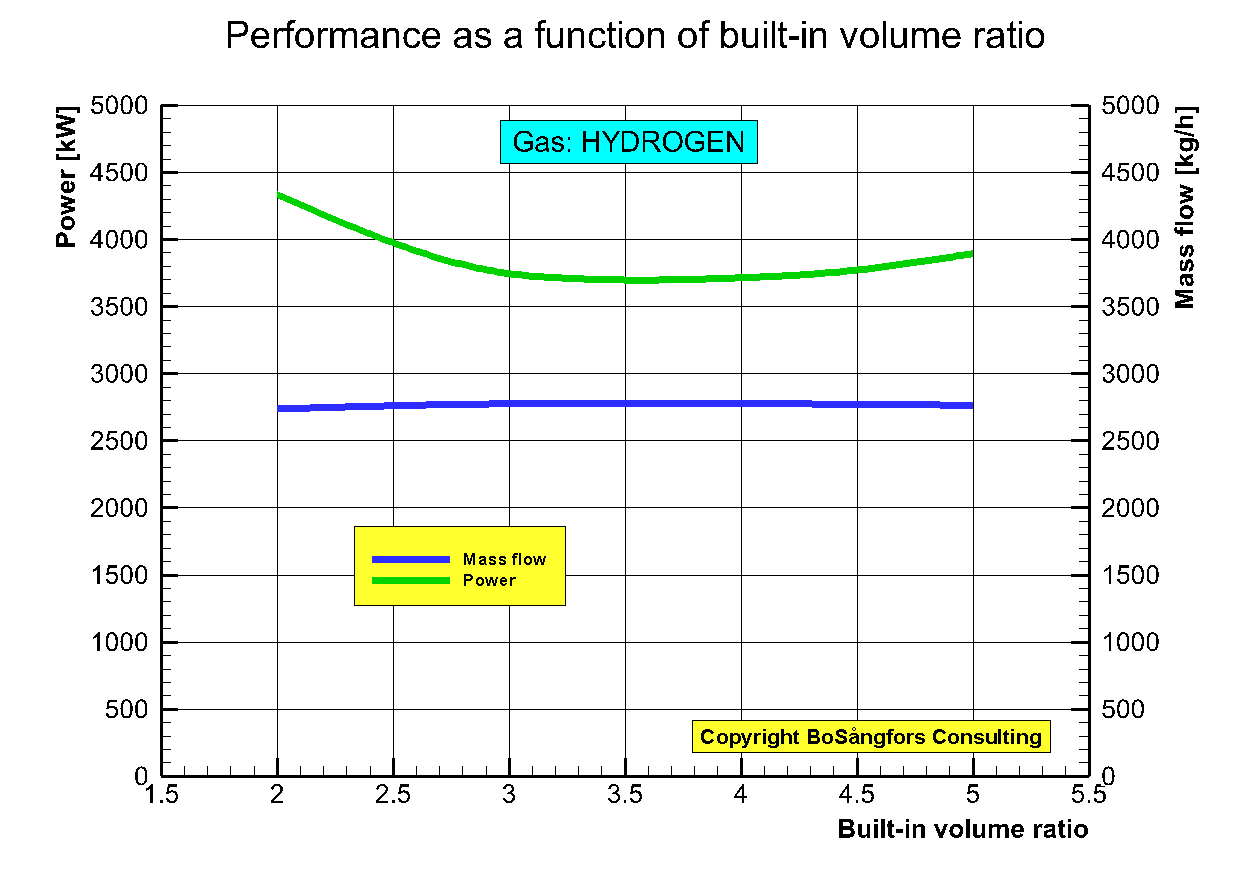

1 to 8

bar Hydrogen Water Injected Screw Compressor Performance.

The calculations are made in accordance with the theory presented in the Purdue paper

Volumetric efficiency = 0.909

Fig.1

Fig.2

Fig.3

Fig.4

===================================================================================================================

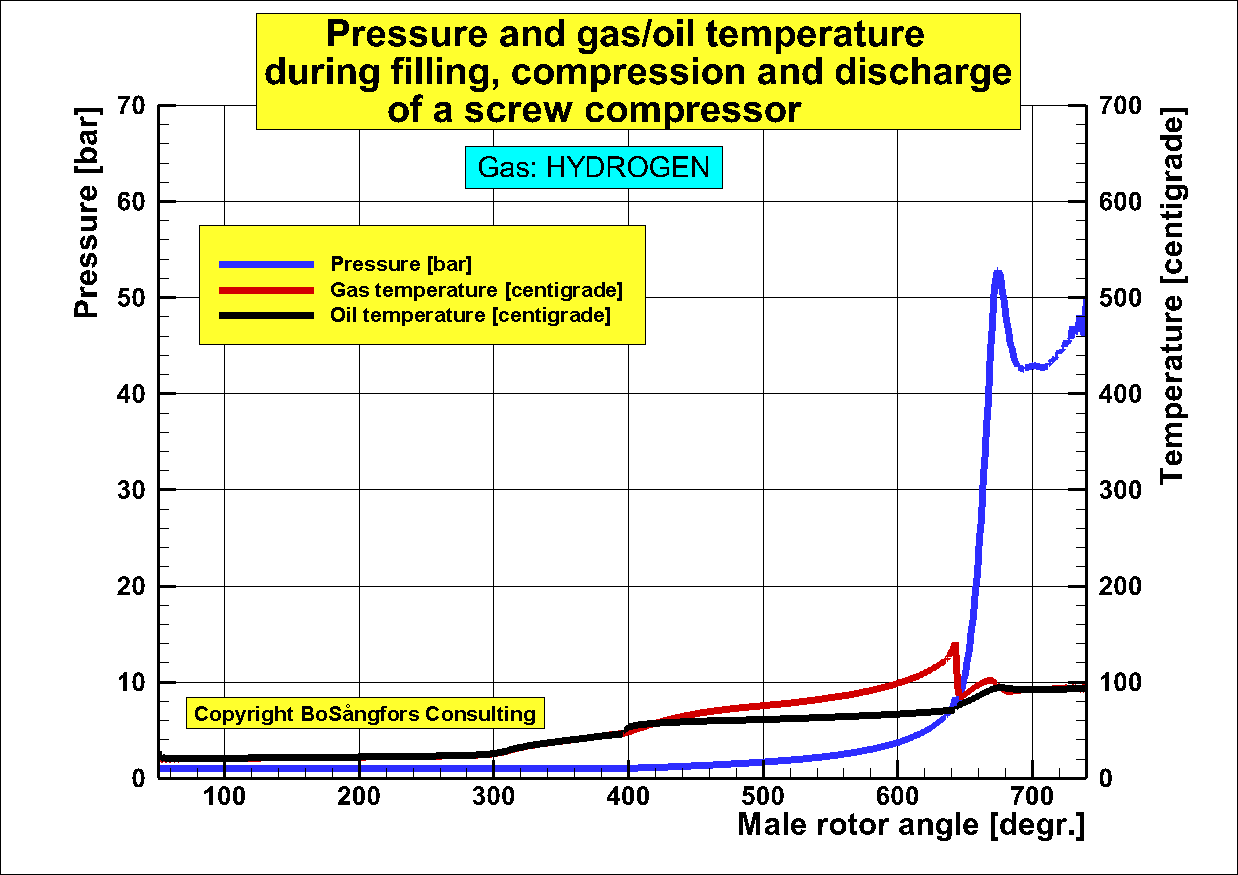

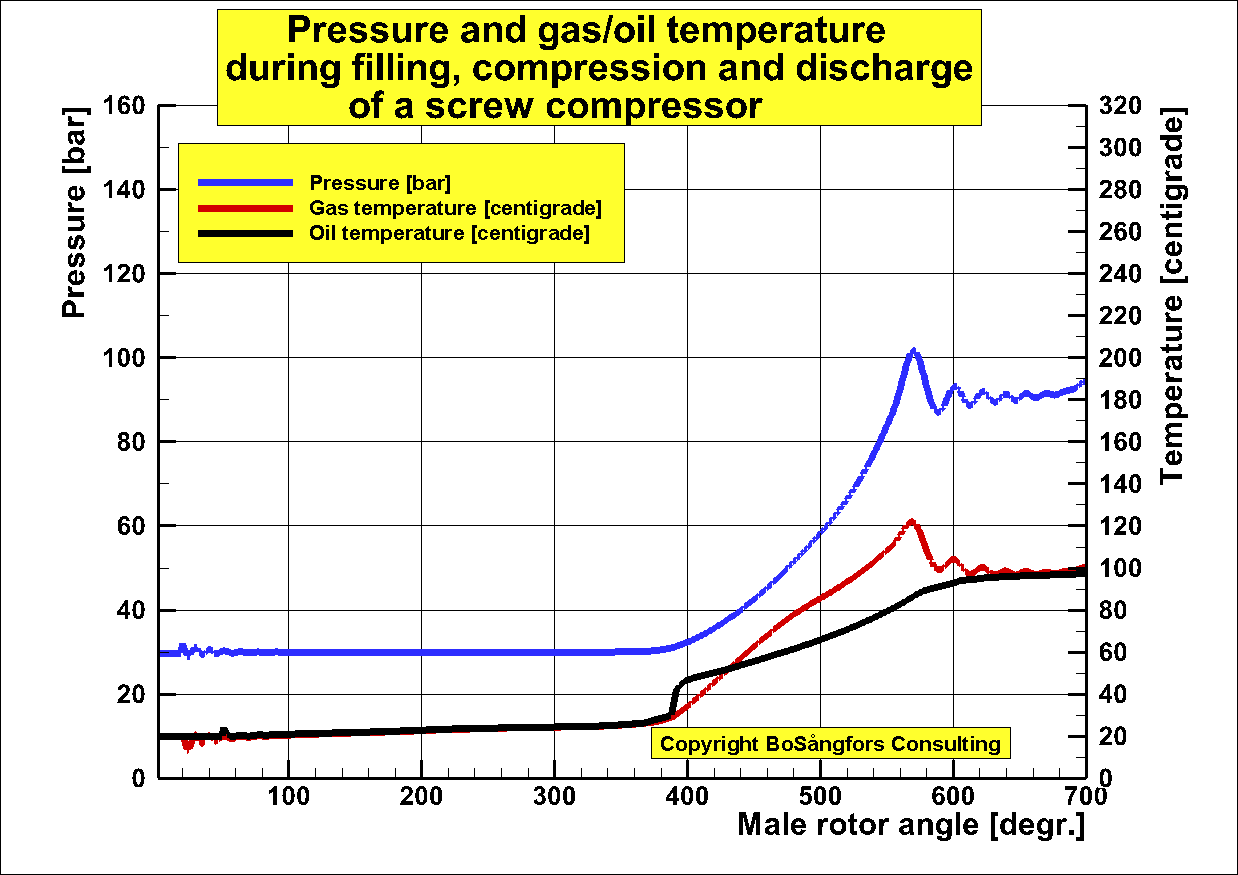

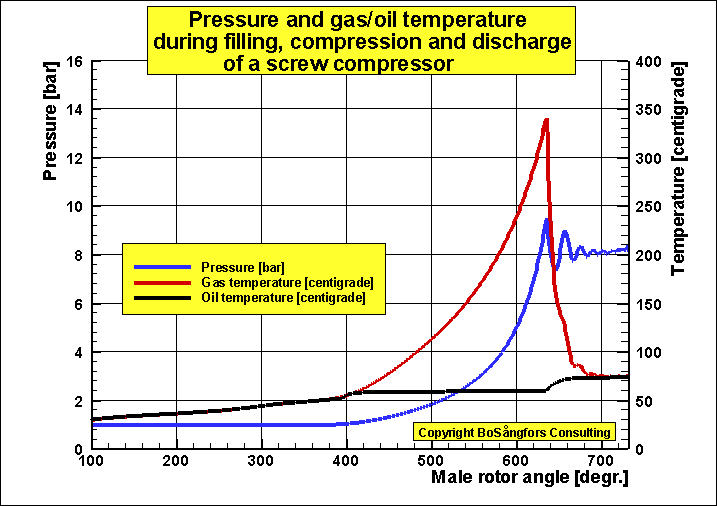

1 to 40 bar Hydrogen

Screw Compressor.

Pressure and gas/oil

temperatures during, filling,

compression and

discharge

Gas=Hydrogen

Built-in volume ratio = 5.0

Rotor diameter = 400 mm

Volumetric efficiency = 0.890

------------------------------------------------------------------------------------------------------------

Fig.1

Fig.2

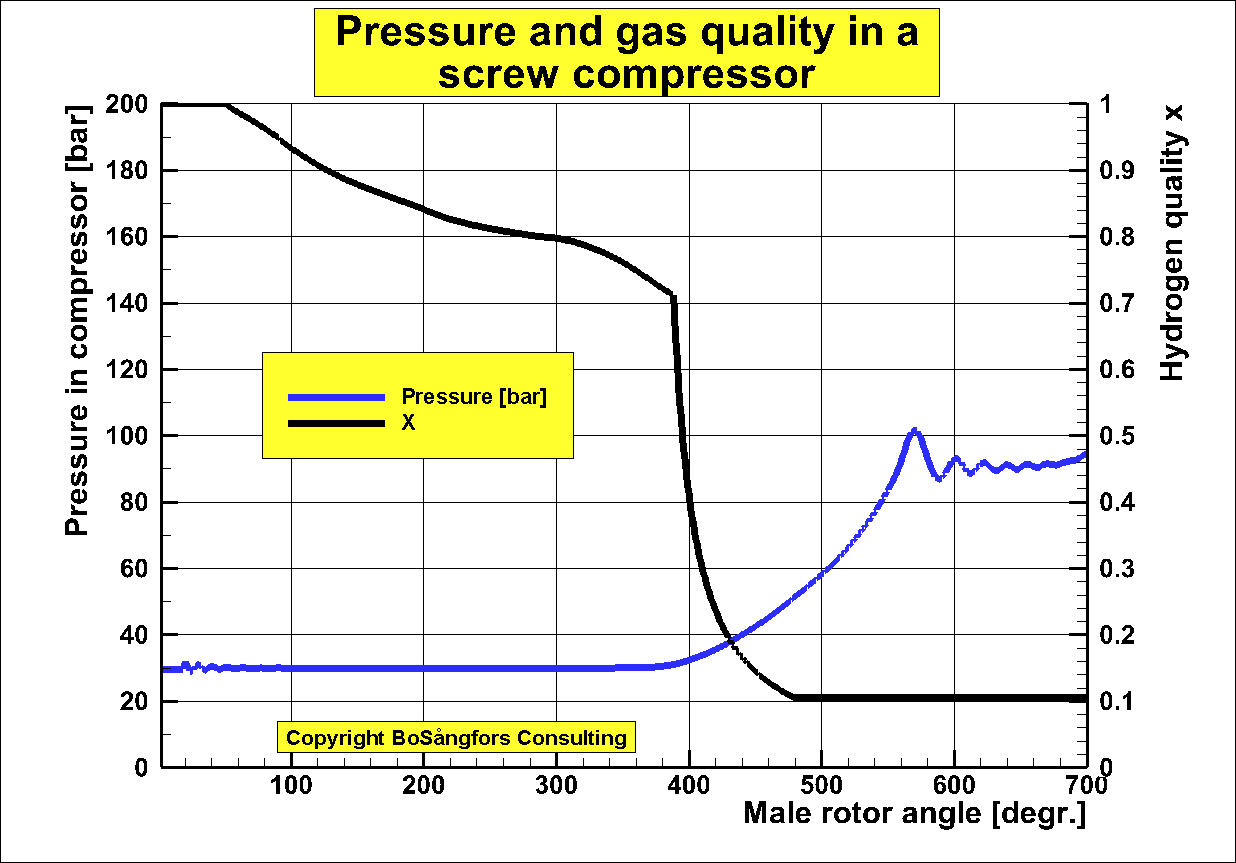

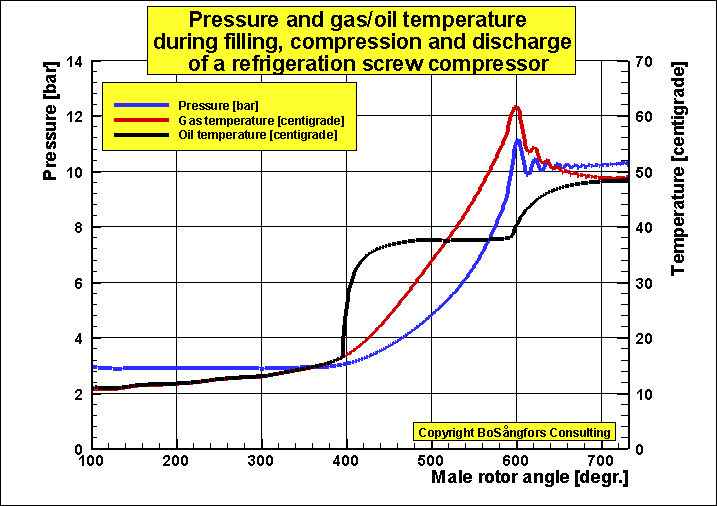

High Pressure Hydrogen

Screw Compressor.

Pressure and gas/oil

temperatures during, filling,

compression and

discharge

Gas=Hydrogen

Built-in volume ratio = 2.19

Rotor diameter = 400 mm

Volumetric efficiency = 0.902

------------------------------------------------------------------------------------------------------------

Fig.1

Fig.2

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

High

performance 2 stage system using twin screw expanders

Stage 1: Steam Screw Expander, Diam.

= 1000 mm

Stage 2: ORC using Ammonia Screw

Expander, Diam. = 484 mm

Tip speeds:

Steam expander 40 to 150 m/s

Ammonia: ORC-expander 20 to 75 m/s

Fig.1 shows the total generated effect as a function of the brine flow in the system.

Fig.1.

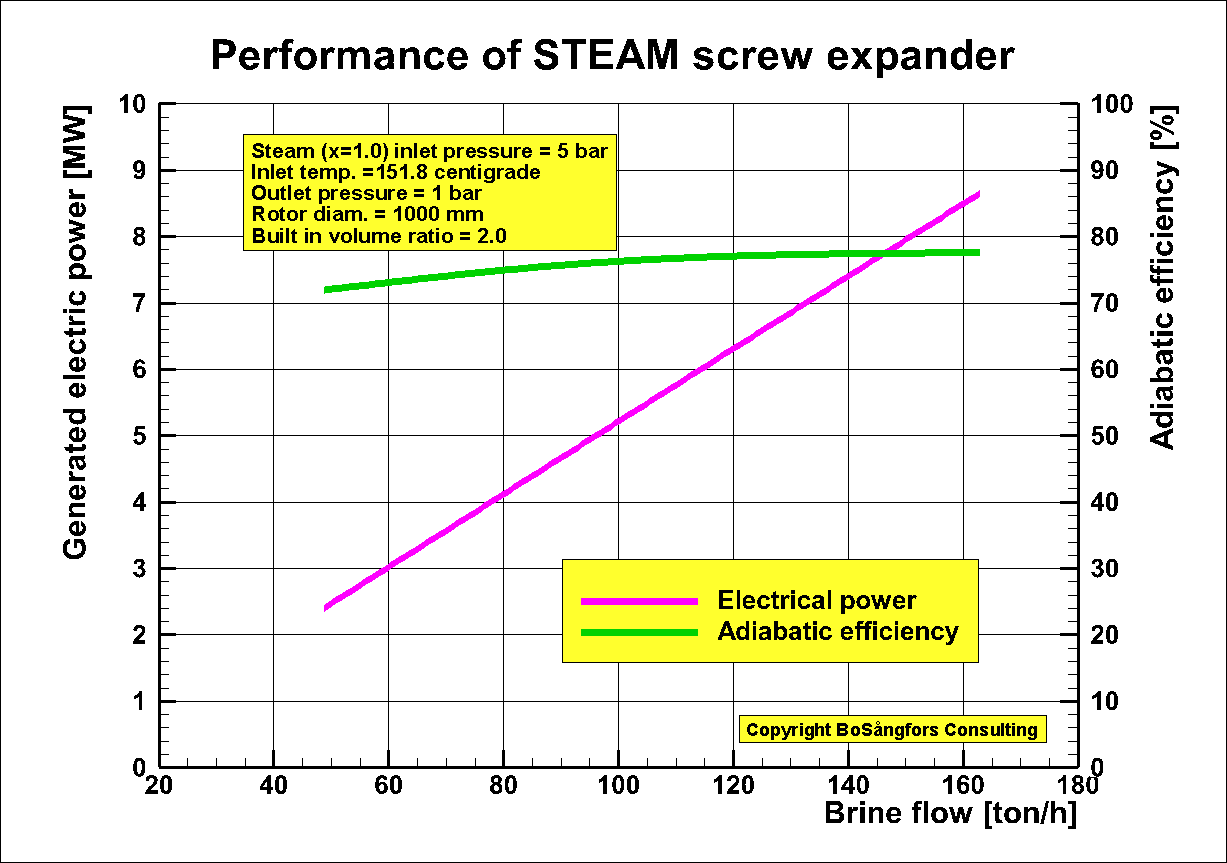

Stage 1: Steam Screw Expander in

above Combined System

Rotor diameter = 1000 mm

Built-in volume ratio = 2.0

Inlet/Outlet pressure = 5/1 bar,

Inlet/Outlet temperature 151.8/100.0 centigrade

Male rotor tip speed = 40 < Vtip < 150 m/s

Generator efficiency = 0.95

Fig.2 shows that the generated effect and the adiabatic efficiency as a function of the brine (steam) flow leaving the steam expander.

Fig. 2

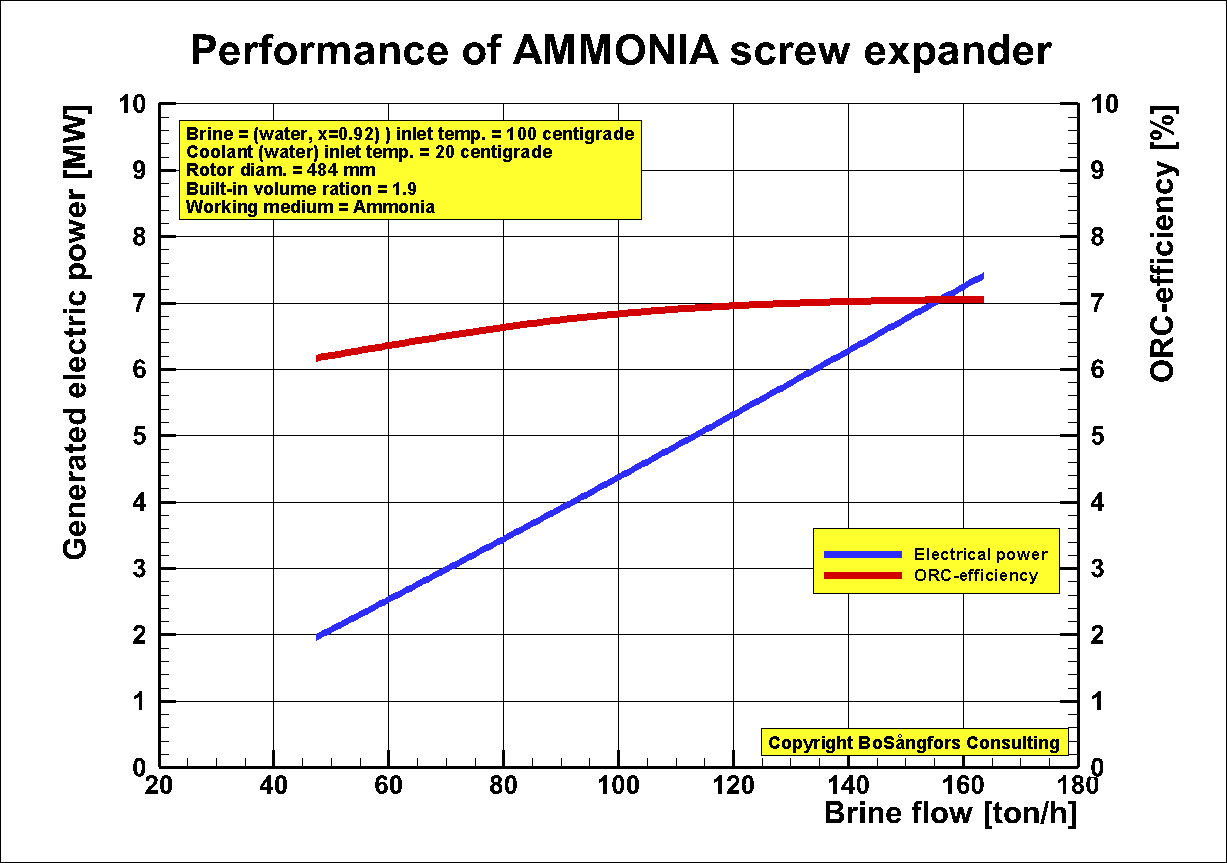

Stage 2: ORC using Screw Expander in

above Combined System

Rotor diameter = 484 mm

Built-in volume ratio = 1.9

Male rotor tip speed = 20 < Vtip < 75 m/s

Brine = Steam of temperature 100

centigrade leaving the steam expander

stage 1

Coolant = Water

Brine temp in = 100

centigrade.

Quality x = 0.92

Coolant temp in = 20 centigrade

Working medium = Ammonia

Ammonia quality x at expander inlet = 1.0

Evaporation temp = 85 centigrade

Condensing temp = 35 centigrade

Temp. efficiency (Evaporator +Preheater) = 90 %

Temp. efficiency Condenser = 90 %

Generator efficiency = 0.95

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Fig 3 shows generated power and ORC-efficiency.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

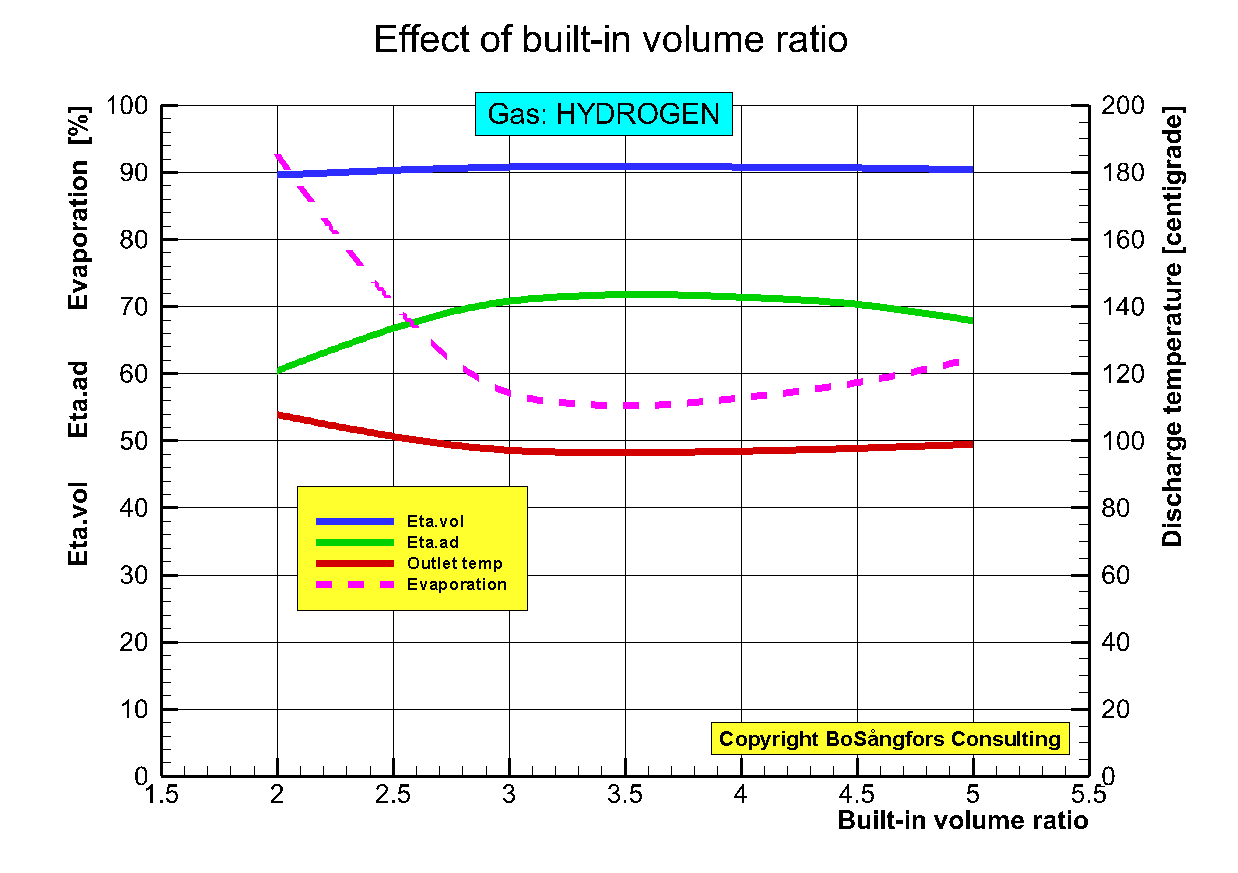

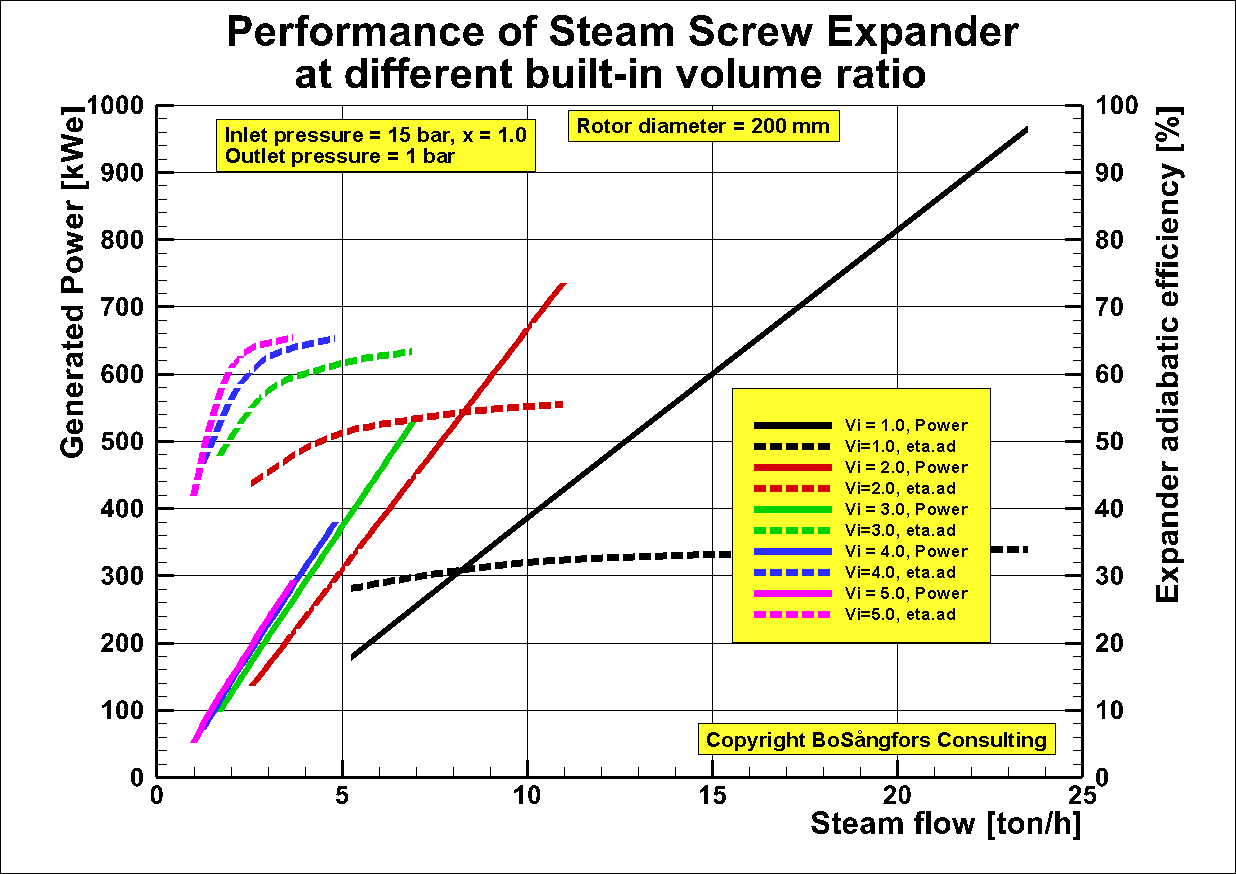

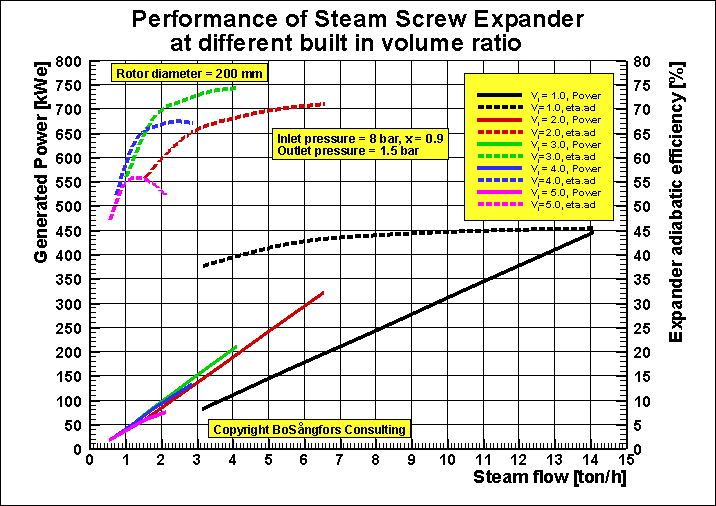

Performance of Steam Screw Expander at different built-in volume

ratio

This graph shows

how the different built-in volume ratio effects the generated

electric power and the screw expander adiabatic efficiency.

Generator

efficiency = 0.95

The rotor tip

speeds are from 20 m/s up to 110 m/s.

As can be seen

low built-in volume ratio leads to high power output but to low

adiabatic efficiency.

The graph below is for inlet pressure 8 bar and outlet pressure 1.5 bar.

Note: The steam quality x=0.90

Generator efficiency = 0.95

As can be seen in this example there is a built-in volume ratio point that gives the best adiabatic efficiency.

Another point of

interest is that Vi=3.0 and Vi=4.0 are quite close in

performance.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

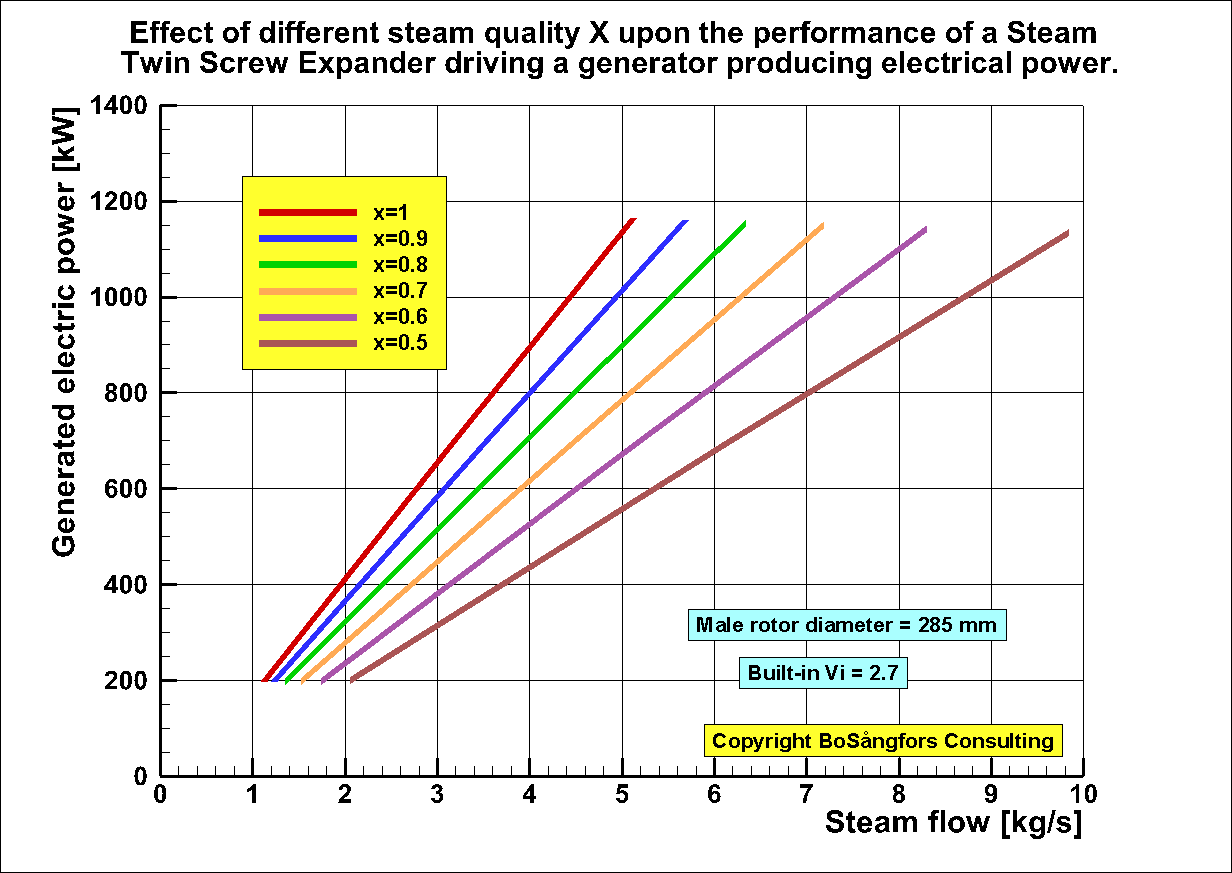

Effect of different steam quality X upon the

performance of a SteamTwin Screw Expander driving a generator producing

electrical power.

Male

rotor diameter = 285 mm.

Outlet pressure = 2.7 bar

The presented data set shows the generated electrical power as a function of the

steam flow at various steam quality x.

Generated electrical power as a function of steam flow.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

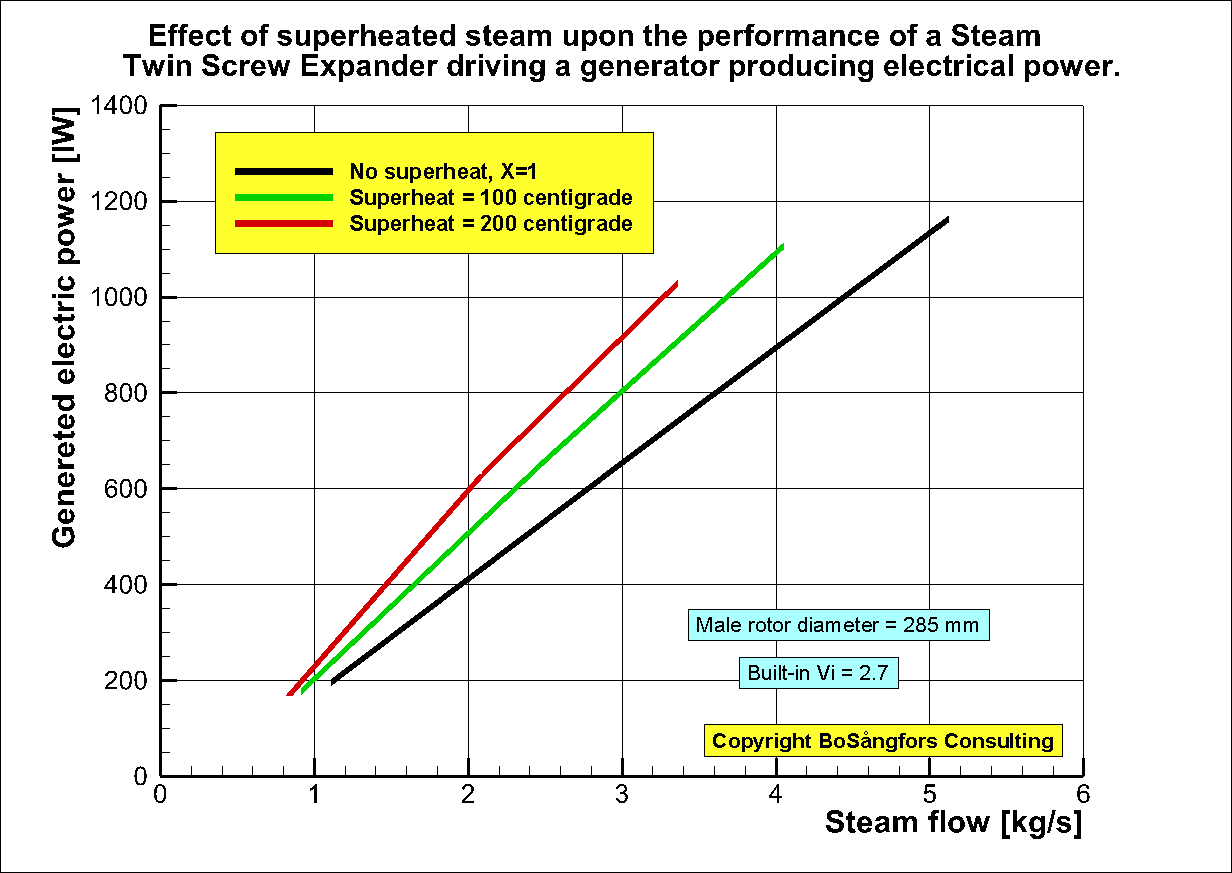

Effect of superheated

steam upon the performance of a Steam

Twin Screw Expander driving a generator

producing electrical power.

Male

rotor diameter = 285 mm.

Outlet pressure = 2.7 bar

The presented data set shows the generated electrical power as a function of the

steam flow at various steam superheat.

Generated electrical power as a function of steam flow.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

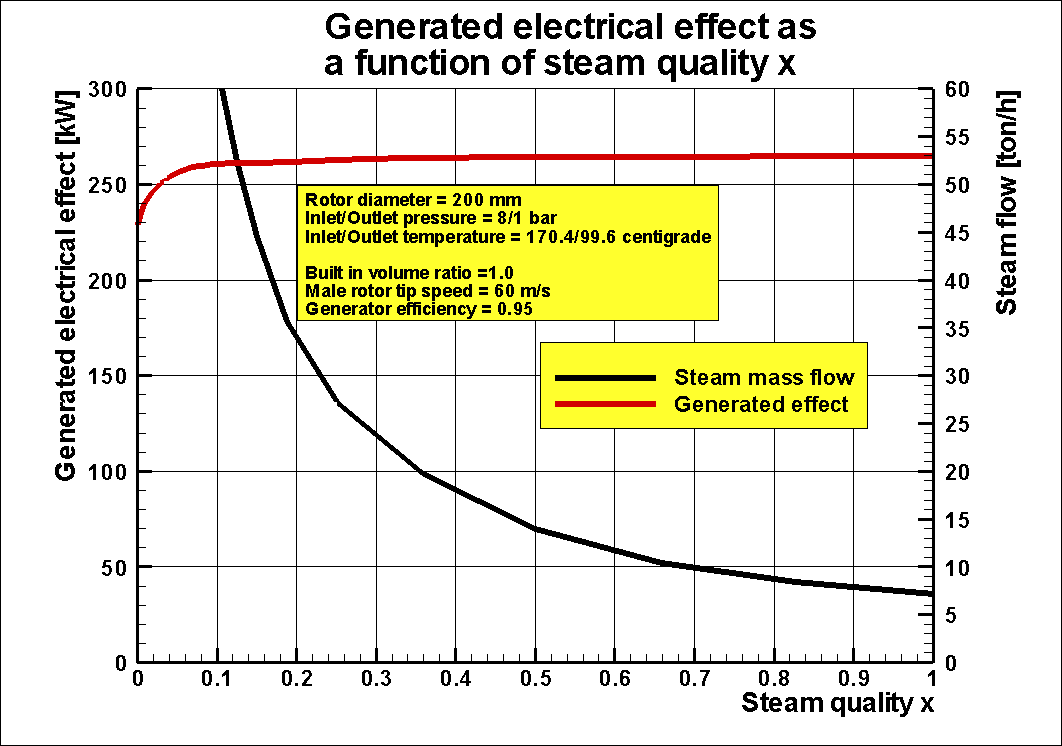

As can be seen it is very important to have a good steam quality. I.e. = 1.

Therefore slight superheating is recommended.

For instance if X=0.5 instead of 1, the steam consumption will increase with a factor 2. I.e.the machine acts as if 50% of the flow is by-passed.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

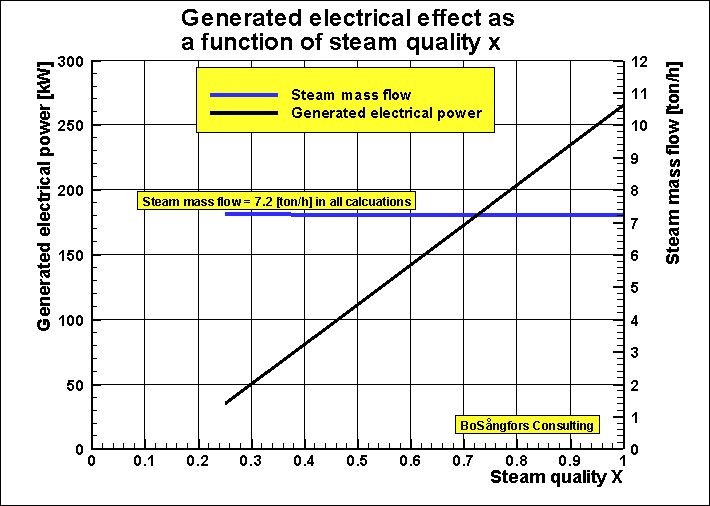

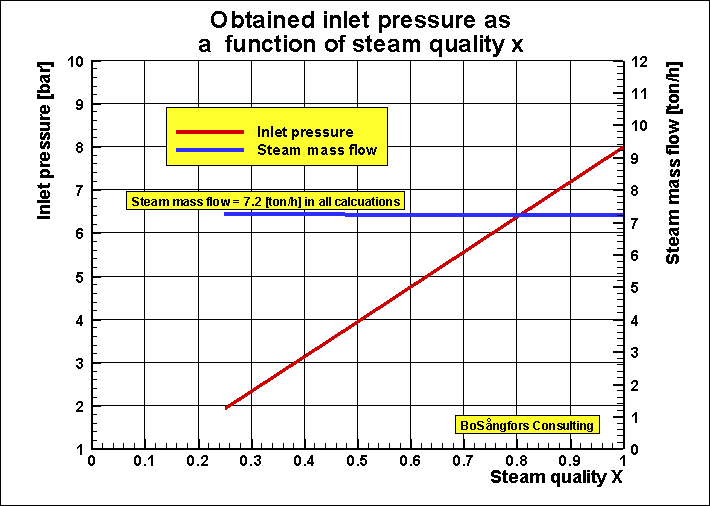

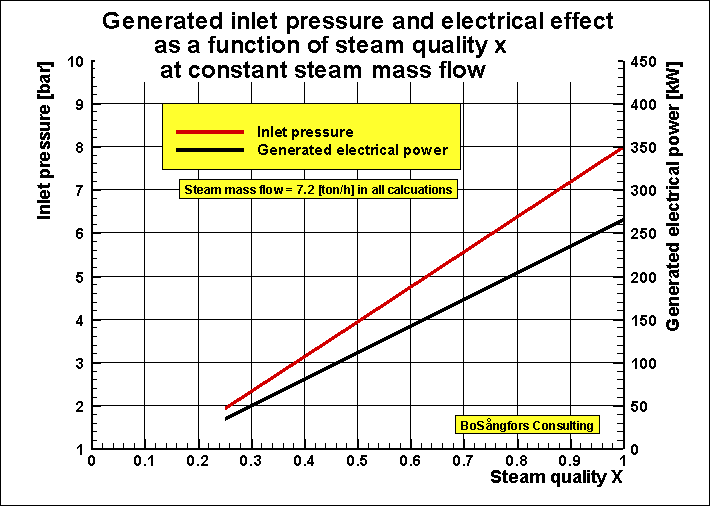

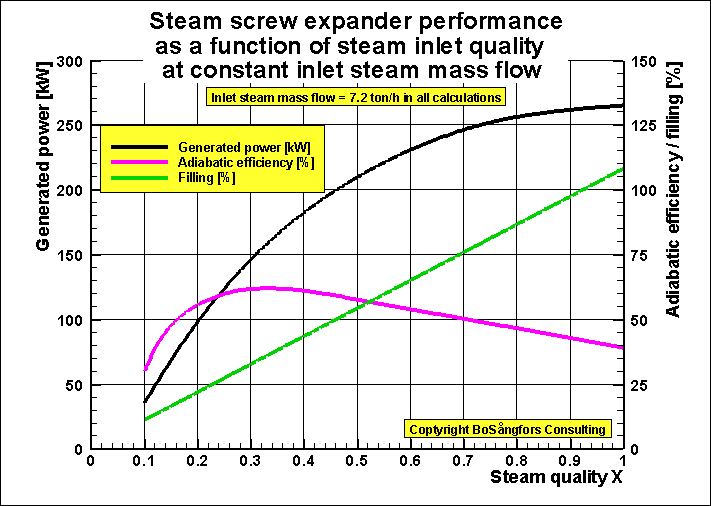

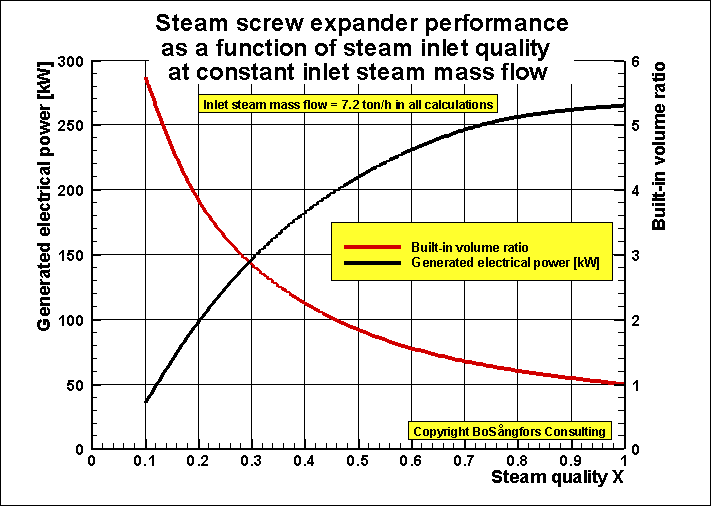

Effect of inlet steam

quality X if the inlet steam mass flow is constant.

This is an

addition to the data file Importance of having good steam quality x at the

inlet of a Steam Screw Expander generating electric power earlier uploaded on

Research Gate

In these calculations

the steam mass flow is kept constant by changing the inlet pressure and

temperature. As can be seen the generated power as well as the inlet pressure

decreases with decreasing inlet steam quality.

Other

data are:

Rotor

diameter = 200 mm

Inlet/Outlet pressure = 8/1 bar at steam quality = 1.0

Inlet/Outlet temperature 170.4/99.6 centigrade at steam quality = 1.0

Inlet steam mass flow = 7.2 ton/h in all

calculations.

Built in volume ratio =1.0.

By

having this value effects from flashing or condensation are outside the control

volume. I.e. they can be neglected

Male rotor tip speed = 60 m/s

Generator efficiency = 0.95

Fig.1 shows that the generated effect decreases with decreasing steam quality.

Fig. 1

This is

due to the decrease in inlet pressure, See fig.2.

Fig. 2

Fig. 3

shows the decrease of inlet pressure and generated electric power.

As is

obvious from these calculations the inlet quality is an important parameter,

Fig. 3

ญญญญญญญญญญญญญญญญญญญ-------------------------------------------------------------------ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

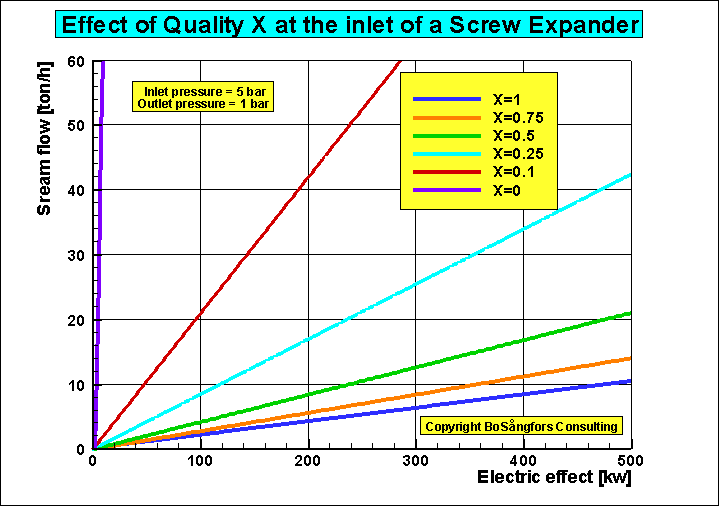

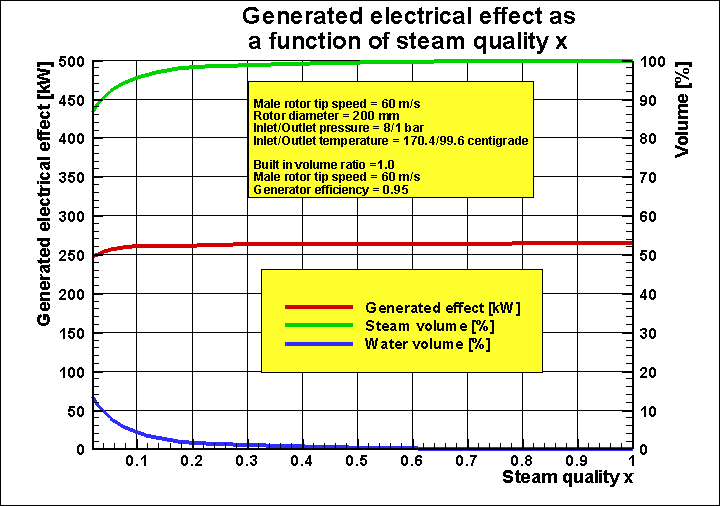

Importance of having good steam quality x at the inlet of a Steam Screw Expander generating electric power.

The water volume is very small.

------------------

Fig. 1

This looks very nice, but a look at fig.2 below shows that the steam consumption

is very dependent of the steam quality x.

For example if you decrease the steam quality from 1 to 0.5 the steam mass flow

increases twice.

ญญญญญญญญญญญญญญญญญญญ-------------------------------------------------------------------ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

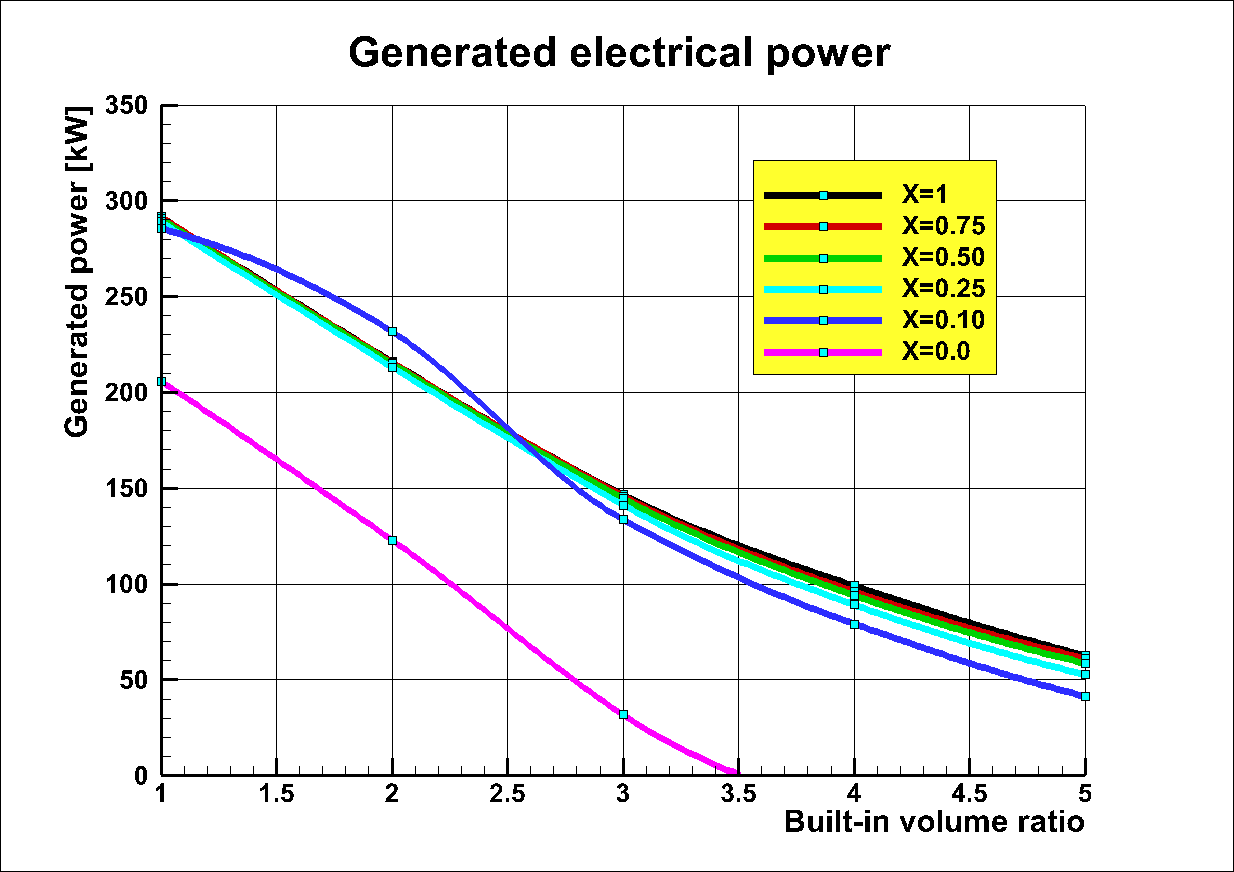

Effect of built-in

volume ratio at different steam quality X upon the performance

of aTwin Screw Steam Expander driving a

generator producing electrical power.

In order to give more information about the effects of various built-in

ratio at different steam quality X, when using a screw expander for

generating electrical power these calculations are presented.

The expander is a dry twin screw expander with synchronizing bearings

Profile = 4+6-combination

Male rotor diameter = 285 mm

Female rotor diameter = 285 mm.

Male rotor tip velocity = 60 m/s

Inlet pressure = 5 bar.

Inlet temperature = 151.85

centigrade

Outlet pressure = 1bar

The quality x noted in the graphs are values at the screw expander inlet.

Generator efficiency = 95 %

Calculation

results:

The presented data sets below show the following:

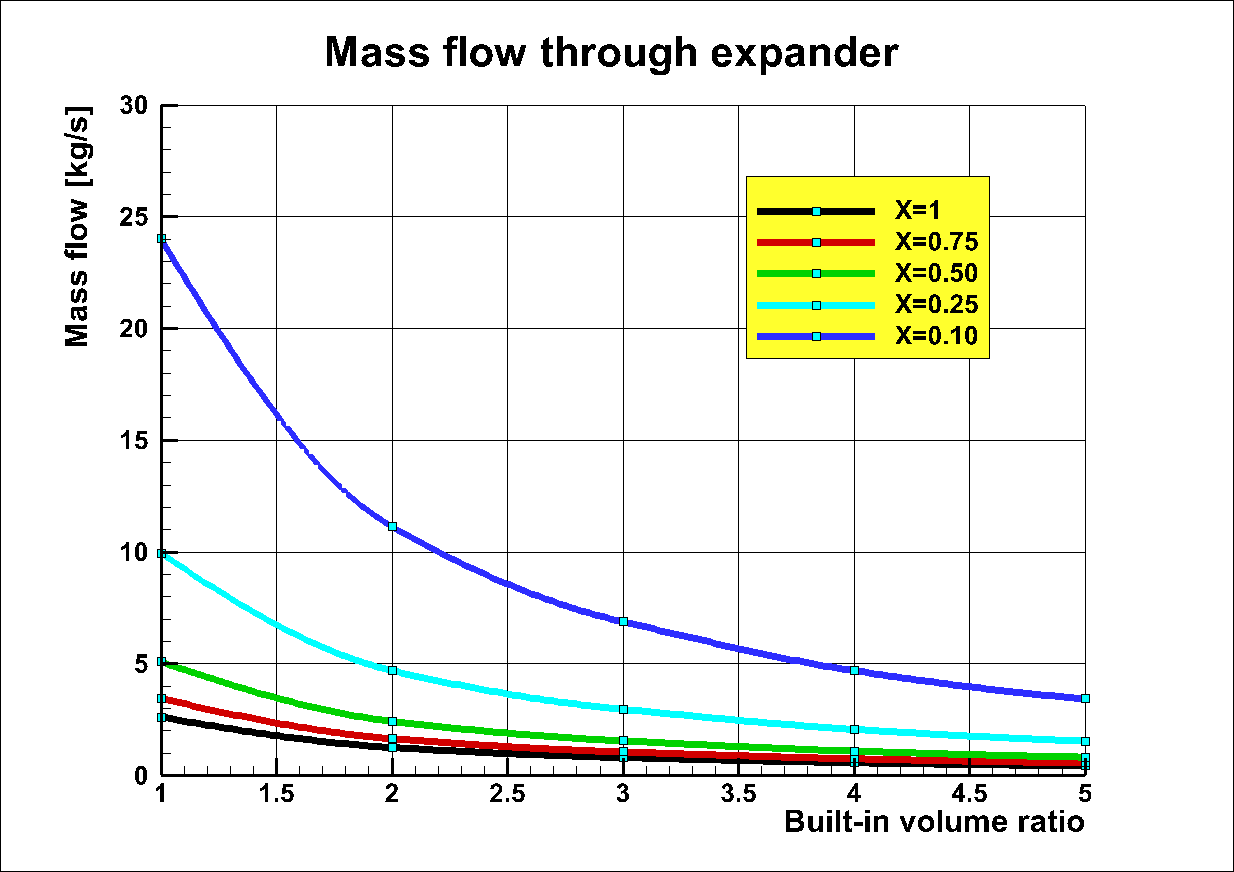

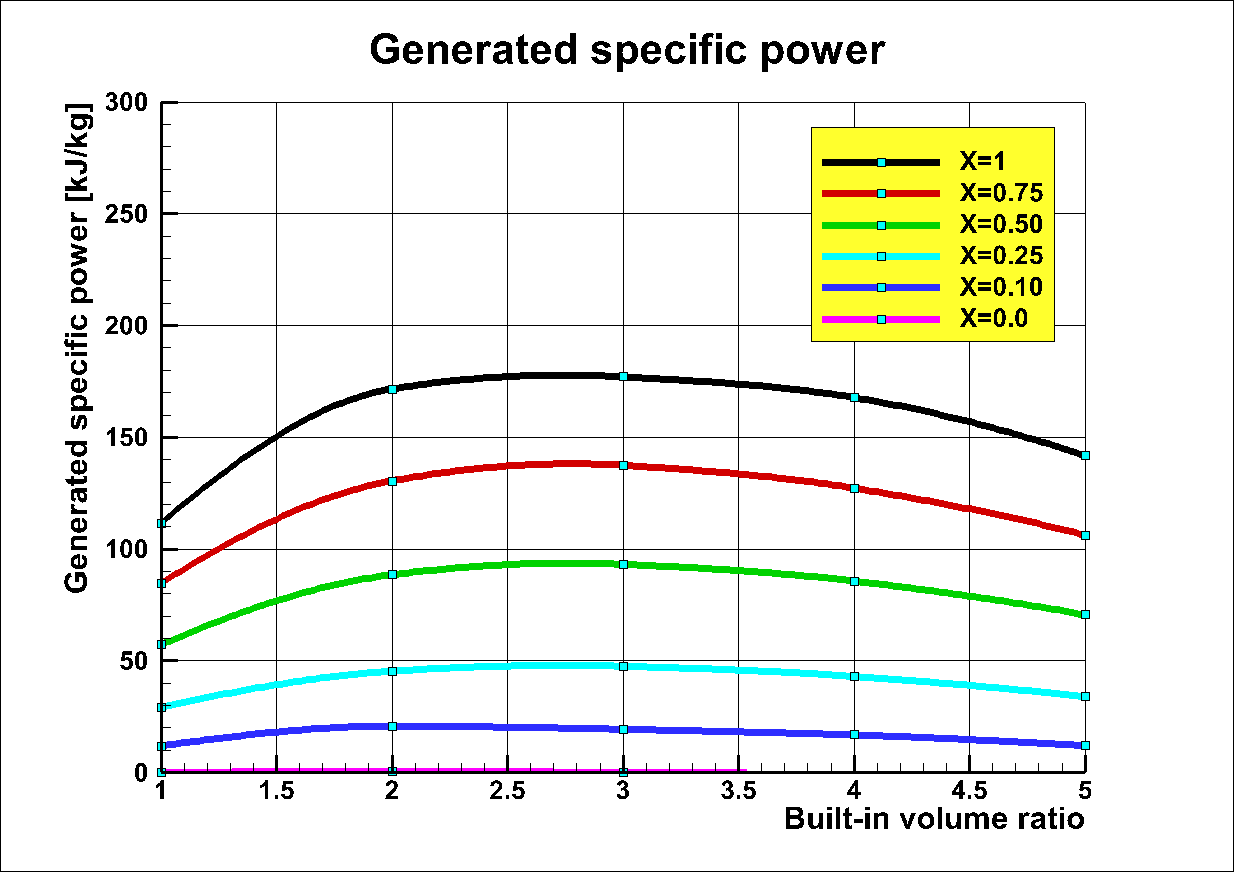

Fig.1 shows the generated electrical power as a function of built-in

volume ratio at various steam quality X.

Fig.2 shows the mass flow through the expander.

Fig.3 shows the generated specific power.

Fig. 1. Generated electrical power as a function of built-in volume ratio.

As can be seen the generated power is

about the same for quality 0.10 < x < 1.

Notice that at x=0.0 the generated power

is drastically decreased due to high inlet

pressure drop caused by the water quality x=0.

Fig. 2. Mass flow through

expander as a function of built-in volume ratio.

As is obvious the mass flow through the screw expander increases with decreasing quality x.

Fig. 3. Generated

specific power as a function of built-in volume ratio.

The generated specific power is

calculated: (generated power [kW])/ (mass flow through expander [kg/s]).

Conclusion

It is quite obvious that it is important to have a high quality x.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

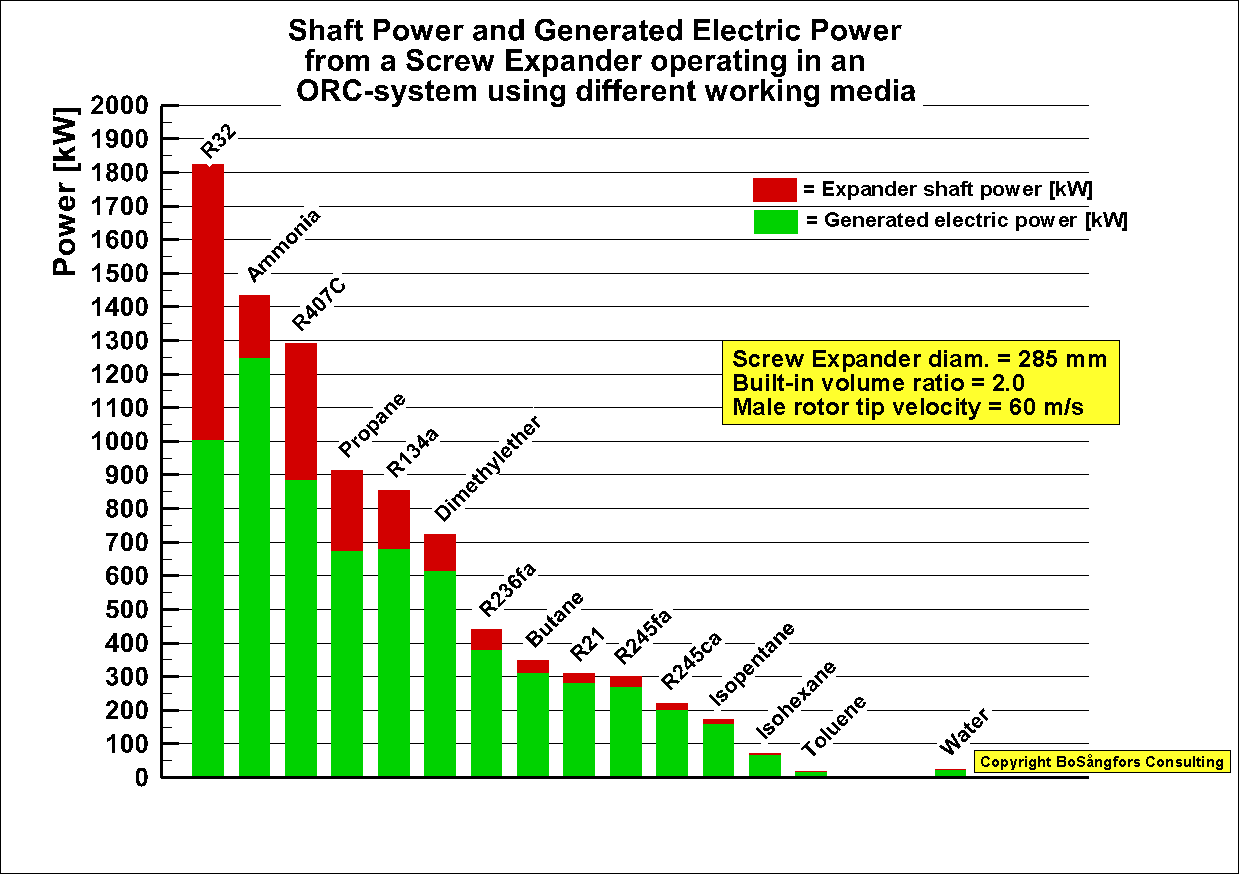

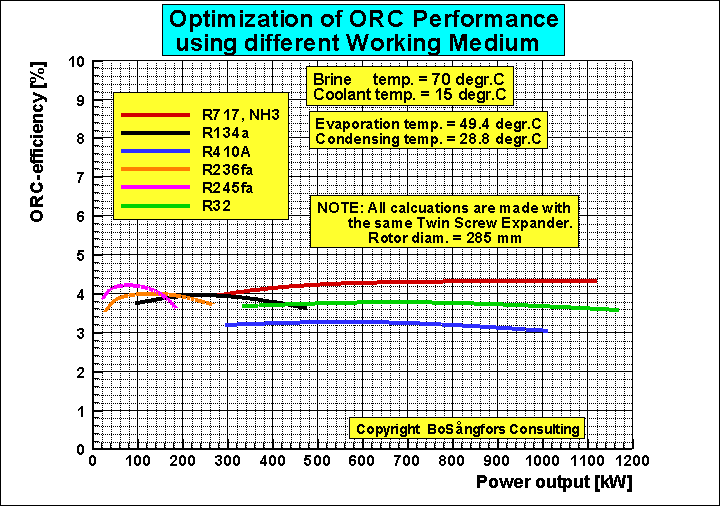

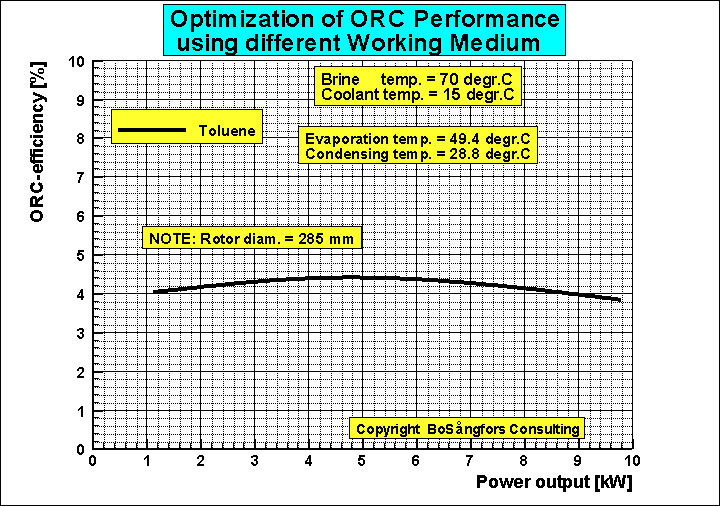

ORC-system

Shaft Power and Generated Electric Power

from a Screw Expander operating in an

ORC-system using different working media

In order to give some feeling about the effects of different working media on the performance of a twin screw expander with the diameter 285 mm these calculations are presented.

As is shown the choice of working media is very important and determines the size of the screw expander.--------

The expander is a dry screw expander with synchronizing bearings.Rotor diameter = 285 mm

Brine = Water

Coolant = Water

Brine temp = 100 centigrade

All calculations are at built-in volume ratio = 2.0 and male rotor tip speed = 60.0 m/s

Coolant pump losses are included.

Temperature efficiency Condenser = 90 %

The main reason for this is that the media pumping power is higher for R32 than for Ammonia.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

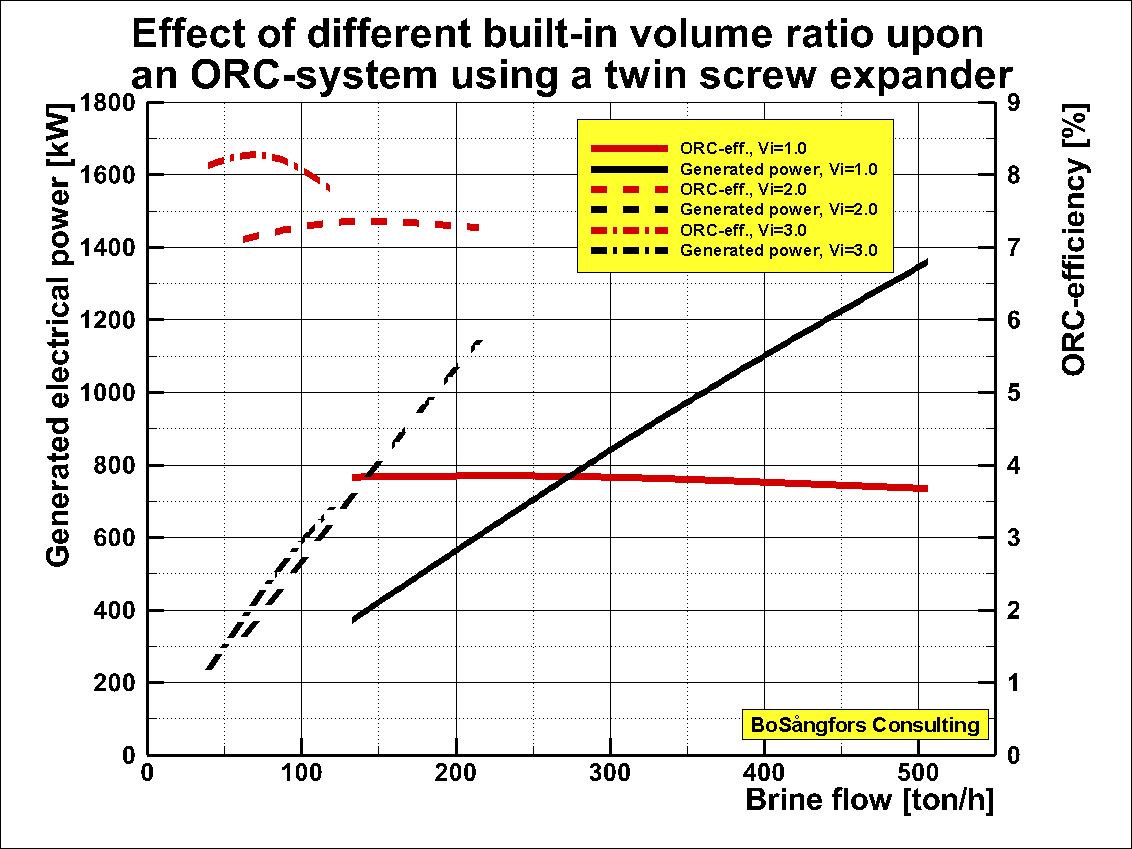

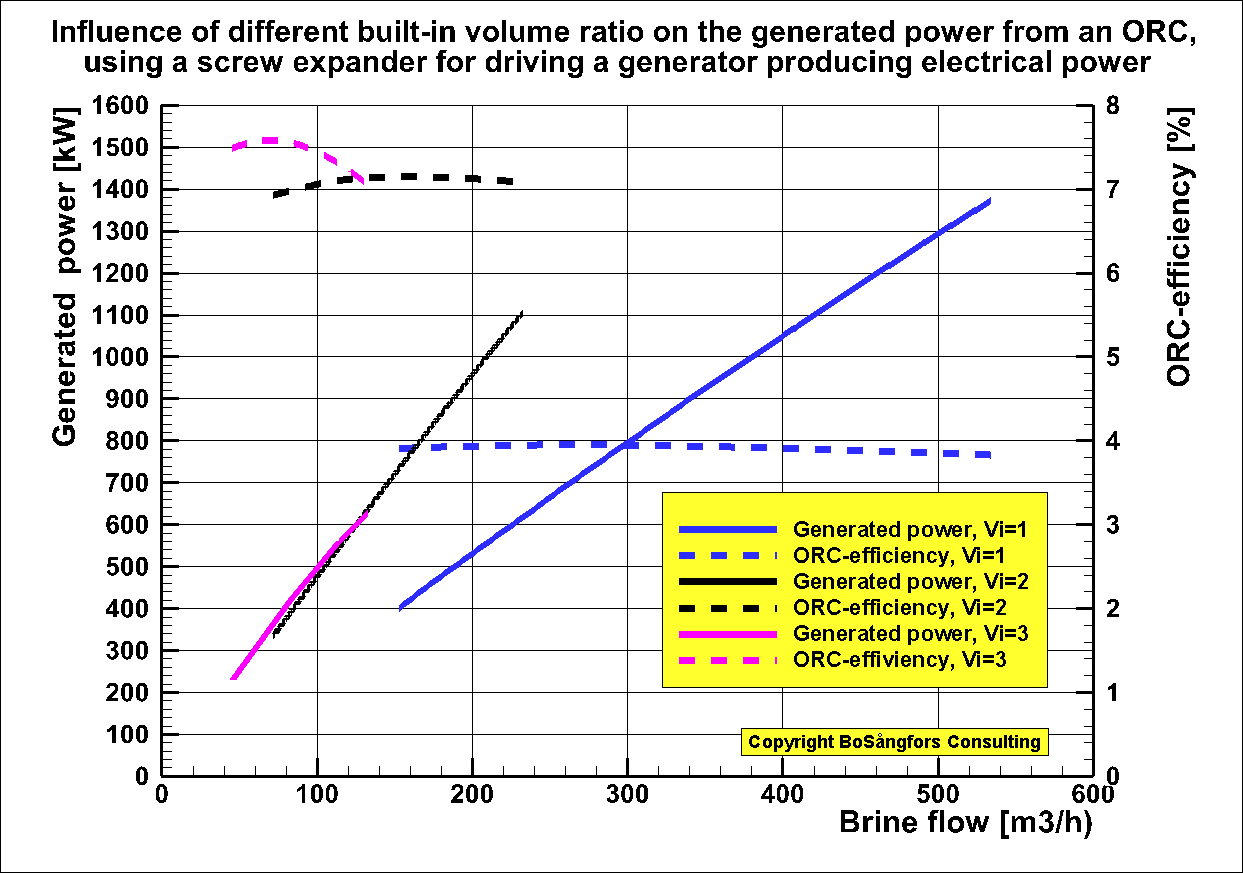

Effect of different built-in volume ratio

upon the performance of an ORC-system,

which uses a helical screw expander for

driving a generator producing electrical power.

In order to give more information about the effects of

various built-in volume ratio Vi, when using a screw expander in an

ORC-system these calculations are presented.

The

presented graph presents the performance as a function of the brine flow.

The expander

is a dry screw expander with synchronizing bearings

Rotor

diameter = 285 mm

Built in volume ratio = 3 cases, namely 1, 2, 3.

The optimized built-in volume ratio in this case = 3

Male rotor tip speed is from 30 m/s up to 120 m/s

Working media = R236fa

Quality x =

1.0 at the screw expander inlet.

Brine =

Water

Coolant =

Water

Brine temp =

100 centigrade

Coolant temp

= 20 centigrade

Evaporation temp. = 90 centigrade

Condensing temp. = 30 centigrade

Pump losses

in ORC system are included.

Brine pump

losses are not included.

Coolant pump losses are included.

Fluid pump efficiency = 0.7

Temp. efficiency (preheater+evaporator) = 0.9

Temp. efficiency condensor = 0.9

Generator efficiency = 0.95

Calculation results:

As can be

seen from the graph the built-in volume ratio = 1 gives the highest production

of power, but the ORC-efficiency is not so high.

At Vi=3 the ORC-efficiency is highest at brine flow = 72 ton/hour

ORC-efficiency = 8.3 %

Generated power = 433 kW

Performance as a function of brine flow

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

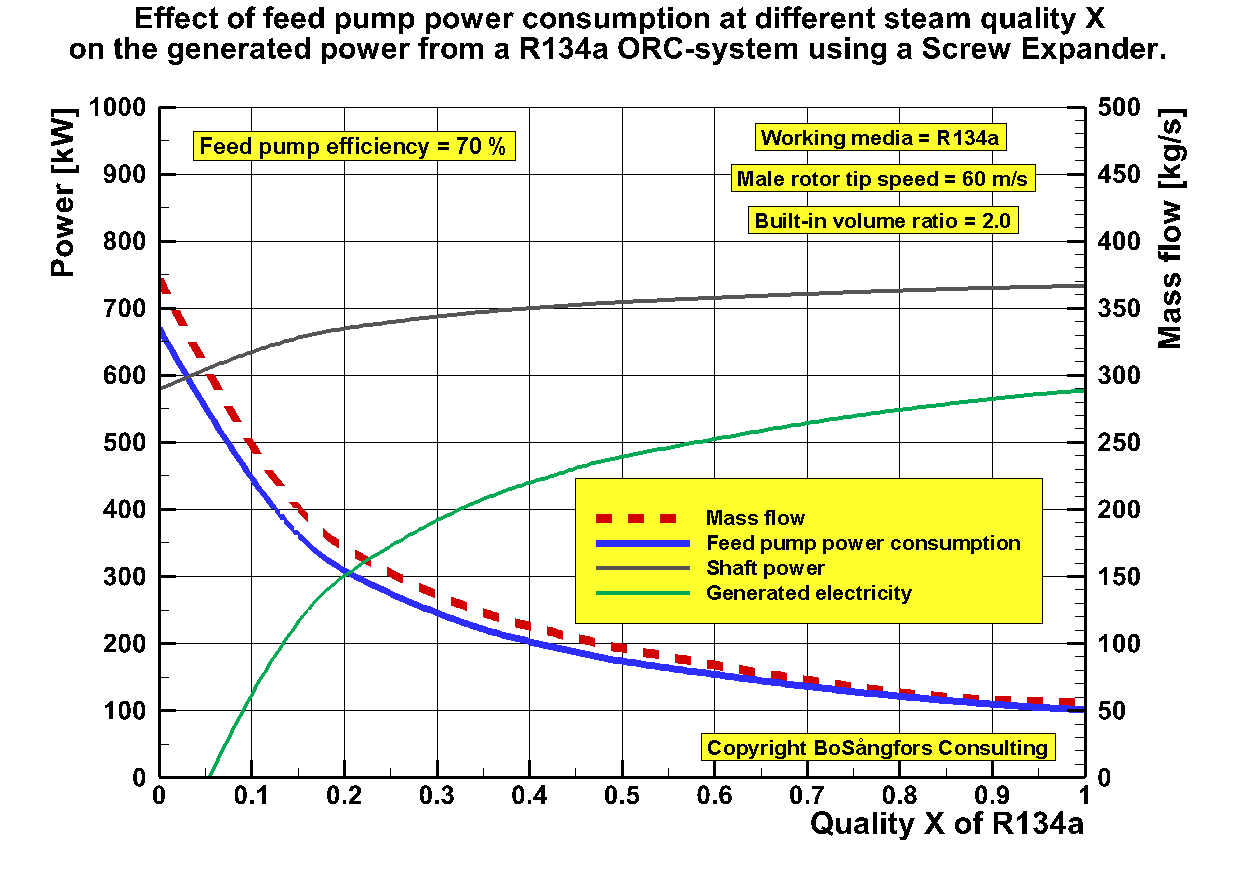

Effect of feed pump

power consumption at different steam quality X on the generated power from a

R134a ORC-system using a Twin Screw Expander.

-----------------

Brine = Water

Coolant = Water

Working medium =R134a, 0.0 < x

<1.0 at the expander inlet

Built-in volume ratio =2.0

NOTE: This built-in volume ratio is then used in all calculations

Rotor diameter = 285 mm

Male rotor tip speed = 60 m/s

Brine temp in = 100 centigrade

Coolant temp in = 20 centigrade

Evaporation temp = (11*Brine temp + 5*Coolant temp)/16 = 95.625

centigrade

Evaporation pressure = 23.641 bar

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 = 40.625 centigrade

Condensing pressure = 8.8698 bar

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

---------------------------------------------------------------------------------------------------------------------------------

Fig 1 shows the

mass flow, feed pump consumption, shaft power and the generated electricity.

As you can see

decreasing quality X increases the mass flow, which also leads to increased feed

pump power consumption.

At steam quality

close to zero the losses caused by the feed pump are higher than the generated

shaft power.

As is obvious it is important to have a good quality x at the expander inlet.

Fig.1

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

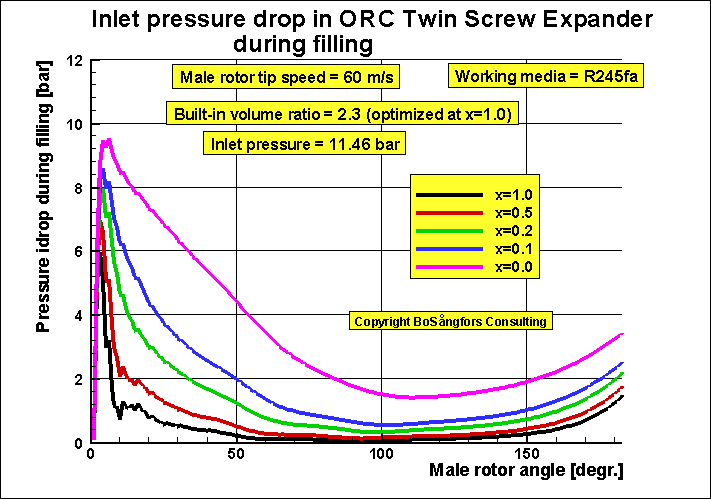

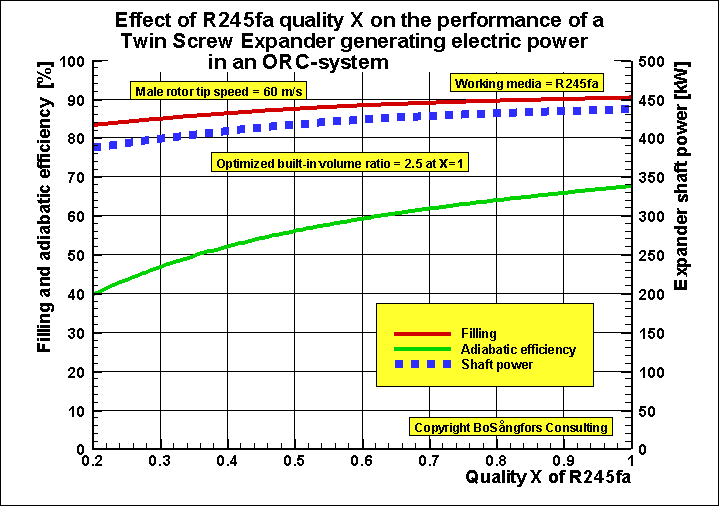

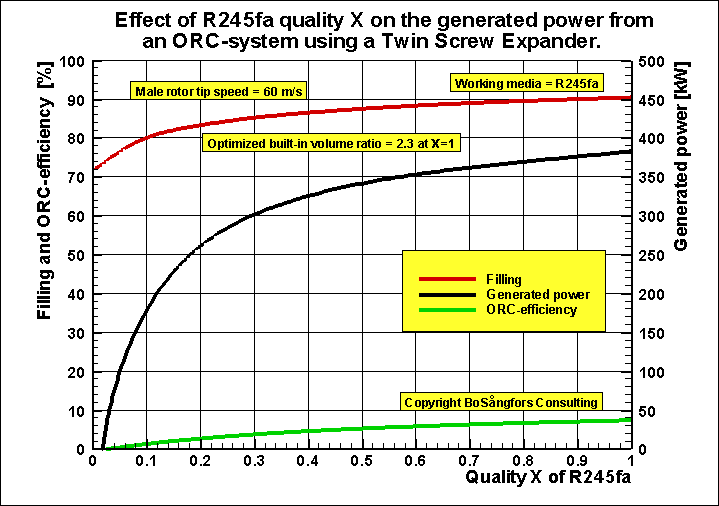

Screw

Expander Inlet Pressure Drop and its Effect on

Performance as a function of R245fa inlet quality X

Input data:

Brine = Water

Coolant = Water

Built-in volume ratio =2.5, Optimized at X=1.0

NOTE: This built-in volume ratio is then used in all calculations

Rotor diameter = 285 mm

Male rotor tip speed = 60 m/s

Brine temp in = 120 centigrade

Coolant temp in = 20 centigrade

Evaporation pressure = 11.46 bar

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 = 40.625 centigrade

Condensing pressure = 2.5567 bar

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

---------------------------------------------------------------------------------------------------------------------------------

As is obvious the pressure drop is high at the opening and the closing of the inlet port due to the small areas.

Fig 1

Fig 2 shows the shaft power as well as the filling and the adiabatic efficiency.As you can see all these parameters decrease when the quality X at the expander inlet decreases.

As is obvious it is important to have a good quality x at the expander inlet.

As you can see all these parameters decrease when the quality X at the expander inlet decreases.

As is obvious it is important to have a good quality x at the expander inlet.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

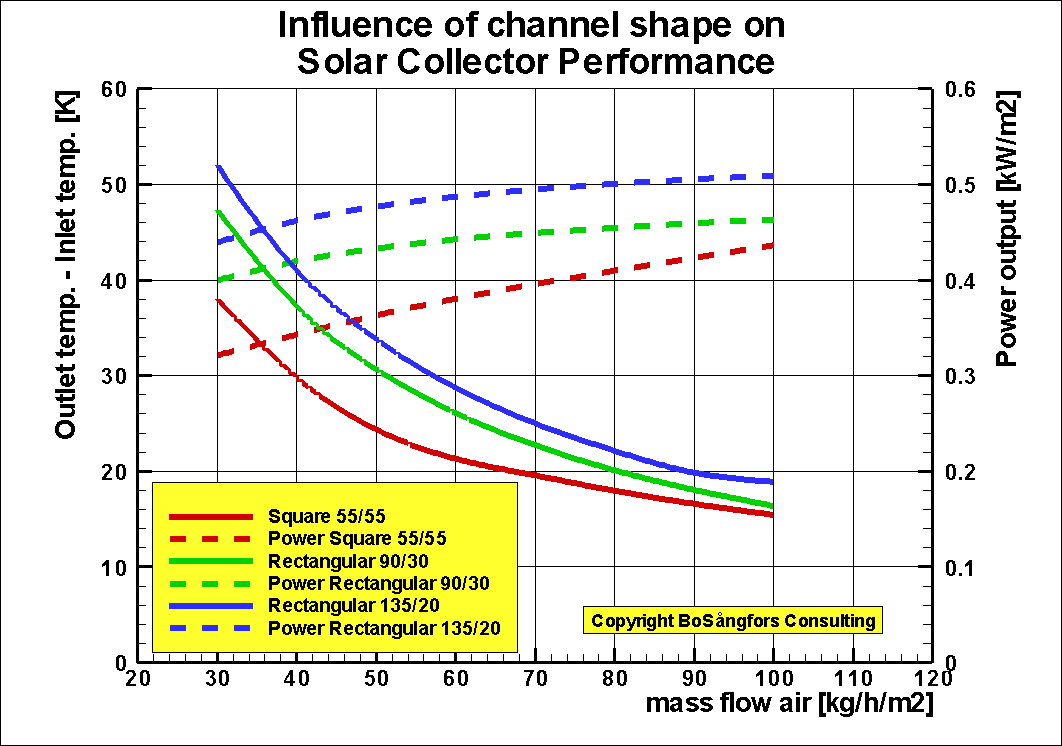

SOLAR COLLECTORS

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

Influence of channel shape on Solar Collector Performance

PICTURE BELOW:

-

- You increase the heat transfer surface when the ratio (length of flange/distance between flanges) increases

- T

Length of flange = 135 mm

Distance between flanges = 20 mm

Here are examples of some standard designs that one can buy.

See also:

https://www.researchgate.net/publication/301551572_Addition_to_Influence_of_channel_shape_on_Solar_Collector_Performance

https://www.researchgate.net/publication/299599242_Influence_of_channel_shape_on_Solar_Collector_Performance

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

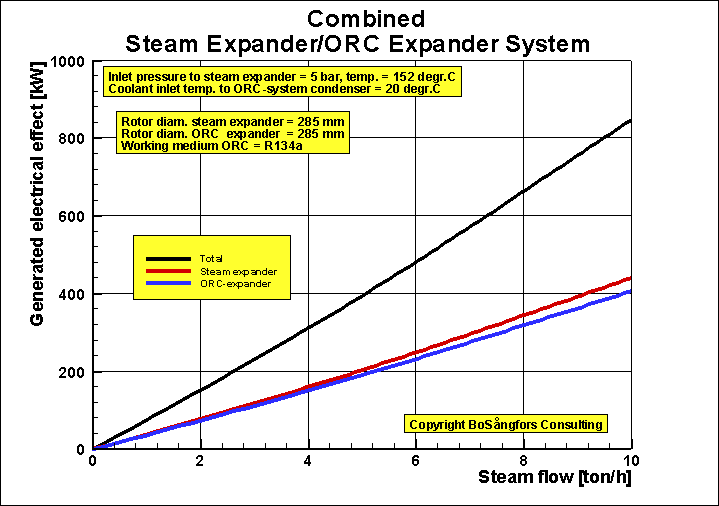

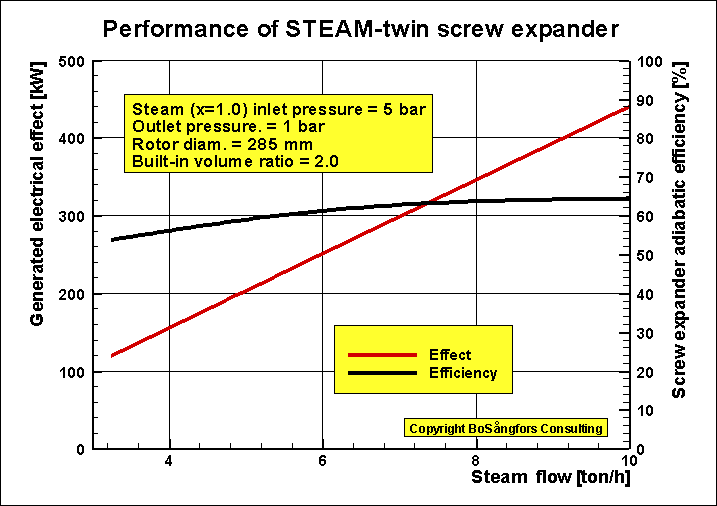

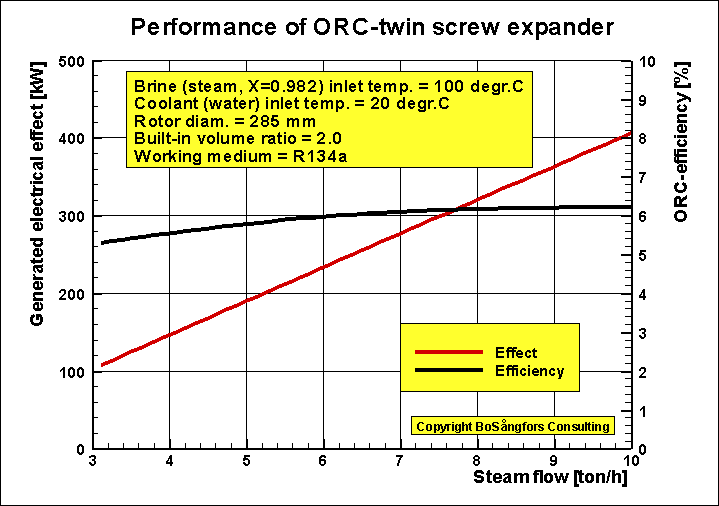

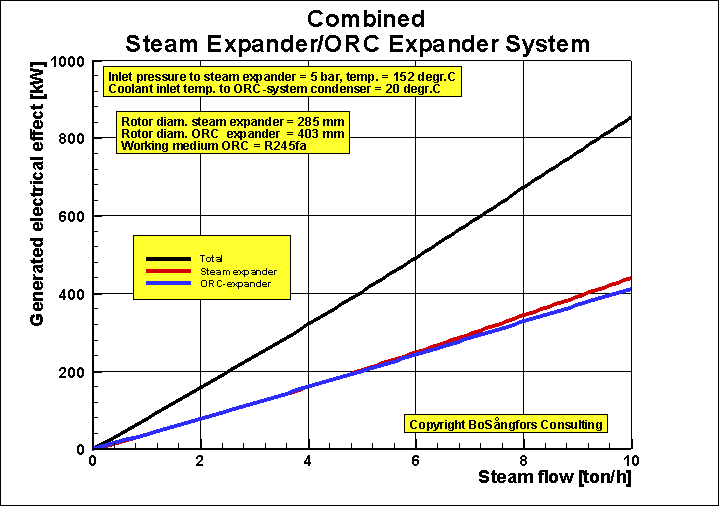

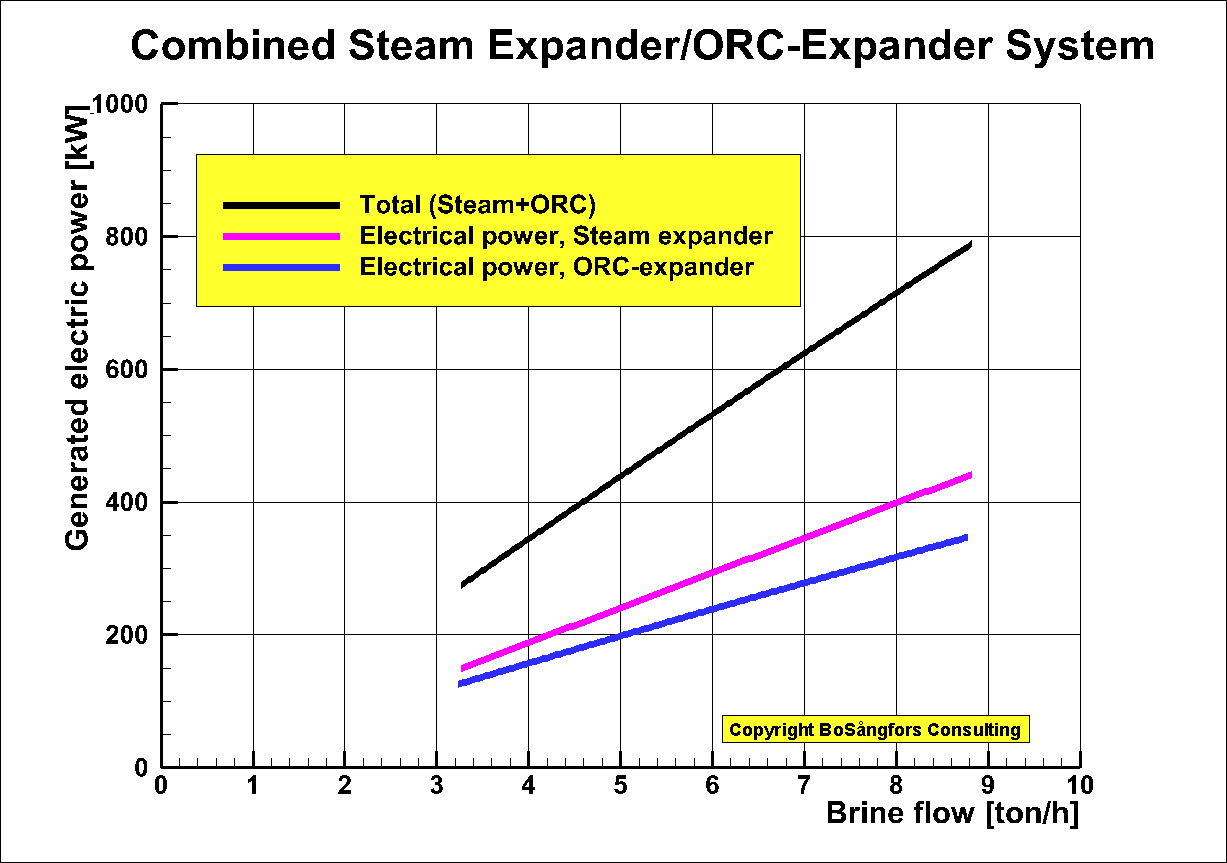

SCREW COMPRESSORS/EXPANDERS

Estimated Performance of a Waste Heat Recovery System

Stage 1: Steam Screw Expander

Stage 2: ORC using Screw Expander

Stage 1: Steam Screw Expander in above Combined System

Stage 2: ORC using Screw Expander in above Combined System

Change the working medium in stage 2 from R134a to R245fa.

Then it is necessary to change the rotor diam. from 285 mm to 403 mm

to get the same performance.

Why not use a turbine instead, since the expansion takes place in the superheated region?

Any objections?

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

Using two Helical Screw Expanders of same size for generation of

Power from a 2 stage Heat Recovery System

Stage 1: Steam Screw Expander, Diam. = 285 mm

Stage 2: ORC using

R245fa Screw Expander, Diam. = 285 mm

Fig.1

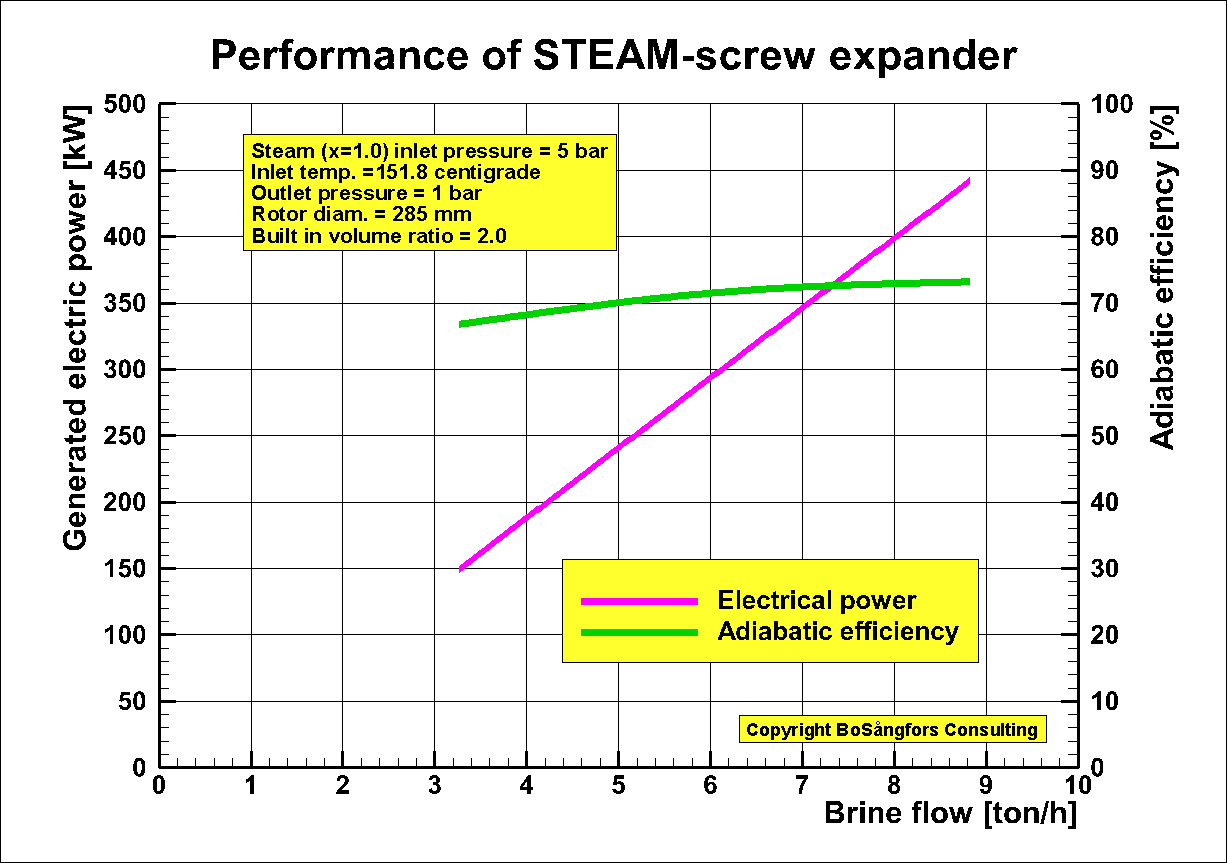

Stage 1: Steam Screw Expander in above Combined System

Rotor diameter = 285 mmBuilt-in volume ratio = 2.0

Inlet/Outlet pressure = 5/1 bar

Inlet/Outlet temperature 151.8/99.6 centigrade

Male rotor tip speed = 41.5 < Vtip < 124.5 m/s

Generator efficiency = 0.95

Fig.2 shows that the generated effect and the adiabatic efficiency as a function of the steam flow leaving the steam expander.

Fig.2

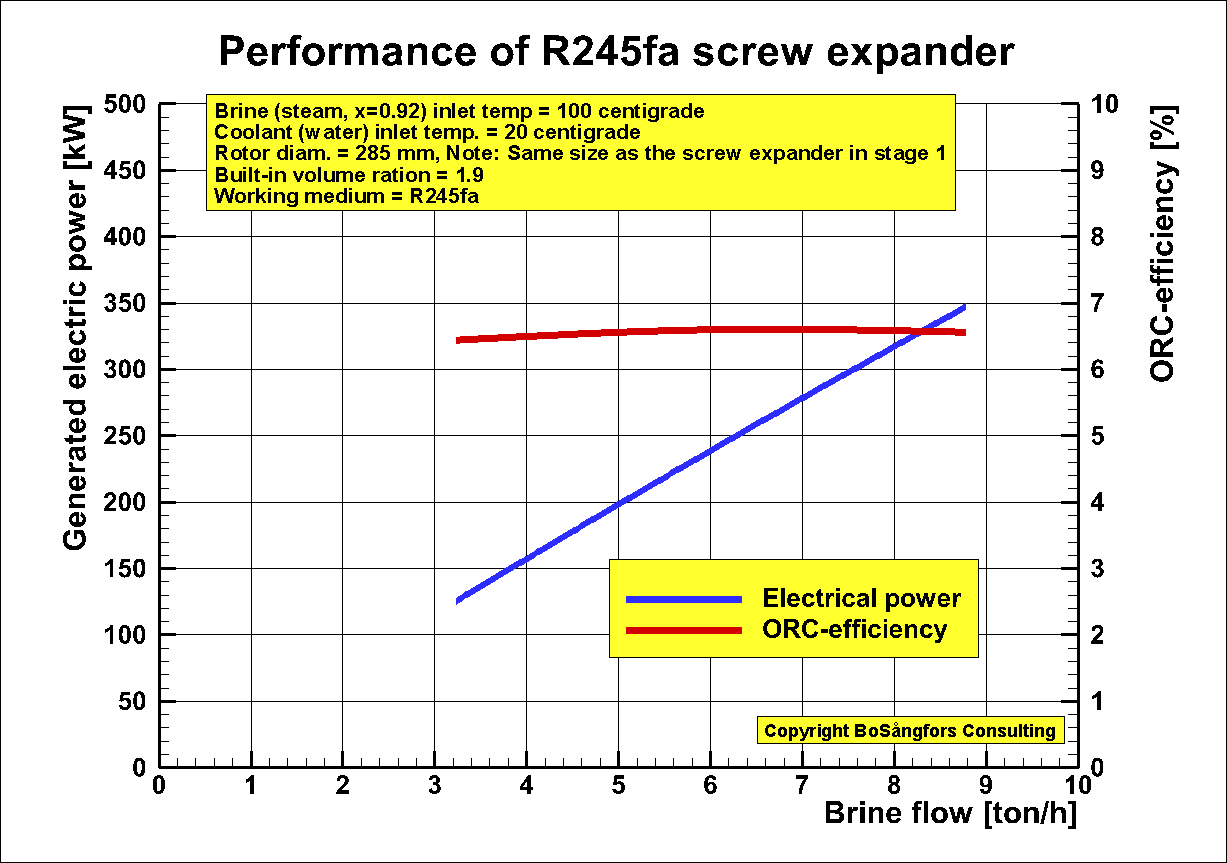

Stage 2: ORC using Screw Expander in above Combined System

Rotor diameter = 285 mmBuilt-in volume ratio = 1.9

Male rotor tip speed = 41.5 < Vtip < 124.5 m/s

Brine = Water of steam quality x=0.92 leaving the steam expander stage 1

Coolant = Water

Brine temp in = 100 centigrade

Coolant temp in = 20 centigrade

Working medium =R245fa

R245fa quality x at expander inlet = 1.0

Evaporation temp = (11*Brine temp + 5*Coolant temp)/16 = 75 centigrade

Evaporation pressure = 6.9510 bar

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 = 35 centigrade

Condensing pressure = 2.1172 bar

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

Generator efficiency = 0.95

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Fig 3 shows generated power and ORC-efficiency.

Fig.3

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

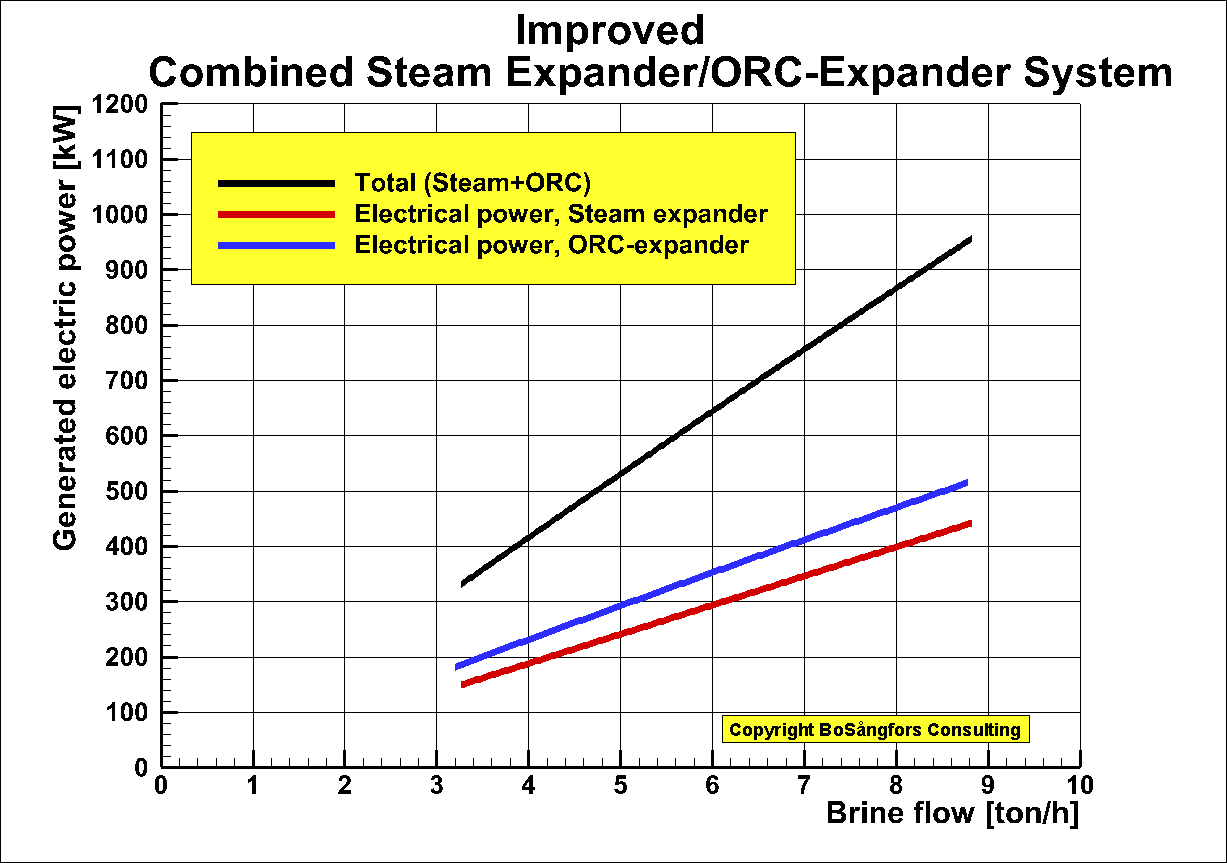

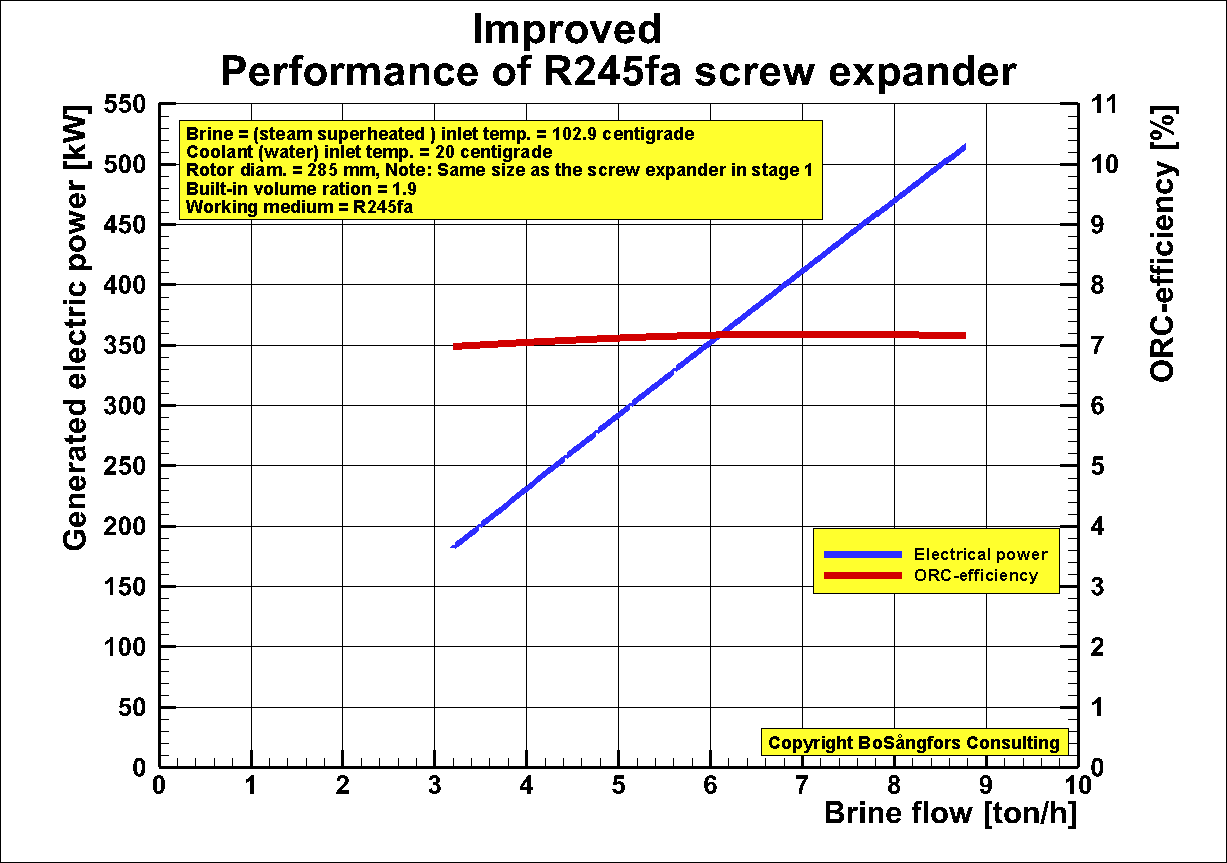

Improvement of

Using two

Helical Screw Expanders of same size for generation of Power from a

2 stage

Heat Recovery System

Stage 2: ORC using R245fa Screw

Expander, Diam. = 285 mm

The two screw expanders

in this system are dry expanders of the same size, namely diam. = 285mm.

Tip speeds: Steam

expander 41.5 to 124.5 m/s, R245fa ORC-expander 30 to 90 m/s

Fig.1 shows the generated effect as a function of the brine flow in the system.

Fig.1.

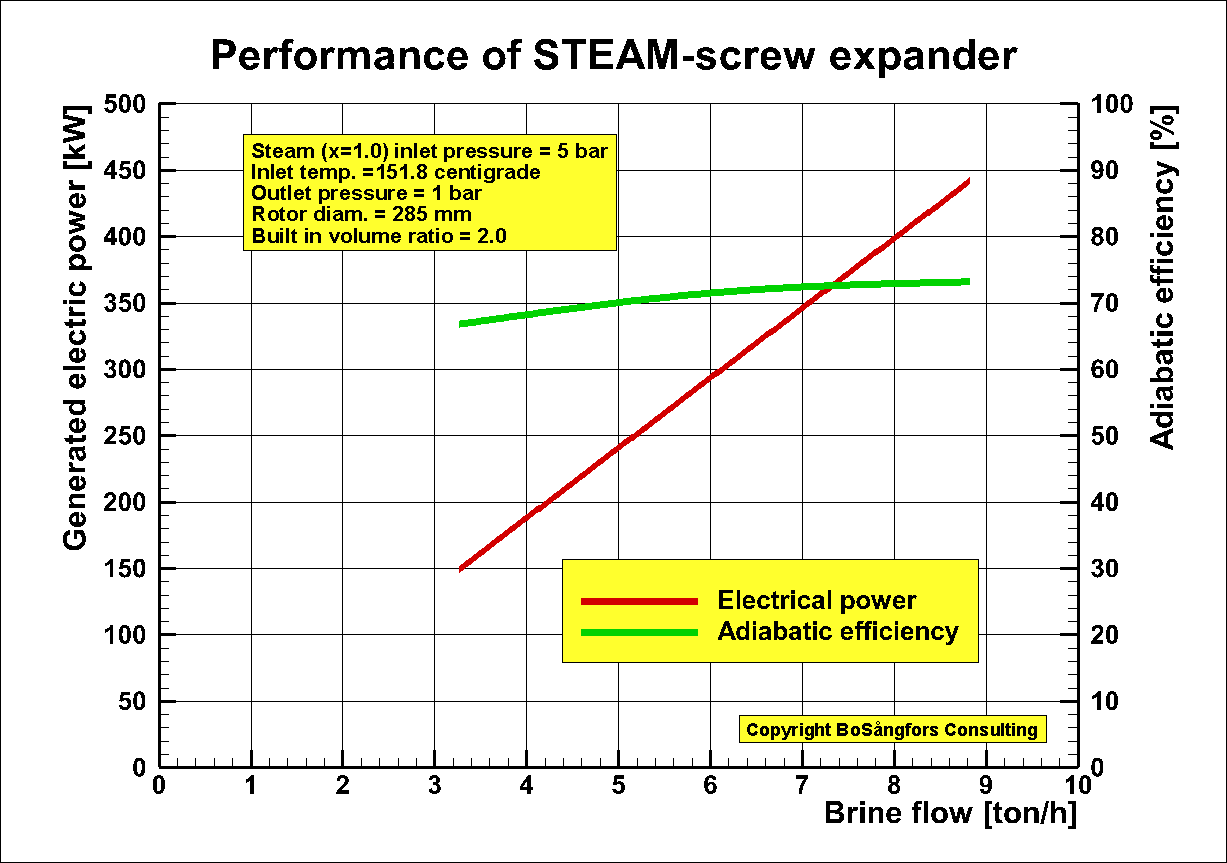

Stage 1: Steam Screw Expander in

above Combined System

Rotor diameter = 285 mm

Built-in volume ratio = 2.0

Inlet/Outlet pressure = 5/1 bar,

Inlet/Outlet temperature 151.8/102.9 centigrade

Male rotor tip speed = 41.5 < Vtip < 124.5 m/s

Generator efficiency = 0.95

Fig.2 shows that the generated effect and the adiabatic efficiency as a function of the brine (steam) flow leaving the steam expander.

Fig.2

Stage 2: ORC using Screw Expander in

above Combined System

Rotor diameter = 285 mm

Built-in volume ratio = 1.9

Male rotor tip speed = 30 < Vtip < 90 m/s

Brine = Steam of temperature 102.9 centigrade leaving the

steam expander stage 1

Coolant = Water

Brine temp in = 102.9 centigrade

Coolant temp in = 20 centigrade

Working medium =R245fa

R245fa quality x at expander inlet = 1.0

Evaporation temp = 85 centigrade

Evaporation pressure = 8.9278 bar

Condensing temp = 35 centigrade

Condensing pressure = 2.1172 bar

Temp. efficiency (Evaporator +Preheater) = 90 %

Temp. efficiency Condenser = 90 %

Generator efficiency = 0.95

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Fig 3 shows generated power and ORC-efficiency.

Fig.3

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

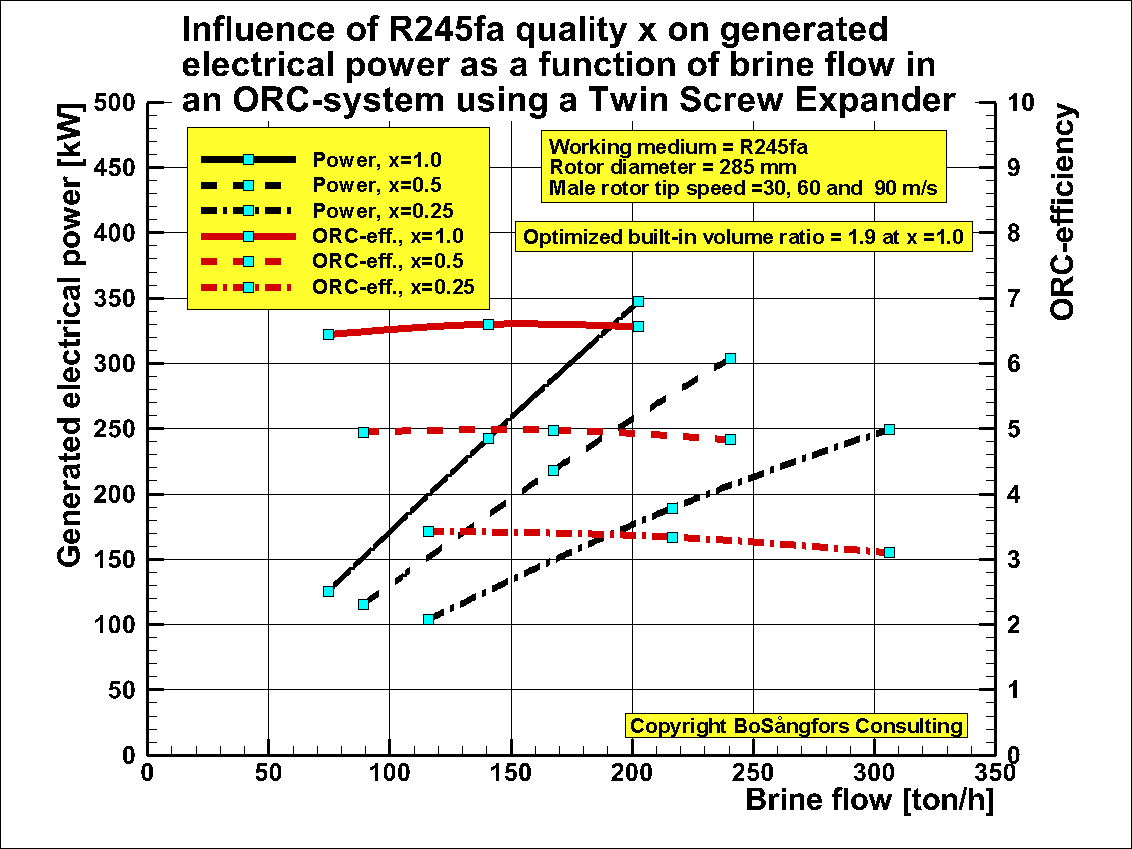

Increased brine flow

and decreased output of electrical power due to decreased R245fa steam quality x

from an ORC-system using a Twin Screw Expander.

This graph is just to show the importance of having a good steam quality

at the screw expander inlet.

One can say that this is typical for all displacement machines - not

only screw expanders.

-----------------

Brine = Water

Coolant = Water

Working medium =R245fa

R245fa quality x at expander inlet = 1.0, 0.5 and 0.25

Built-in volume ratio = 1.9, Optimized at x=1.0

Rotor diameter = 285 mm

Brine temp in = 100 centigrade

Coolant temp in = 20 centigrade

Evaporation temp = (11*Brine temp + 5*Coolant temp)/16 = 75 centigrade

Evaporation pressure = 6.9510 bar

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 = 35 centigrade

Condensing pressure = 2.1172 bar

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

---------------------------------------------------------------------------------------------------------------------------------

Fig 1 shows the

generated power and ORC-efficiency. As you can see all these parameters decrease

when the quality X at the expander inlet decreases.

As is obvious it is important to have a good quality x at the expander inlet.

Fig. 1

ญญญญญญญญญญญญญญญญญญญ-------------------------------------------------------------------ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

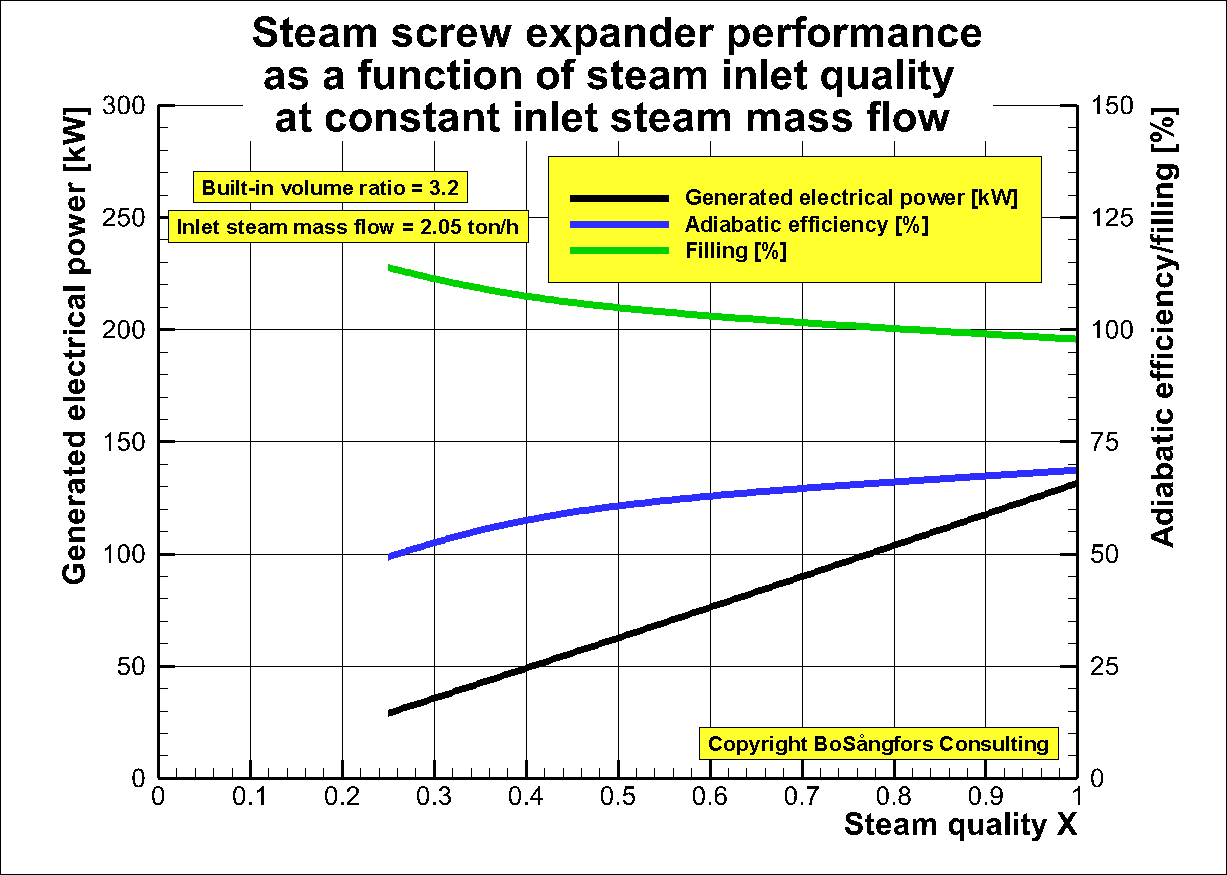

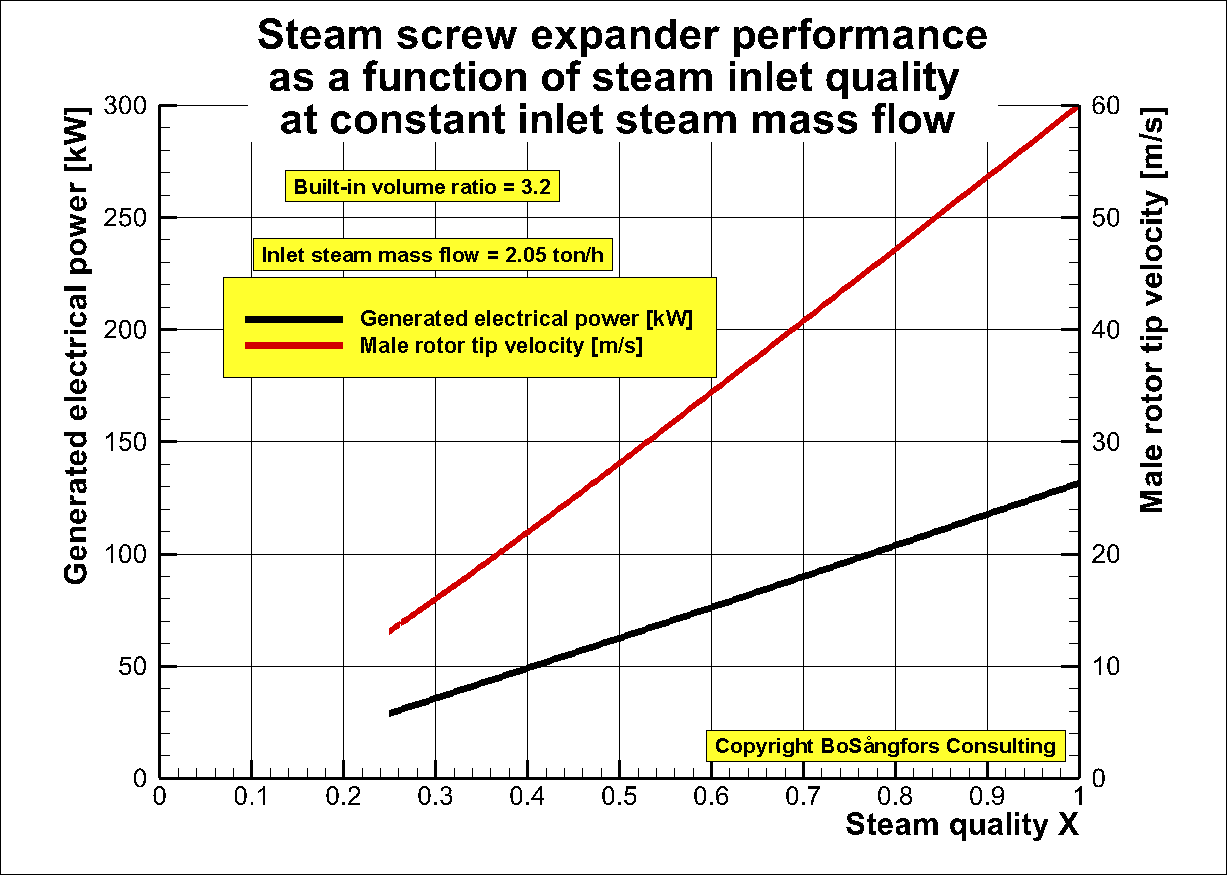

Adjusting of Steam

Screw Expander rotor tip speed in order to keep the inlet mass flow constant at

different inlet steam quality X.

This is an addition to the data file Importance of having good steam quality x at the inlet of a Steam Screw Expander generating electric power and Effect of inlet steam quality X if the inlet steam mass flow is constant.

In these calculations

the steam mass flow is kept constant by changing the male rotor tip speed at

different steam quality x.

As can be seen the

generated power decreases with decreasing inlet steam quality x.

Other

data are:

Rotor

diameter = 200 mm

Inlet/Outlet pressure = 8/1 bar at all calculated steam quality points

Inlet/Outlet temperature 170.4/99.6 centigrade at all calculated steam quality

points

Inlet steam mass flow = 2.05 ton/h in all

calculations.

Built-in volume ratio = 3.2, optimized at steam quality x =1.0

Generator efficiency = 0.95

Fig.1 shows that the generated effect decreases with decreasing steam quality.

Fig. 1

Fig. 2

shows the variation of the male rotor tip speed to get the inlet steam mass flow

to be constant,

Fig. 2

ญญญญญญญญญญญญญญญญญญญ-------------------------------------------------------------------ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

New version of Effect

of inlet steam quality X if the inlet steam mass flow is constant.

This is an

addition to the data file Importance of having good steam quality x at the

inlet of a Steam Screw Expander generating electric power and Effect of inlet

steam quality X if the inlet steam mass flow is constant earlier uploaded on

Research Gate

In these calculations the steam mass flow is kept constant by changing the built-in volume ratio.

As can be seen the

generated power and the filling decreases with decreasing inlet steam quality.

The adiabatic efficiency is maximum at x=3.0

Other

data are:

Rotor

diameter = 200 mm

Inlet/Outlet pressure = 8/1 bar at all calculated steam quality points

Inlet/Outlet temperature 170.4/99.6 centigrade at all calculated steam quality

points

Inlet steam mass flow = 7.2 ton/h in all

calculations.

Male rotor tip speed = 60 m/s

Generator efficiency = 0.95

Fig.1 shows that the generated effect and the filling decreases with decreasing

steam quality.

The adiabatic efficiency is maximum at x=0.3.

Fig. 1

Fig. 2 shows the variation of the built-in volume ratio to get the inlet steam mass flow to be constant

Fig. 2

ญญญญญญญญญญญญญญญญญญญ-------------------------------------------------------------------ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

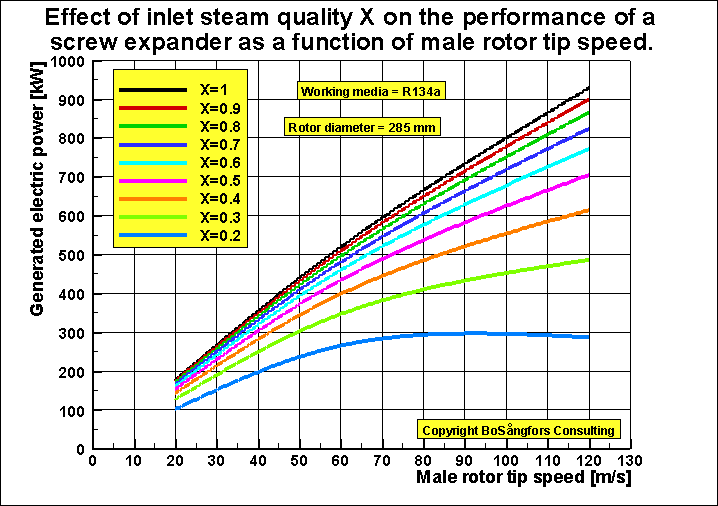

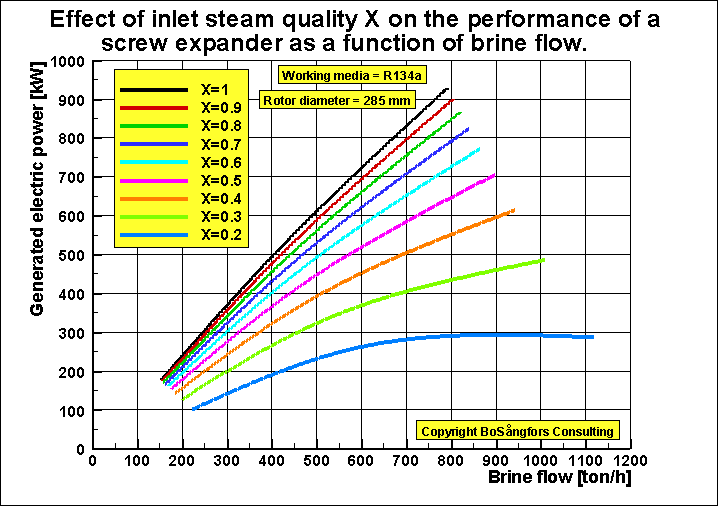

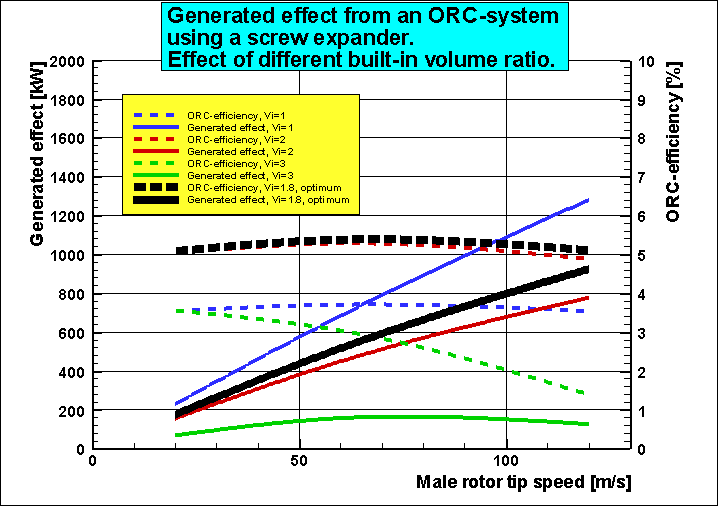

Effect of steam quality X

upon the performance of an ORC-system,

which uses a screw expander for driving a generator producing electrical power

In order to give more information about the effects of

various steam quality X,

when using a screw expander in an ORC-system these

calculations are presented.

This data set presents 2 graphs, where fig.1 shows the

performance as a function of the male rotor tip speed and fig.2

the performance as a function of the brine flow.

The expander is a dry screw expander with synchronizing

bearings

Rotor diameter = 285 mm

Built in volume ratio = 1.8, which is optimized at male

rotor tip speed = 60 m/s

Brine = Water

Coolant = Water

Brine temp = 90 centigrade

Coolant temp = 20 centigrade

Evaporation temp. = (11*Brine temp + 5*Coolant temp)/16

= 68.125 centigrade

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 =

33.125 centigrade

These temperatures are valid for all presented

calculations.

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temperature efficiency Evaporator = 90 %

Temperature efficiency Condenser = 90 %

Working media = R134a

Generator efficiency = 95 %

Calculation results:

As can be seen from fig. 1 and 2 the generated power

decreases with decreasing quality X.

Fig. 1. Performance as a function of male rotor tip speed

Fig. 2. Performance as a function of brine flow

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

Effect of different built-in volume ratio

upon the performance of an ORC-system,

which uses a helical screw expander for

driving a generator producing electrical power.

In order to give more information about the effects of

various built-in volume ratio Vi, when using a screw expander in an

ORC-system these calculations are presented.

This data

set presents 2 graphs, where fig.1 shows the performance as a function of the

male rotor tip speed and fig.2 the performance as a function of the brine flow.

The

expander is a dry screw expander with synchronizing bearings

Rotor

diameter = 285 mm

Built in

volume ratio = 3 cases, namely 1, 2, 3

Brine =

Water

Coolant =

Water

Brine

temp = 90 centigrade

Coolant

temp = 20 centigrade

Evaporation temp. = (11*Brine temp + 5*Coolant temp)/16

Condensing temp = (3*Brine temp + 13*Coolant temp)/16

These

temperatures are valid for all presented calculations.

Pump

losses in ORC system are included.

Brine

pump losses are not included.

Coolant

pump losses are included.

Working media = R134a

Quality x = 1.0 at the screw expander inlet

Calculation results:

As can be

seen from fig. 1 the built-in volume ratio = 1 gives the highest production of

power, but the ORC-efficiency is not so high.

At Vi=2 the produced power is lower, but now the efficiency has increased and is very close to the optimized Vi=1.8.

At Vi=3 the produced power begins to decrease after male rotor tip speed = 80 m/s.

Please note that the ORC-efficiency decreases when the tip speed increases.

This is due to the increased pressure drop at the expander inlet.

Fig. 1. Performance as a function of male rotor tip speed

As can be seen from fig.2 the operational range is

strongly reduced when Vi

is increased.

For Vi = 3 the

pressure drop loss at the inlet is so high that the operational range is

extremely reduced.

At brine flow above 130 m3/h

the generated effect starts to decrease.

Fig. 2. Performance as a function of brine flow

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

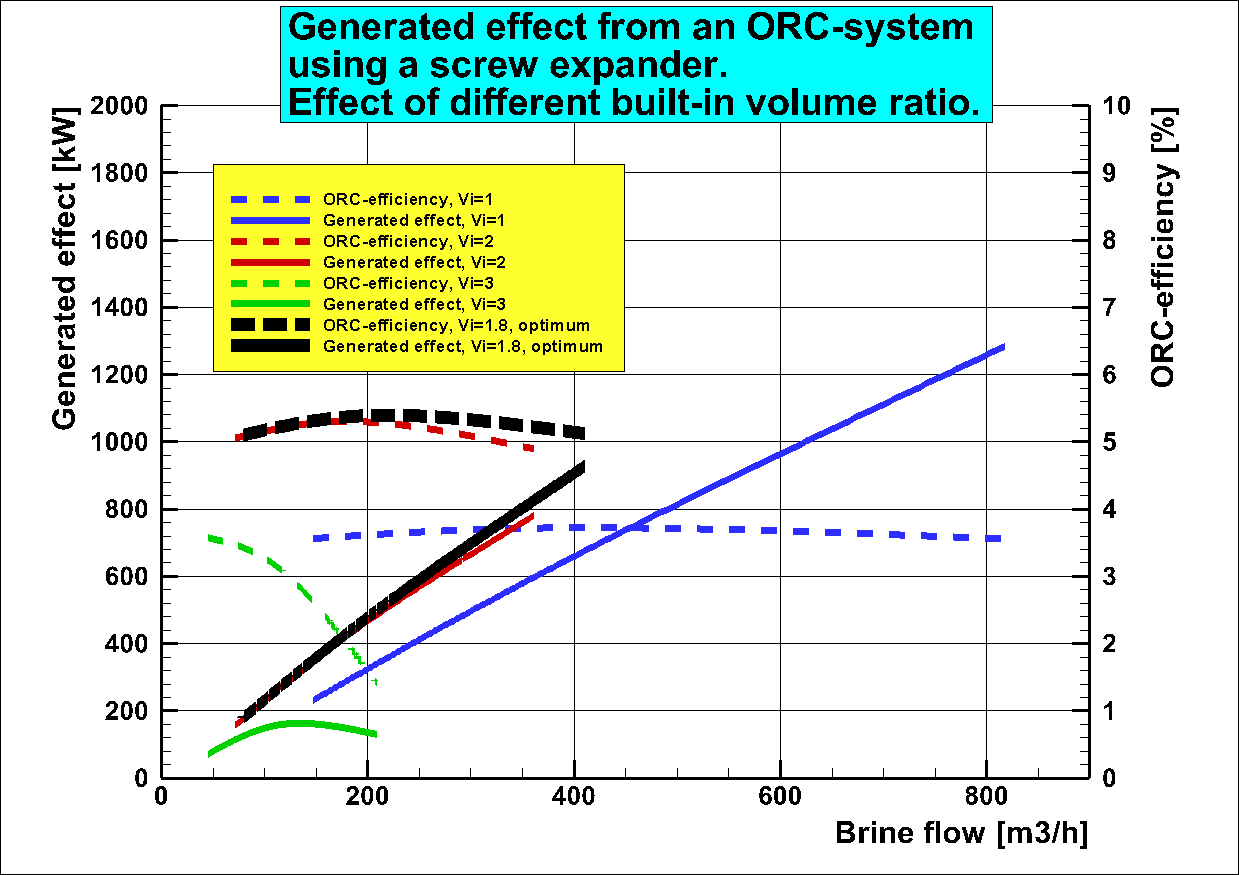

Influence of different built-in volume ratio

on the generated power from of an ORC, using

a screw expander for

driving a generator producing electrical power.

In order to give more information about

the effects of various built-in volume ratio Vi, when

using a screw expander in an ORC-system these calculations are

also presented.

The presented graph shows the generated power and the

ORC-efficiency a function of the brine flow.

The

expander is a dry screw expander with synchronizing bearings

Rotor diameter = 285 mm

Male rotor tip speed is from 30 m/s

up to 110 m/s.

The present results are for built-in volume ratio 1, 2 and 3

Brine =

Water

Coolant =

Water

Brine

temp = 130 centigrade

Coolant

temp = 20 centigrade

Evaporation temp. = (11*Brine temp + 5*Coolant temp)/16

Condensing temp = (3*Brine temp + 13*Coolant temp)/16

These

temperatures are valid for all presented calculations.

Pump

losses in ORC system are included.

Brine

pump losses are not included.

Coolant

pump losses are included.

Working media = R236fa

Quality x = 1.0 at the screw expander inlet

Calculation results:

As can be seen from the graph the built-in volume ration Vi = 1

gives the highest production of power but the ORC-efficiency is

not so high.

At Vi =2 the produced power is lower, but now the ORC-efficiency

has increased.

At Vi =3 the

produced power is even more low and the ORC-efficiency as high as 7.6 % at 60 m3/h brine flow.

The operational range is strongly reduced when Vi is reduced.

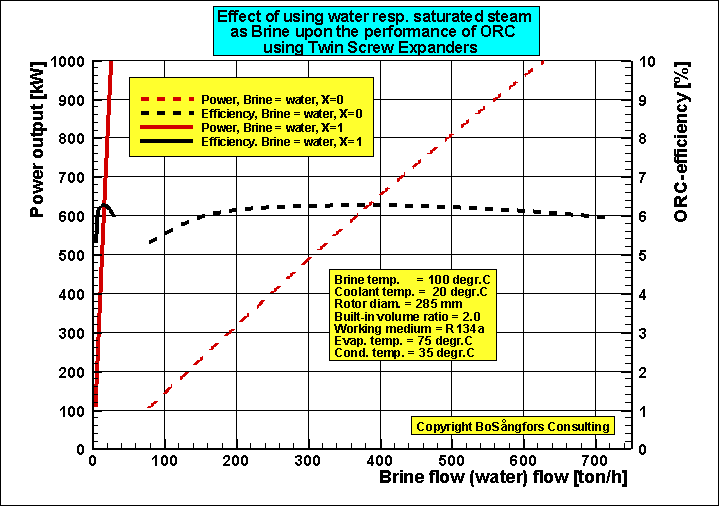

Performance as a function of brine flow

BoSๅngfors Consulting, Sweden

This picture shows the effect of using saturated steam instead of water.

As can be seen the use of saturated steam is much more efficient than the use of water.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

Influence of different working medium on ORC Performance

Brine = water

Coolant = water

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

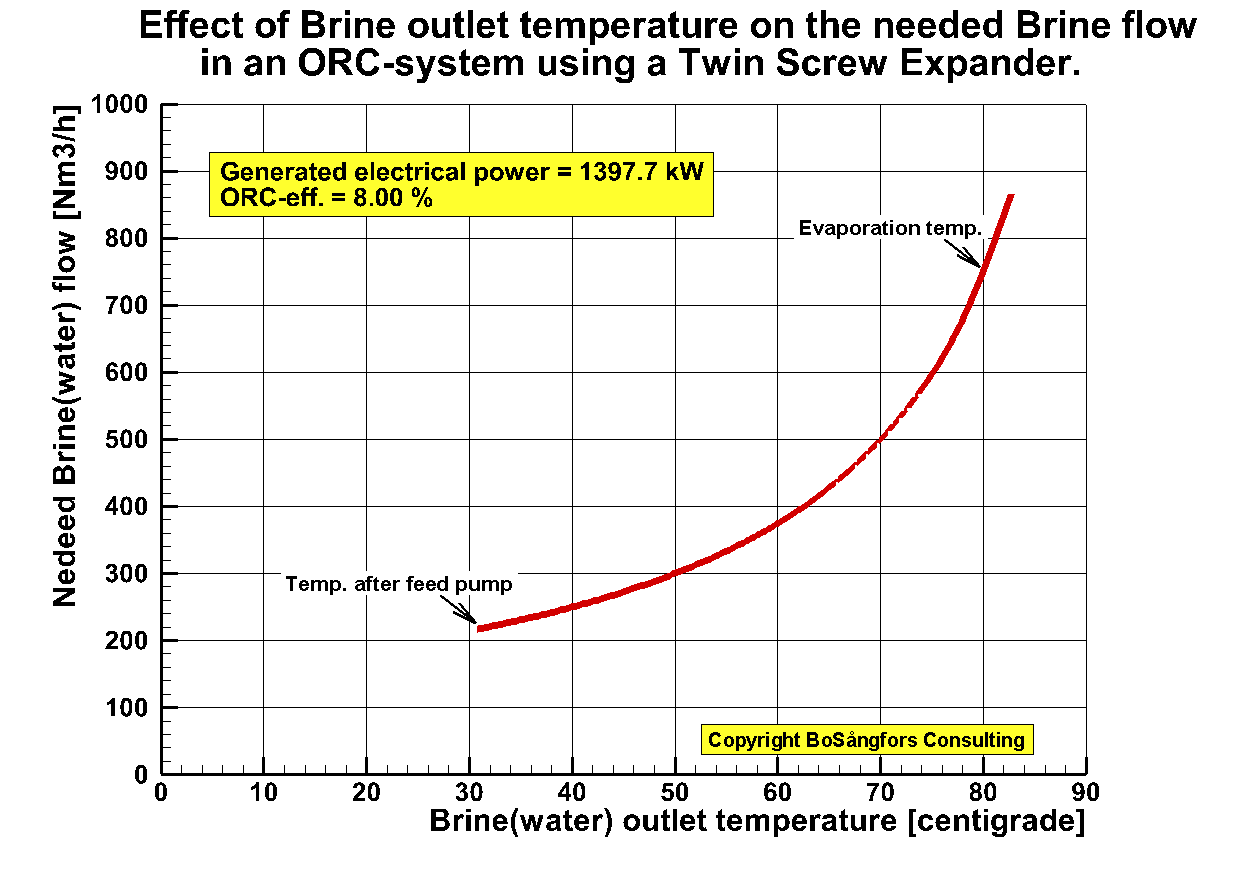

Effect of Brine outlet temperature on the needed Brineflowin an ORC-systeem using a Twin Screw Expander

As

is well known it is important to have a good heat transfer from the brine to the

working media.

The intention of this short data set is to show how the brine outlet temperature

effects the needed brine flow.

-----------------

Brine = Water

Coolant = Water

Working medium =Ammonia, x=1.0 at the expander inlet

Built-in volume ratio =2.0

Rotor diameter = 285 mm

Male rotor tip speed = 60 m/s

Brine temp in = 100 centigrade

Coolant temp in = 20 centigrade

Evaporation temp = 80 centigrade

Evaporation pressure = 41.42 bar

Condensing temp = 30 centigrade

Condensing pressure = 11.67 bar

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 25-100 %

Temp. efficiency Condenser = 90 %

Generated power = 1397.7 kW

ORC-efficiency = 8.00 %

---------------------------------------------------------------------------------------------------------------------------------

Fig 1 shows the

needed brine flow as a function of the brine outlet temperature.

As is obvious it is important to have preheater and evaporator with good heat transfer.

Fig.1

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

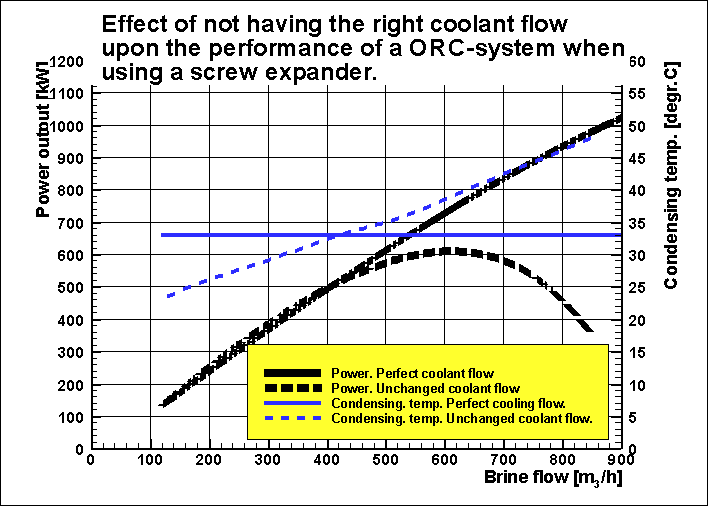

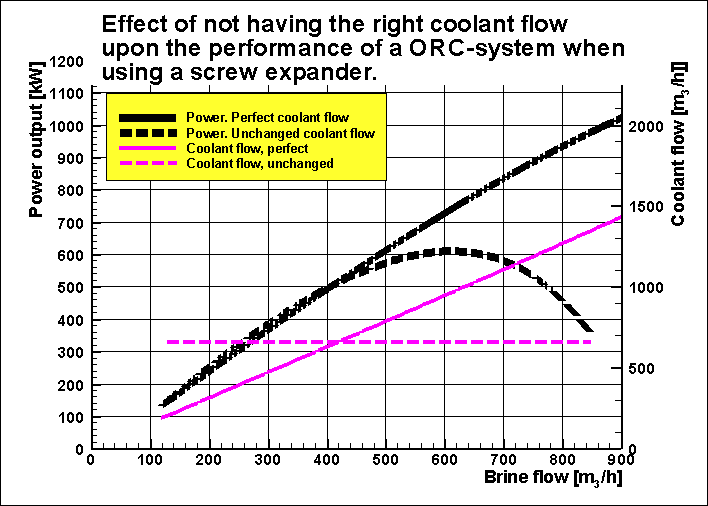

Effect of not having the right coolant flow upon the performance of an ORC-system when using a screw expander.

Fig 1 and 2 show what happens if

you change the brine flow but have the coolant flow constant. As is obvious it

is important to have enough coolant flow if you want an efficient ORC

performance.

Brine =

Water

Coolant = Water

Working medium =R134a, x=1.0 at

expander inlet

Built in volume ratio =1.8

Brine temp in = 90 degr.C

Brine flow : See fig 1 and fig 2.

Coolant temp in = 20 degr.C

Coolant flow =

See fig 2. Showing the perfect and the unchanged condition

R134a, x=1.0

Built in volume ratio =1.8

Brine temp in = 90 degr.C

Brine flow : See graph

Evaporationtemp = (11*Brinetemp + 5*Coolanttemp)/16

Condensingtemp = (3*Brinetemp + 13*Coolanttemp)/16

This

value of the condensing temp. is valid for the perfect condition.

At

constant cooling flow see fig 2.

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

Fig.1

Fig.2

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

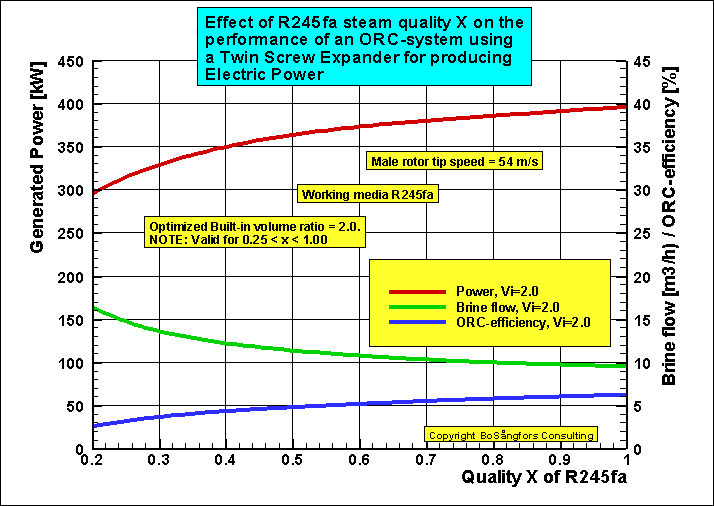

Fig 1 shows what happens if you change the steam quality x at the inlet of the

screw expander. As you can see the generated power as well as the ORC-efficiency

decreases as x decreases, but the brine flow increases.

As is obvious it is important to have a good quality x at the expander inlet.

Brine = Water

Coolant = Water

Working medium =R245a, 0.2 < x <1.0 at the expander inlet

Built-in volume ratio =2.0, NOTE: This is the optimized built-in volume ratio in

all calculations

Rotor diameter = 403 mm

Male rotor tip speed = 54 m/s

Brine temp in = 100 centigrade

Coolant temp in = 20 centigrade

Evaporation temp = (11*Brine temp + 5*Coolant temp)/16 = 75 centigrade

Evaporation pressure = 6.95 bar

Condensing temp = (3*Brine temp + 13*Coolant temp)/16 = 35 centigrade

Condensing pressure = 2.12 bar

Pump losses in ORC system are included.

Brine pump losses are not included.

Coolant pump losses are included.

Temp. efficiency Evaporator = 90 %

Temp. efficiency Condenser = 90 %

Fig

1

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

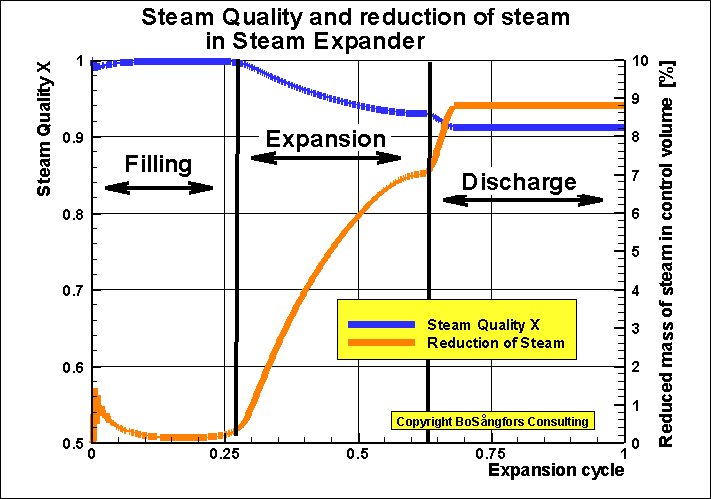

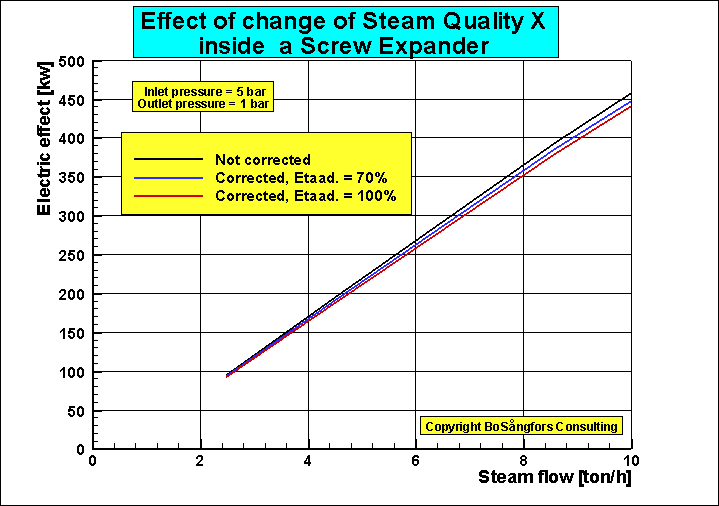

Effect of change of Steam Quality X in a Steam Screw

Expander

In order to find

out the effect of the variation of Steam Quality in a screw expander this

investigation was made.It is assumed that the change is immediate. I.e. no time

factor is taken into consideration, which means that the presented effect is

maximum.

The values for the steam quality are taken from

the program Refprop.

Example:

Steam flow = 8 ton/h.

Reduction of power compared to not corrected:

Assumed adiabatic efficiency

70 % = 2.0 %

Assumed adiabatic efficiency 100 % = 3.5 %

Fig.1

Fig.2

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

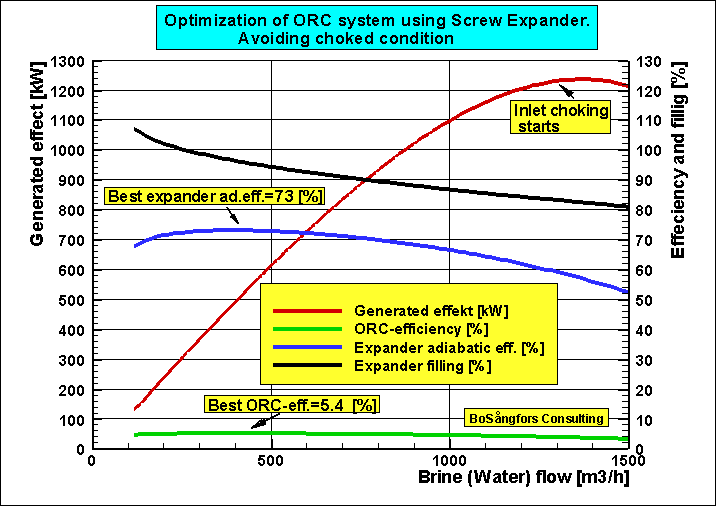

Avoiding inlet flow choking at a Screw Expander inlet

As can be seen it is very important to have a good design point.

Too high brine flow leads to inlet choking at 1350 m3/h.

The best ORC-efficiency is for this screw expander at 400 m3/h.

I.e ORC-eff. = 5.4 %

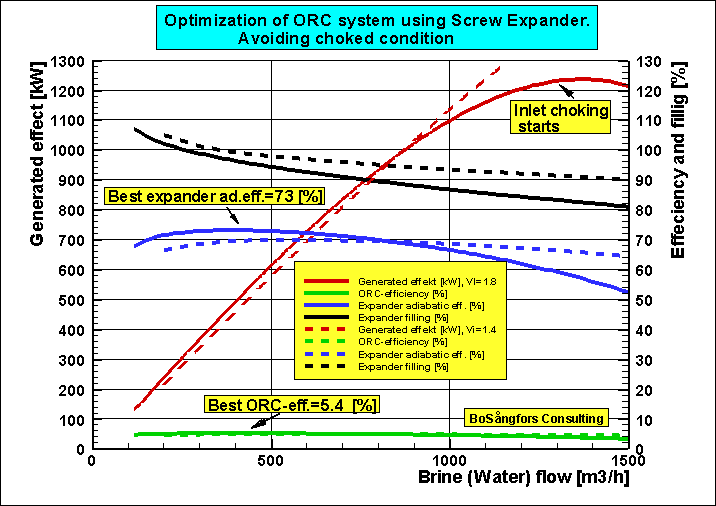

The graph below is the same as this above with the exception that data for Vi =1.4 are added for comparison with data from Vi=1.8

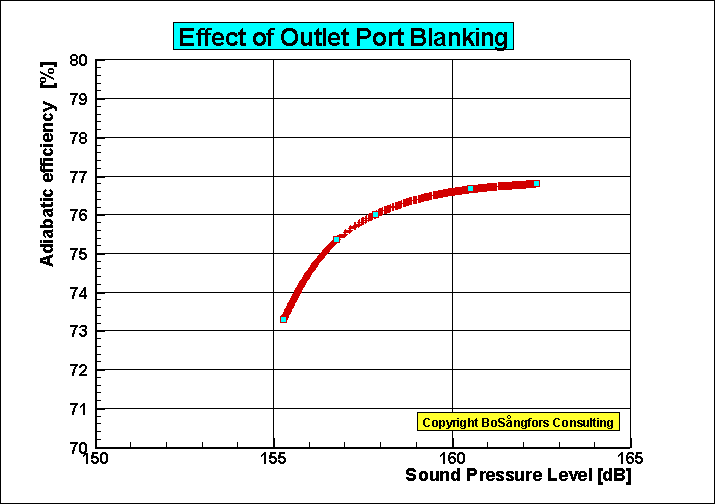

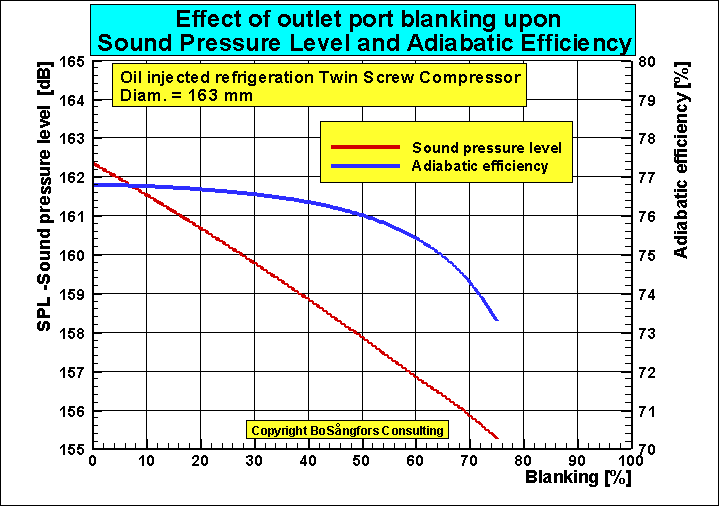

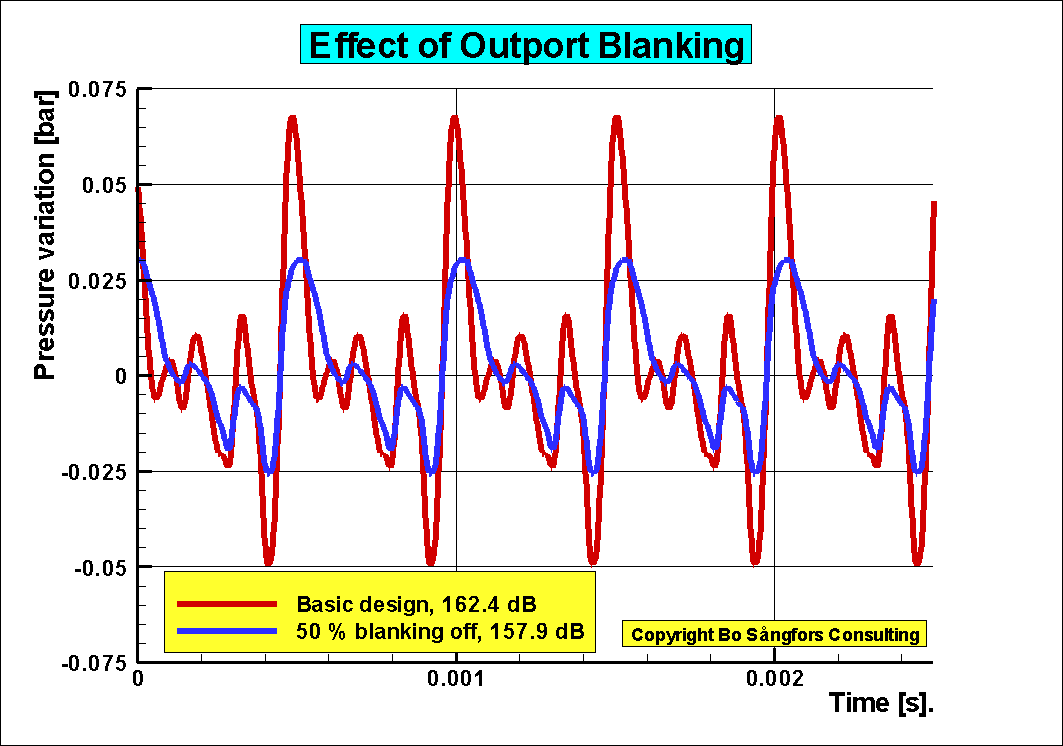

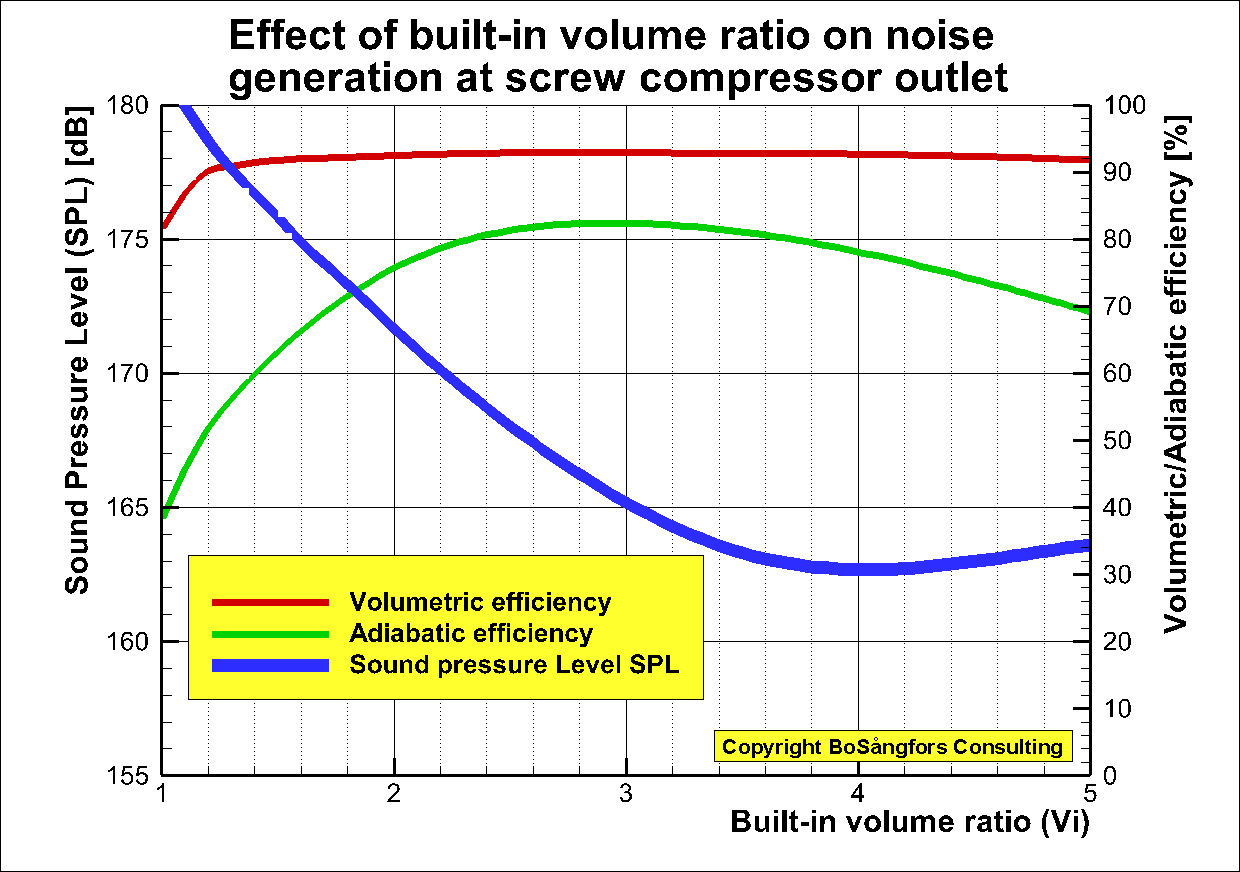

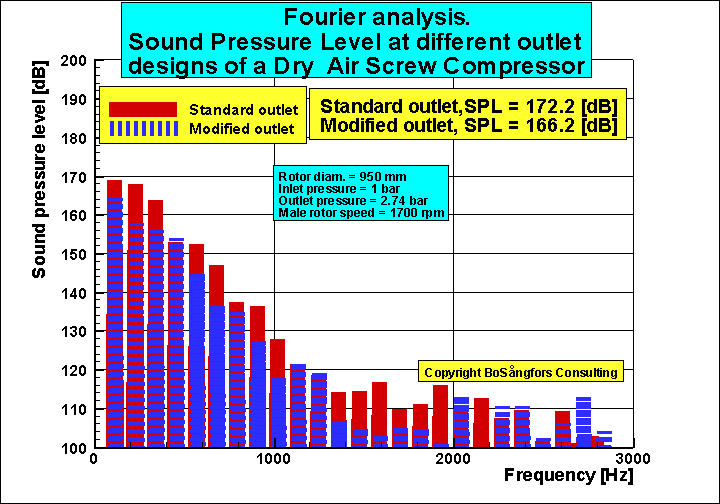

Influence of blanking upon SPL(Sound Pressure Level) of a Screw Compressor Outlet

Results from discussions with Elvedin Mujic, City University London.

In order to

give some information about the effect of different built-in volume ratio upon

the generation of noise from the outlet of a twin screw compressor these

calculations are presented.

![]()

The screw compressor is an oil injected refrigeration screw compressor.

Refrigerant = 134a

Rotor diameter =

162.7 mm

Oil injection rate = 66 lit/min

Male

rotor speed = 3000 rpm

Inlet:

Pressure = 2.006 bar

Temp. = 0

centigrade.

Corresponds

to -10 centigrade evaporation temp. and 10 centigrade superheat.

Outlet:

Pressure =

10.166

bar

Corresponds to 40 centigrade condensing

temp.

The

compressor has a pipe of inside diameter = 250 mm and length = 2000 mm mounted

to the compressor outlet.

The reported

point of sound pressure level SPL is located at the end of the 2000 mm pipe.

Fig. 1

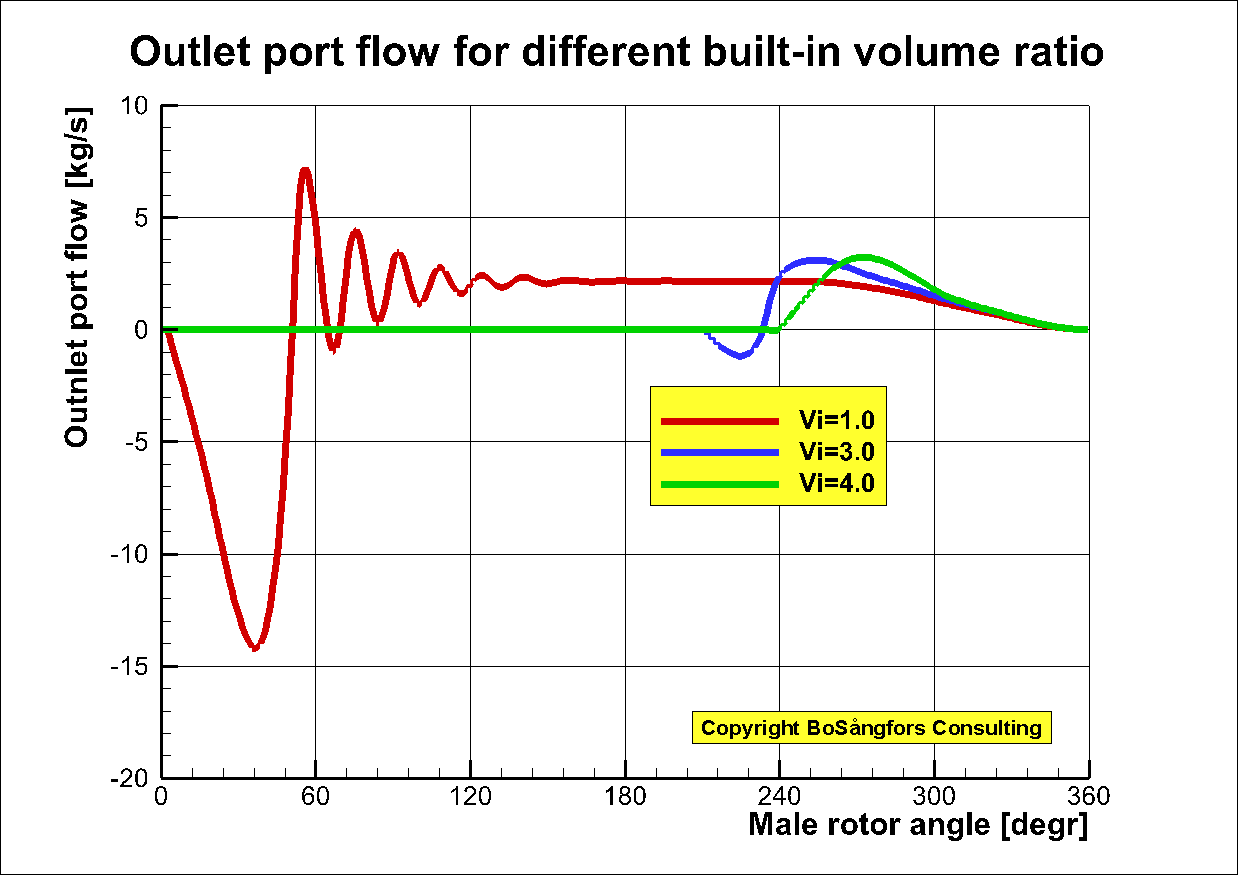

As is shown in fig. 1 the built-in volume ratio Vi is very important for the adiabatic efficiency of a screw compressor, but also for the generation of noise.

It is obvious that the sound pressure level SPL can be very high especially at built-in volume ratio close to 1.

Another

point of interest is that the lowest

SPL is obtained at built-in volume ratio Vi

= 4

and not at 3,

which is the optimum value for adiabatic

efficiency.

A look at fig.2 can explain the presented effects.

As is shown the discharge starts with high backflow into the control volume since the opening pressure in the control volume is close to the filling pressure.

Then a

long discharge procedure starts.

At

Vi =

3

(optimum value) the discharge procedure is much shorter but still starts with a

small backflow.

At

Vi =

4 there is no backflow, which probably together

with a slight blanking effect explains

why the SPL is

lowest.

Fig. 2

Reference:

https://www.researchgate.net/publication/254636763_Modeling_Measurements_and_Analysis_of_Ga s-Flow_Generated_Noise_From_Twin-Screw_Compressors

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

Pressure

and gas/oil temperatures during, filling, compression and discharge of

a screw compressor

Input data:

Gas =Air

Pressure in = 1 bar

Pressure out = 8 bar

Temperature air in = 27 centigrade

Temperature Injected oil in = 60 centigrade

Built-in volume ratio = 4.42

Rotor diameter = 111 mm

Male rotor tip speed = 25 m/s

Closing of inlet port = 375 degr.

Injection of oil = 395 degr.

Opening of discharge port = 635 degr.

--------------------------------------------------------------

Calculated results

---------------------------------------------------------------------

Volumetric efficiency = 0.875

Adiabatic efficiency = 0.778

Outlet temperature = 74.1

---------------------------------------------------------------------------------------------------------------------------------

The computer simulations are performed in accordance with the theory and

assumptions presented in the 1984 Purdue paper

Computer

Simulation of the Oil Injected Twin Screw Compressor.

Input data:

Refrigerant =R134a

Pressure in = 2.928 bar

Pressure out = 10.17 bar

Temperature air in = 10.0 centigrade

Temperature Injected oil in = 40 centigrade

Built-in volume ratio = 2.7

Rotor diameter = 111 mm

Male rotor tip speed = 25 m/s

Closing of inlet port = 375 degr.

Injection of oil = 395 degr.

Opening of discharge port = 593 degr.

---------------------------------------------------------------

Calculated results

---------------------------------------------------------------------

Volumetric efficiency = 0.908

Adiabatic efficiency = 0.754

Outlet temperature = 48.7 centigrade

---------------------------------------------------------------------------------------------------------------------------------

The computer simulations are also performed in accordance with the theory and

assumptions presented in the 1984 Purdue paper

Computer

Simulation of the Oil Injected Twin Screw Compressor.

A comparison of this graph with the above for an oil injected air screw

compressor

shows that the temperature behaviour is different. An explanation for this is

that the physical data for R134a and oil are in the same size order for the

calculations of the refrigeration compressor.

In the dataset Pressure and gas/oil temperatures during, filling, compression and discharge of a screw compressor the gas is air, which have physical data very different from the injected oil.

Fig. 2.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

Leakage analysis of a Twin Screw Compressor.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

Leakage

analysis of a Twin Screw Expander.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

Edstroem Consulting, Sweden

Prediction of pressure in the manifold between Supercharger and Engine in the case of

back-fire.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

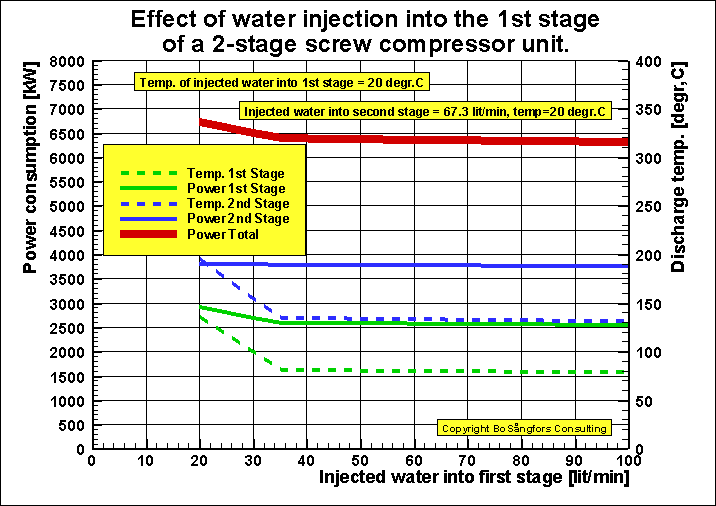

Effect of water injection into the first stage of a two-stage screw compressor unit

These computer simulations are using a modified theory of that described in the papers:

Computer Simulation of Effects from Injection of Different Liquids in Screw Compressors, Purdue 1998 and

"Numerical calculation of effects from injection of different liquids in twin screw compressors, VDI 1998.

The results of the presented calculations show that at water injection rate 67.3 lit/min to the 2nd stage

and 37 lit/min to the 1st stage gives reduced power consumption.

Further increase of the 1st stage water injection rate does not improve the performance very much.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

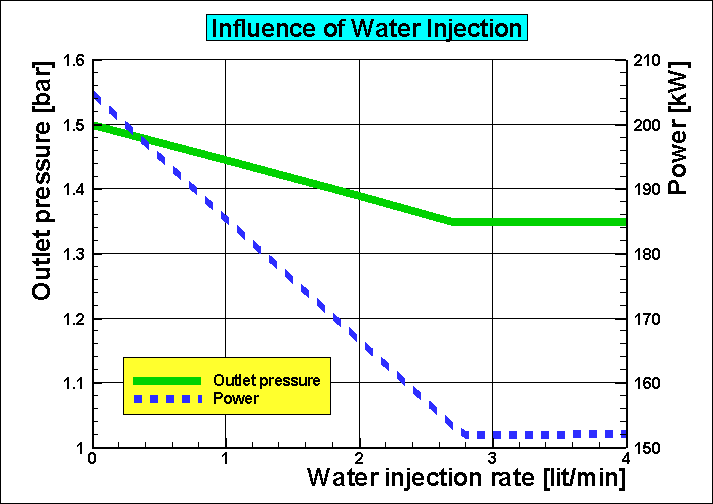

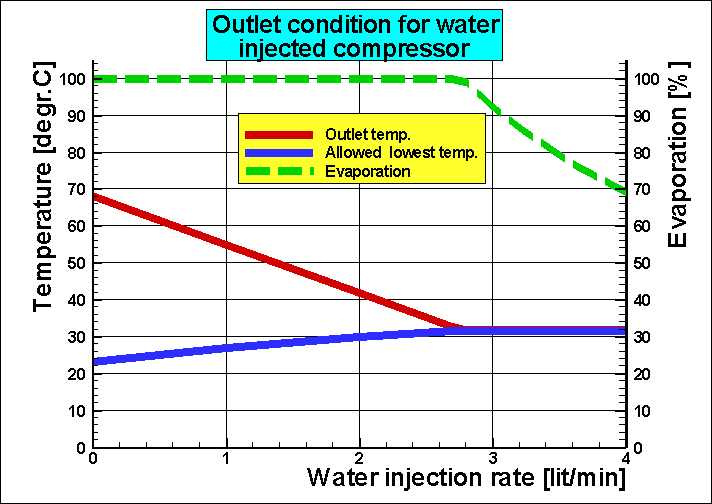

Influence of water injection on outlet parameters after a radial supercharger.

HEAT EXCHANGERS

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

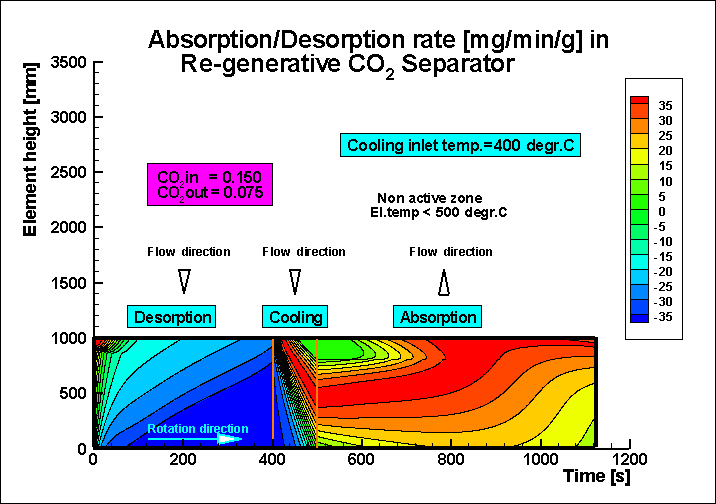

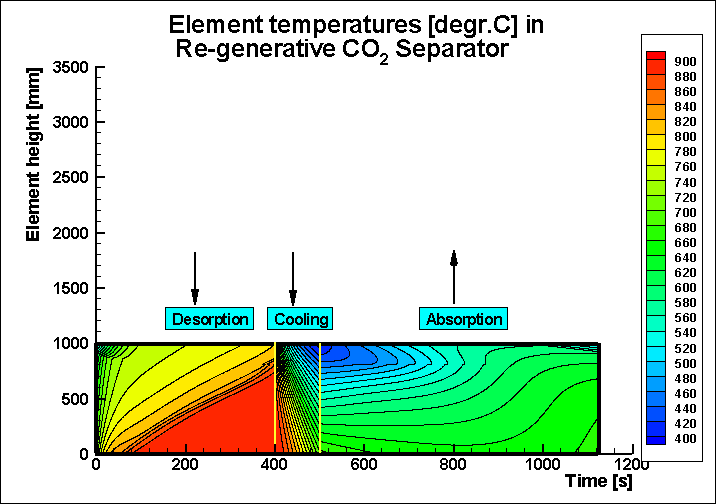

ALSTOM K.K.,

Japan,

ALSTOM Power Energy Recovery GmbH, Germany:

Kobe University, Kobe, Japan

Cleaning of Flue Gas from CO2

by the use of lithium silicate (Li4SiO4) coated on

the heat transfer elements in a rotary

heat exchanger.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

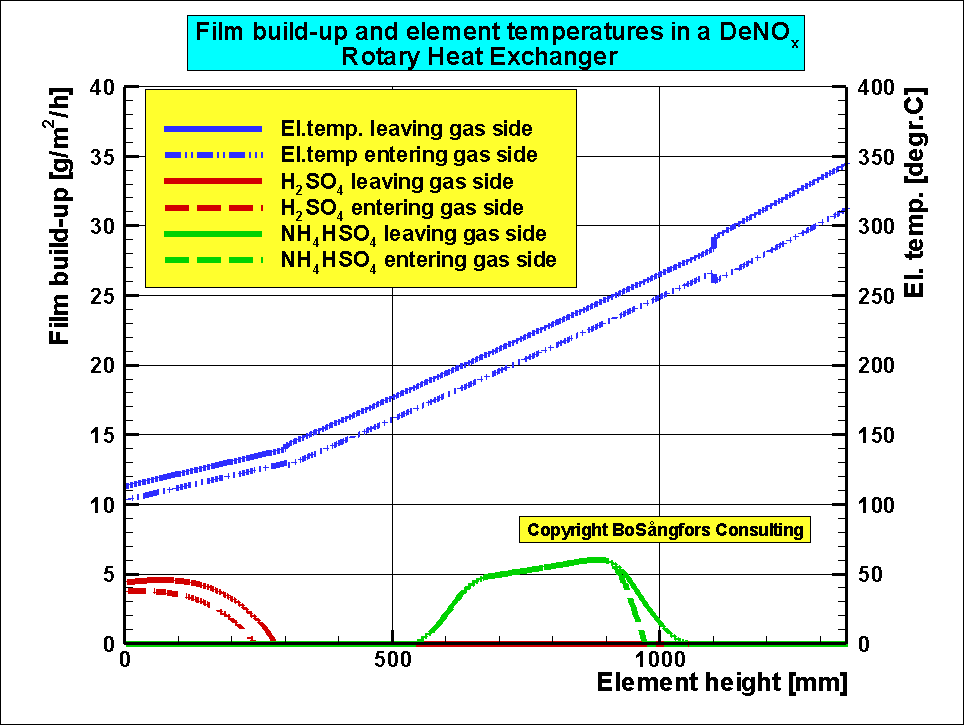

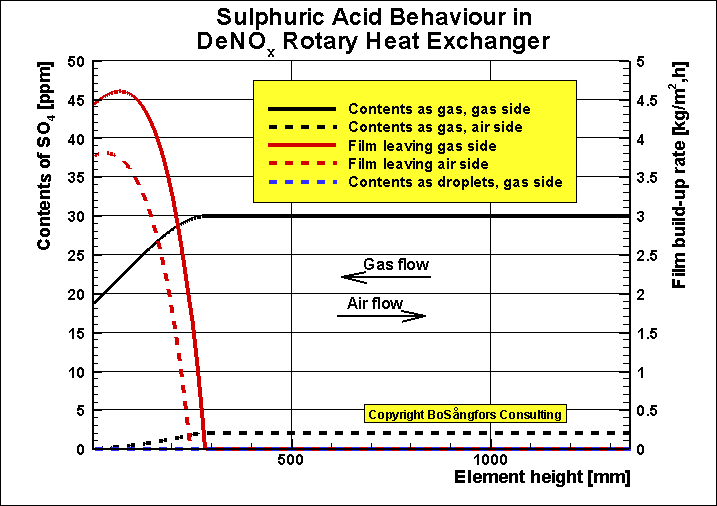

BoSๅngfors Consulting, Sweden

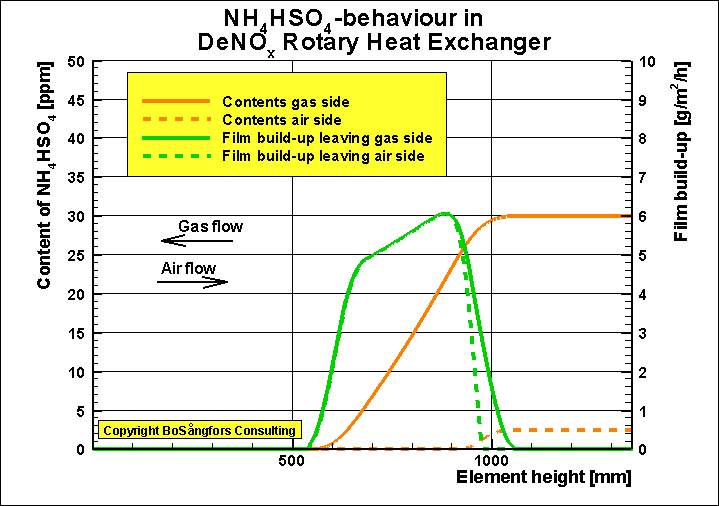

Calculation of

Temperatures and Film Build-up in a DeNOx Heat Exchanger.

This type of Rotary Heat Exchanger (so called Ljungstr๖m) is operating under equal conditions at Karlshamn Power Station, Karlshamn, Sweden

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

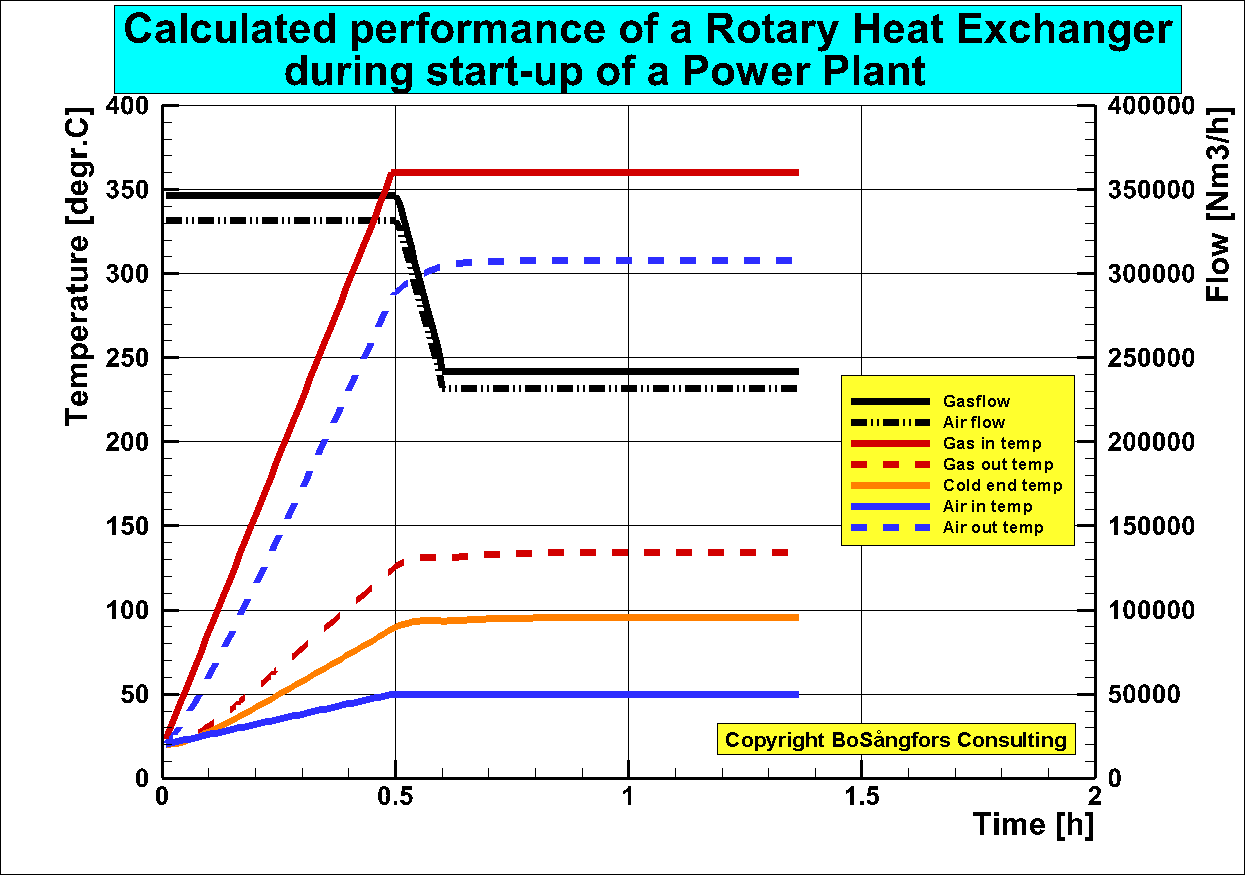

BoSๅngfors Consulting, Sweden

Calculated

Performance of a Rotary Heat Exchanger during start-up in a Power Plant

NOTE: When the flue gas contains for instance sulphuric acid it is necessary to start with high excess air. By doing that you get a smaller concentration of sulphuric acid in the flue gas and a lower condensation temperature. Then you avoid condensation deep into the heat transfer elements.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

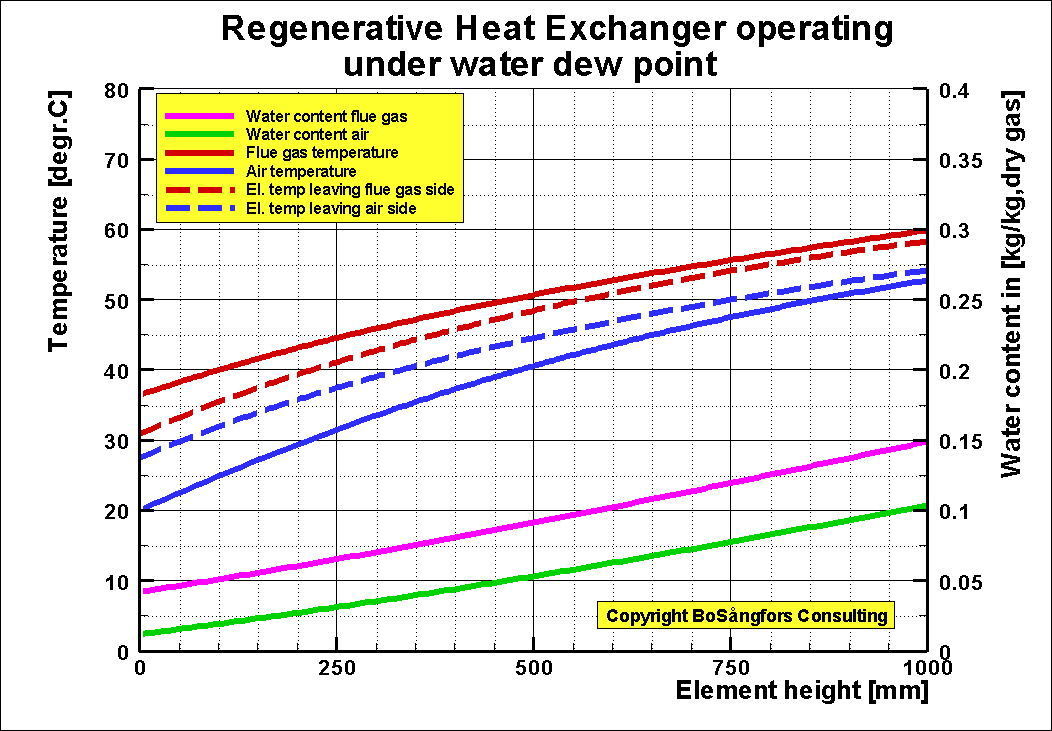

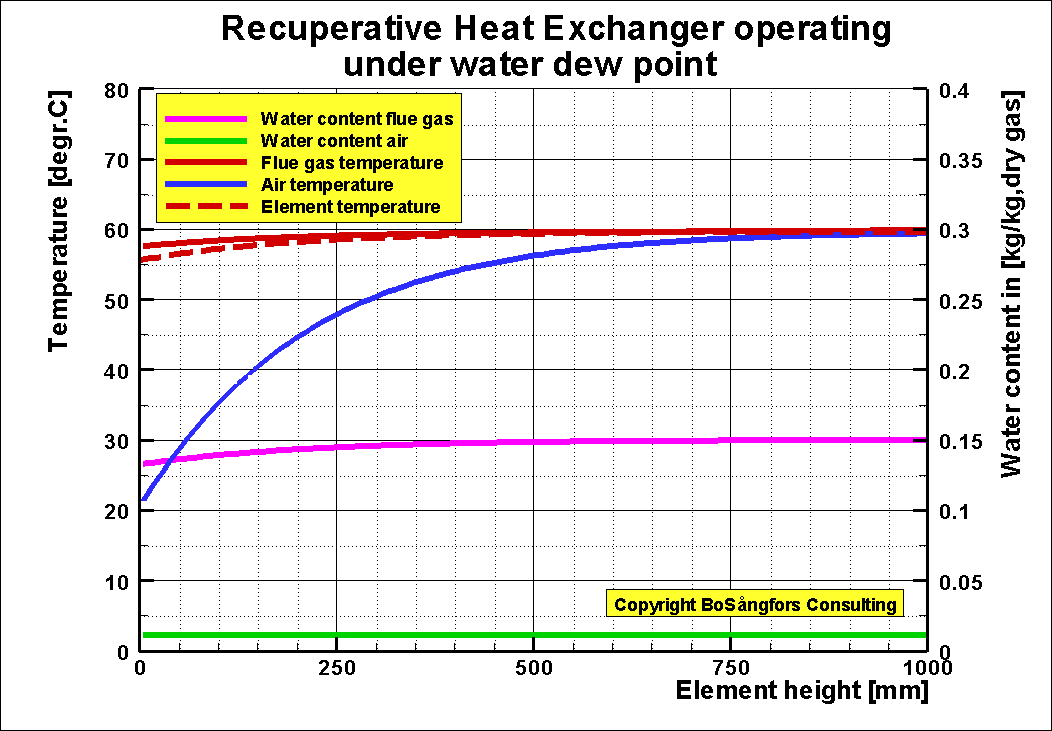

Temperatures and Water content in Regenerative resp. Recuperative Heat Exchanger operating under water dew point.

Inlet condition = Flue gas with water spray injection.

Flue gas inlet temperature = Water dew point temperature

Please also look at: http://www.freepatentsonline.com/5482108.html

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

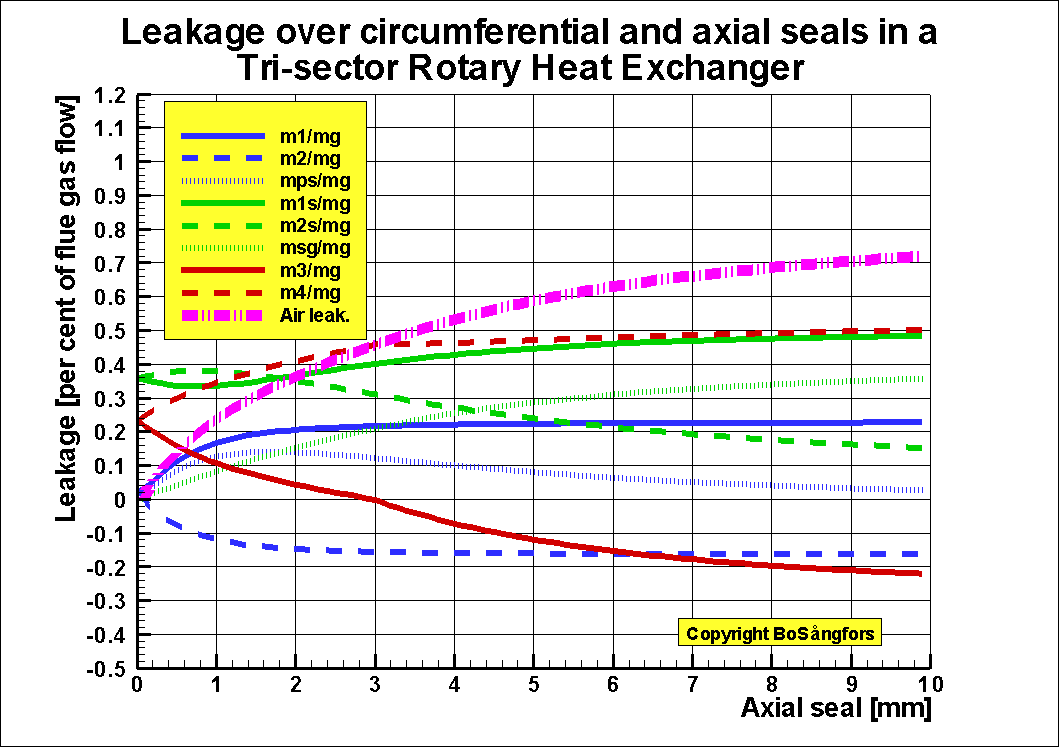

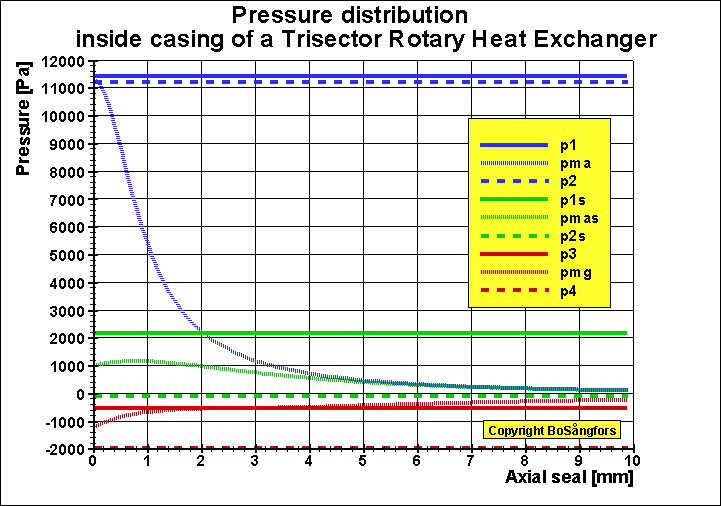

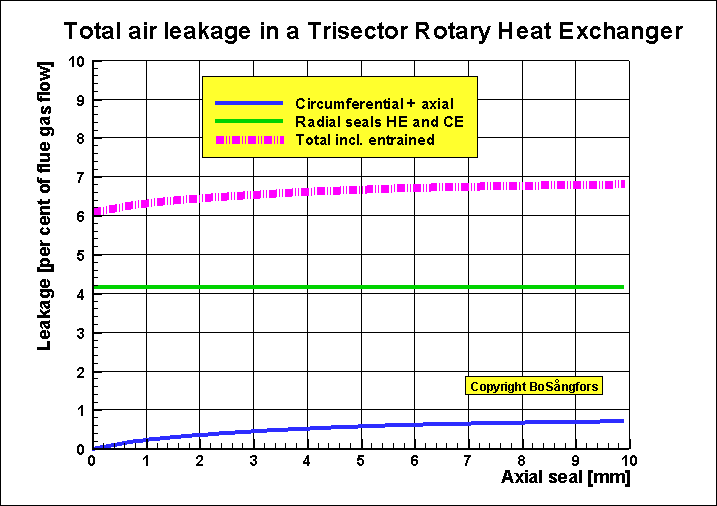

Leakage analysis of a Tri-sector Rotary Heat Exchanger.

Rotor diameter = 8.283 m

Rotor height = 2.143 m

Rotor speed =

2 rpm

Element

porosity = 0.84

Flue gas flow = 454183 kg/h

Air sector primary = 30 degree.

Air sector secondary = 150 degree.

Gas sector = 180 degree.

PRESSURES [Pa]

Air in primary P1= 11442

Air out primary P2= 11234

Air in secondary P1s= 2179

Air out secondaryP2s= -79

Gas in P3= -497

Gas out P4 = -1942

CIRCUMFERENTIAL SEAL CLEARANCES [mm]

Primary in S1= 1

Primary out S2= 1

Secondary in S1s=1

Secondary outS2s=1

Gas in S3=1

Gas out S4=1

TEMPERATURES [degr.C]

Air in

primary T1=50

Air out

primary T2=372

Air in

secondary T1s=55

Air out

secondary T2s=357

Gas in T3=390

SECTOR PLATE

CLEARANCES [mm]

Cold end =2

Hot end =2

NOMENCLATURE (diagrams)

pma = pressure in volume between

casing and rotor, primary air [Pa]

pmas = pressure in volume between

casing and rotor, secondary air [Pa]

pmg = pressure in volume between

casing and rotor, gas [Pa]

m1 = flow over circumferential seal

primary inlet air [kg/h]

m2 = flow over circumferential seal

primary outlet air [kg/h]

mps = flow over axial seal from

primary to secondary [kg/h]

m1s = flow over circumferential seal

secondary to gas [kg/h]

m2s = flow over circumferential seal

secondary outlet air [kg/h]

msg= flow over axial seal from

primary to gas [kg/h]

m3 = flow over circumferential seal

inlet gas, [kg/h]

m4 = flow over circumferential seal

outlet gas, [kg/h]

mg = flue gas flow [kg/h]

Air leak = Air leakage into gas [per cent of flue gas mass flow]

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

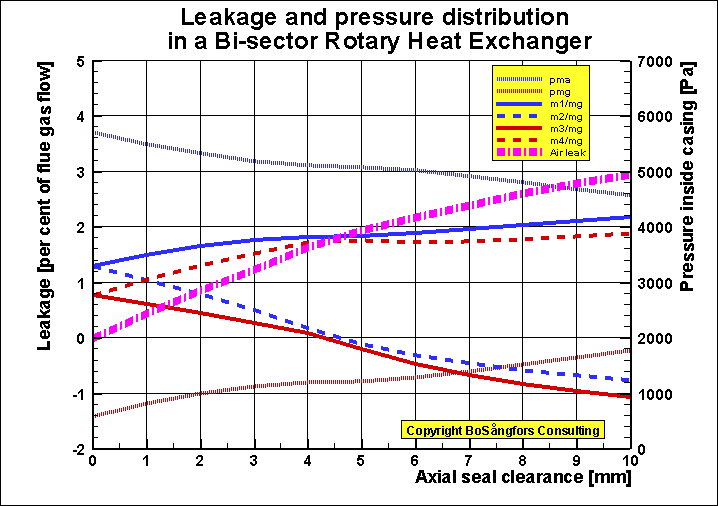

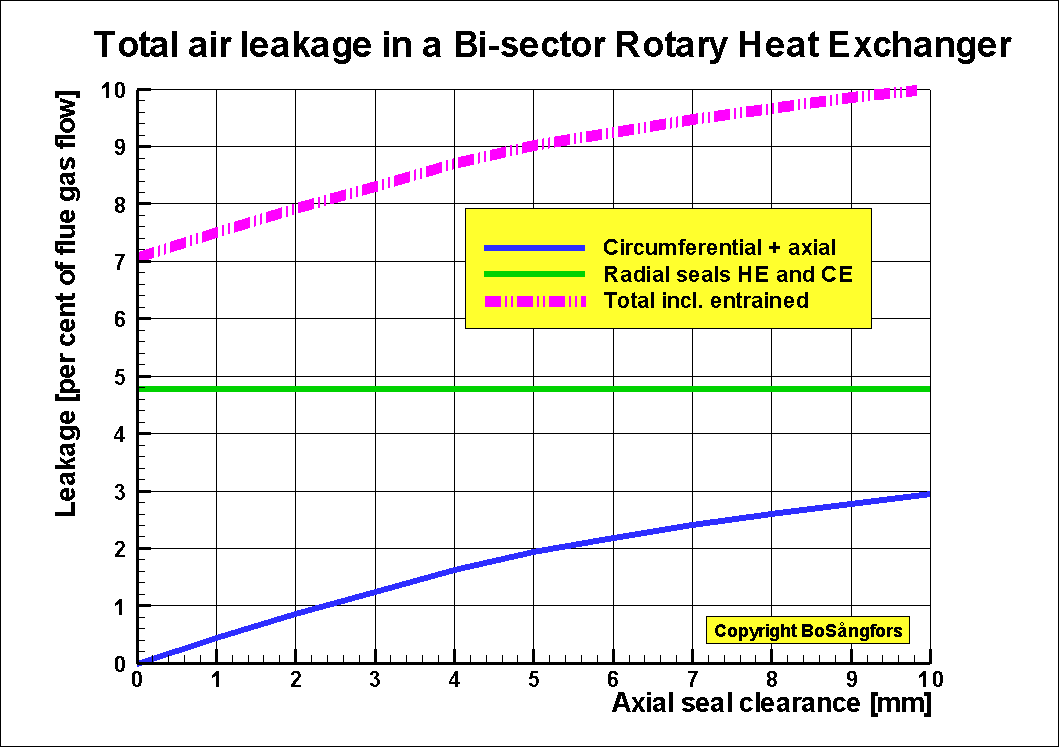

Leakage analysis of a Bi-sector Rotary Heat Exchanger.

Rotor diameter = 7.48 m

Rotor height = 1.83 m

Rotor speed =

2 rpm

Element

porosity = 0.84

Flue gas flow = 242000 kg/h

Air sector = 180 degree.

Gas sector = 180 degree.

PRESSURES [Pa]

Air in P1= 6325

Air out P2= 5099

Gas in P3=

1216

Gas out P4= 0

CIRCUMFERENTIAL SEAL CLEARANCES [mm]

Air in S1= 2.5

Air out S2= 2.5

Gas in S3= 2.5

Gas out S4= 2.5

TEMPERATURES [degr.C]

Air in T1=40

Air out

T2=502

Gas in T3=601

SECTOR PLATE

CLEARANCES [mm]

Cold end =3

Hot end =3

NOMENCLATURE (diagrams)

pma = pressure in volume between

casing and rotor, air side, [Pa]

pmg = pressure in volume between

casing and rotor, gas side, [Pa]

m1 = flow over circumferential seal

inlet air, [kg/h]

m2 = flow over circumferential seal

outlet air, [kg/h]

m3 = flow over circumferential seal

inlet gas, [kg/h]

m4 = flow over circumferential seal

outlet gas, [kg/h]

mg = flue gas flow [kg/h]

Air leak = Air leakage into gas [per cent of flue gas mass flow]

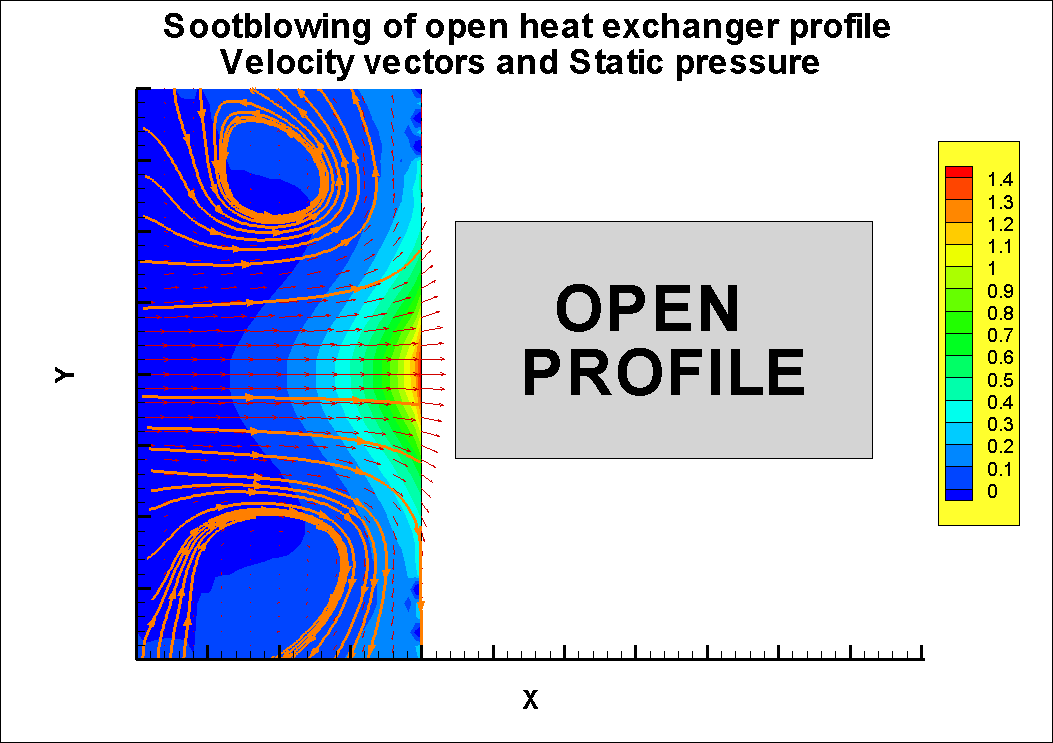

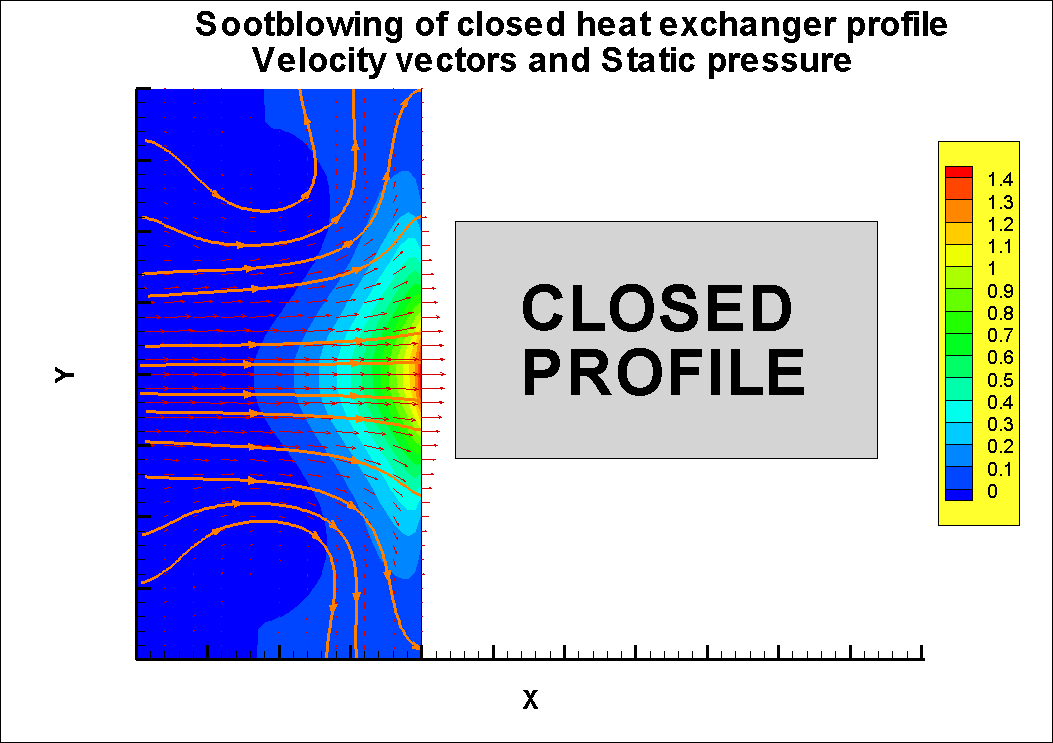

BoSๅngfors Consulting, Sweden

Sootblowing of open and closed element profiles for Heat Exchangers.

ญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญญ

BoSๅngfors Consulting, Sweden

Calculation of Temperatures in a CrossFlowHeat Exchanger.

Bes๖kare totalt:

Bes๖kare denna mๅnad:

Bes๖kare denna vecka:

Bes๖kare idag:

http://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=2442&context=iracc

Now I changed the second stage from Screw Expander to a R245faTurbine.

The performance is the same, but the turbine is a smaller machine than a Screw Expander.

.

The article: